Resource Highlights

In this article, you will find information regarding the A/C expansion valves. Her we take a look at why does it fail, symptoms of failure and why it’s important to replace the A/C expansion valves.

Just like any valve, the expansion valve is responsible for controlling the flow of fluid - in this case the refrigerant - the lifeblood of the A/C system. So, when this part fails, so does the rest of the system, because it can no longer regulate this vital ingredient. Here we give you some simple advice, to ensure this doesn’t happen to you and your customers.

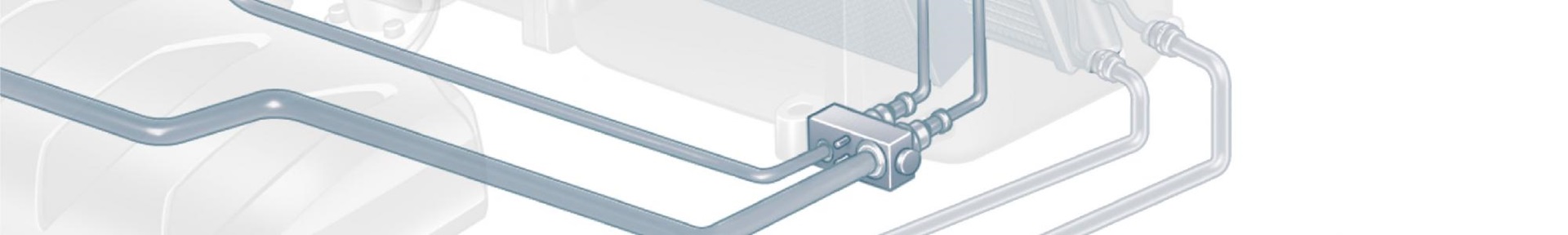

The primary job of the expansion valve is to make sure the flow of refrigerant throughout the A/C system is just right, based on the temperature of the evaporator and the demand on the system. Too much and the core of the evaporator will get too cold and eventually freeze over. Not enough, and the opposite could happen - it could get too hot and overheat. Positioned between the high- and low-pressure sides of the system, it also acts a go between; taking a high-pressure liquid, and as it passes through its narrow interior, transforming it into a low-pressure liquid.

Why does it fail?

The expansion valve operates under high pressure and temperatures and is therefore susceptible to issues. For example, mechanical failure of the rod can cause the valve to stick in the full or partially open or closed position. Alternatively, the sensing bulb that measures the temperature at the evaporators outlet and sends a signal to the valve can fail. Like most A/C components, when the system is opened to replace a part, contaminants can also enter causing premature wear or blockage of the valve’s very narrow interior.

Symptoms of failure

When the expansion valve stops working properly, so will the A/C system, producing a number of symptoms that can alert the driver to a possible fault. These are:

- Underperforming A/C system: since the expansion valve controls the flow, the A/C may begin to blow noticeably less cold than before, or even warm air in some instances.

- Frost on the vents: although it’s designed to cool, this should never be to the point where it’s too cold or frost is forming on the vents. If this happens it’s a sure sign too much refrigerant is being supplied to the evaporator, causing the core to frost over.

- Compressor constantly running: similarly, if the valve is permanently stuck open, refrigerant will be pumped into the system continuously, placing unnecessary strain on the compressor and other system components.

- Inconsistent airflow: the inability of the valve to regulate may also cause an inconsistent airflow with the temperature alternating between cool and warm.

Why it’s important to replace

Since a faulty expansion valve will ultimately result in the failure of the complete A/C system, and potentially irreversible damage to key components, it’s important to replace it as early as possible with a quality part such as Delphi. Leveraging our rich OE heritage and expertise, every one of our expansion valves is manufactured to exacting OE standards and undergoes stringent testing including vibration, pressure, noise, hardness and speed. The range includes more than 65 parts, with 23 new part numbers, fitted to popular applications such as Ford Max, EcoSport and Opel Mokka added in 2019.

SIGN UP

TO FIND OUT MORE

Fill out your details to hear more from our experts and get the latest updates from Delphi.