Rubber-to-Metal Parts

- Product Information

- Product Resources

- Enquire

- Related Products

Broad range

Today’s modern vehicles contain many different rubber-to-metal components, which is why we’re focused on the continued development of our range. Our current line-up includes control arm and suspension mount bushes, anti-roll bar bushes and engine mounts … with more to come.

The right material

Rubber-to-metal components are subject to high dynamic stresses day-in, day-out. And is why we only ever use the highest quality materials. By carefully balancing the precise quantities of steel and rubber, our rubber-to-metal parts provide the optimum combination of strength, flexibility and noise reduction, tailored to the application they fit.

Preparation is key

To ensure a perfect bond between rubber and metal, both materials go through a rigorous cleaning process. All bonding surfaces are washed, sanded, degreased and painted. And that’s just the start.

Super strong bond

For superior mechanical properties, we chemically bond the rubber to a pre-coated metal surface. Under high temperatures and pressure, the adhesive reacts to provide a powerful bond between the rubber and metal part – so much so, that the rubber should tear before the bond breaks.

Pushed to the limit

We know our parts are strong and durable, but just to be sure, we subject them to extensive fatigue testing. We also conduct push tests to check the cohesion of the rubber to metal. As a rule, OE push out levels for bushes are 1000 Nm of pressure minimum. Ours can withstand 1800 Nm.

Three-year warranty

Available in UK only. Like all our steering parts, our rubber-to-metal range comes with a three-year or 36,000-mile warranty. So you can fit Delphi with complete confidence, for an OE quality repair you know will last.

Rubber to Metal Durability Test

- Confirms the integrity of the part design and manufacturing process used to make it.

- After 220,000 test cycles, the Delphi bush remained intact with a small amount of rubber cracking.

- In contrast, one competitor suffered a complete failure of the bonding in less than 30,000 cycles.

- This can result in the failure of the component assembly into which it is installed.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

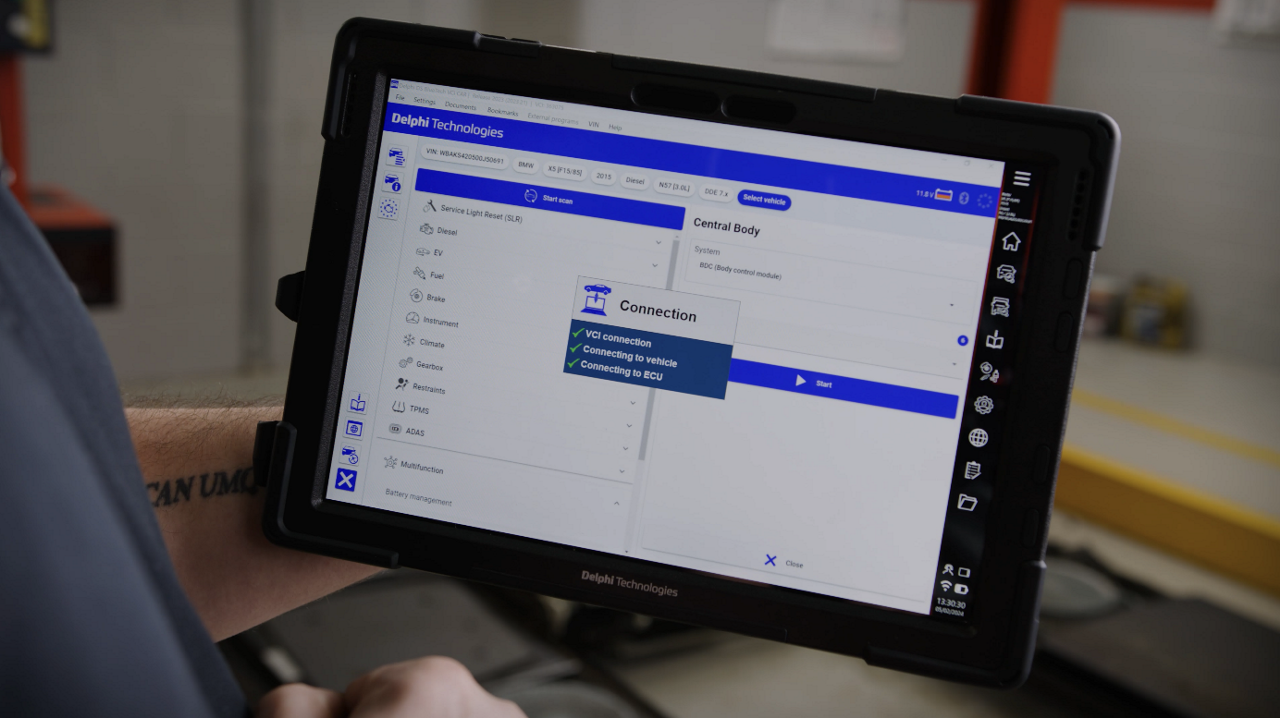

Support through tools, tips and training

Related product resources and downloads

Register to our Technician portal for access to downloads & additional services

Get in touch

The full Delphi Steering & Suspension product range

Find out where to buy Delphi parts