Diesel Particulate Filters

Increasingly stringent emissions legislation continues to drive the demand for cleaner, greener and more fuel efficient vehicles. To meet these challenges, the Diesel Particulate Filter, or DPF, is designed to remove diesel particulate matter or soot from the exhaust gas of a diesel engine.

- Critical to the longevity of green performing diesel engines

- Manufactured with silicon carbide

- Allows multiple regeneration cycles at temperatures over 600˚

- Wash coat of precious metals, enabling combustion at the best possible temperature

- Backed by Delphi OE expertise, training, technical support and diagnostics

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In part one, we spoke about the key trends influencing the growth of hybrid and electric vehicles (HEVs). In the second of our two-part series, we explore what this means to the aftermarket. And how with the help of an OE provider, like Delphi, you can take advantage of this fast-growing service opportunity.

In part one, we spoke about the key trends influencing the growth of hybrid and electric vehicles (HEVs). In the second of our two-part series, we explore what this means to the aftermarket. And how with the help of an OE provider, like Delphi, you can take advantage of this fast-growing service opportunity.

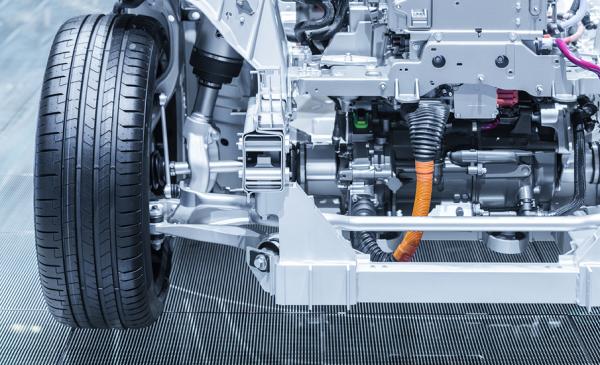

Driven by increasingly stringent carbon dioxide (CO2) emissions legislation, government incentives, falling costs and improvements in both driving range and vehicle charging time, the number of HEVs on Europe’s road will pass the four million mark this year. Although still a small share (around 1% of the European car parc), compared with their internal combustion engine powered counterparts, recent announcements from some of the biggest vehicle manufacturers outlining their plans for electrification could see a much bigger shift, bringing HEVs to the roads in unprecedented numbers during the next decade.

Volvo, for example, confirmed its intention to go all electric by 2019, becoming the first major car manufacturer to do so. Jaguar Land Rover plans to electrify its entire vehicle line-up by 2020, and Mercedes-Benz, a couple of years later. Other manufacturers have made similar pledges. Indeed, by 2025, more than half of European vehicle production will be electrified in some form or another - whether a hybrid, plug-in hybrid or full electric vehicle - growing to 70 percent by 2030. Over time, this will translate into a significant service opportunity for the aftermarket. But what about now?

HEV technology is not just about the future. It’s here now! First-generation cars, such as the Toyota Prius and Nissan Leaf, have been around for many years. And in good numbers, presenting immediate opportunities for those garages with the capability to service them.

To start, HEVs still have traditional wear and tear components such as brakes, air conditioning, steering. And just like any other vehicle these will need regular maintenance. Whilst in theory some of these parts may wear less, in practice they just wear differently. Take regenerative braking as an example. Because the hydraulic brakes are used less, rust and contaminants can build-up, affecting both the disc’s friction surface, the pad mounting, and caliper piston/slider pins. Other parts, however, will wear exactly the same as they do on their petrol or diesel equivalents.

Despite electric cars having fewer moving parts than conventional vehicles, there are also new ones such as batteries, electric drive motors, inverter assemblies and converters, which will wear out and eventually fail. Take the high voltage battery. Much like a battery in a smartphone or tablet, it will gradually lose its ability to hold a charge, meaning the more you drive it, the shorter its driving range will become. To the point, it will need to be replaced. And when this happens, that means a high-value repair.

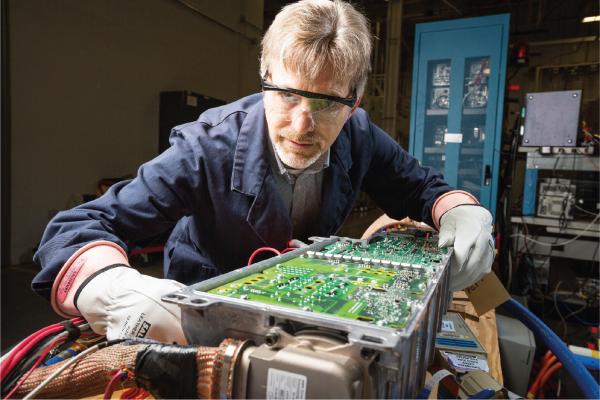

The increasing electronic content will require new diagnostic competencies, too. For instance, it’s not uncommon for owners of older hybrid cars to report a loss in performance as a result of dendrite build-up – thin, finger like projections of lithium that grow from one electrode to the other, reducing both the battery’s capacity and lifespan. To remedy this, a forced charge will need to be carried out on the high-voltage battery using a quality OBD diagnostic tool. Yet, another new service garages can offer their customers.

To take advantage of these opportunities, both today and tomorrow, independent garages will need access to the right parts, equipment and know-how. And that’s where we can help….

Today, our OE portfolio includes engine control units, transmission control units, power distribution units, local control units, engine management systems and hybrid systems, inverters, converters, high voltage boxes, battery pack controllers, supervisory controllers (hybrid control units), on-board battery chargers and battery controllers. And as demand for the replacement parts grow, we’ll introduce these to our aftermarket range too.

We also understand the challenges when it comes to servicing these vehicles. For example, our two-day, hybrid technology training programme, accredited in the UK by the Institute of the Motor Industry, provides technicians with the in-depth knowledge and expertise they need to work safely and efficiently on hybrid vehicles.

And at a time when many independent garages continue to shy away from working on HEVs due to the perceived dangers associated with higher voltage vehicles, those that invest now will have a distinct competitive advantage. By being one of the first to enter this fast-growing market, business savvy garages will be able to position themselves as experts and reap the rewards that come with it. Namely increased revenue and profit, market share growth and strong brand recognition and customer loyalty. We think of that as a pretty electric opportunity!

Visit our Technician Library for access to Documents and Downloads

Get in touch

Find out where to buy Delphi Technologies parts