Diesel Particulate Filters

Increasingly stringent emissions legislation continues to drive the demand for cleaner, greener and more fuel efficient vehicles. To meet these challenges, the Diesel Particulate Filter, or DPF, is designed to remove diesel particulate matter or soot from the exhaust gas of a diesel engine.

- Critical to the longevity of green performing diesel engines

- Manufactured with silicon carbide

- Allows multiple regeneration cycles at temperatures over 600˚

- Wash coat of precious metals, enabling combustion at the best possible temperature

- Backed by Delphi OE expertise, training, technical support and diagnostics

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article you will obtain technical tips for the Turbo VGT.

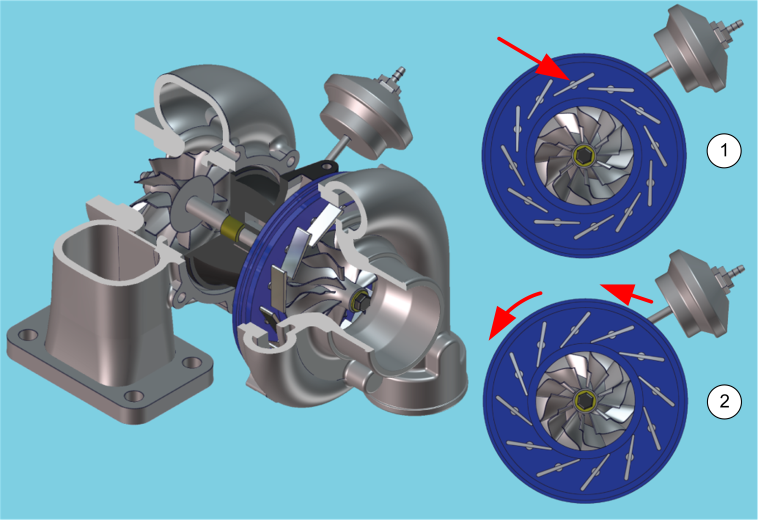

Tech Tip Turbo VGT | A small turbo responds quickly and is effective at low rpm. However, it cannot deliver the high flow at high rpm. On the other hand, a large turbo can deliver the high speed flow, but will be slower to respond. This leads to unacceptable response times ("turbo lag"). The VGT has a wider effective range. Varying the turbo vane position allows the turbo to be in small or large capacity configurations. These vanes are managed by an electronic unit. |

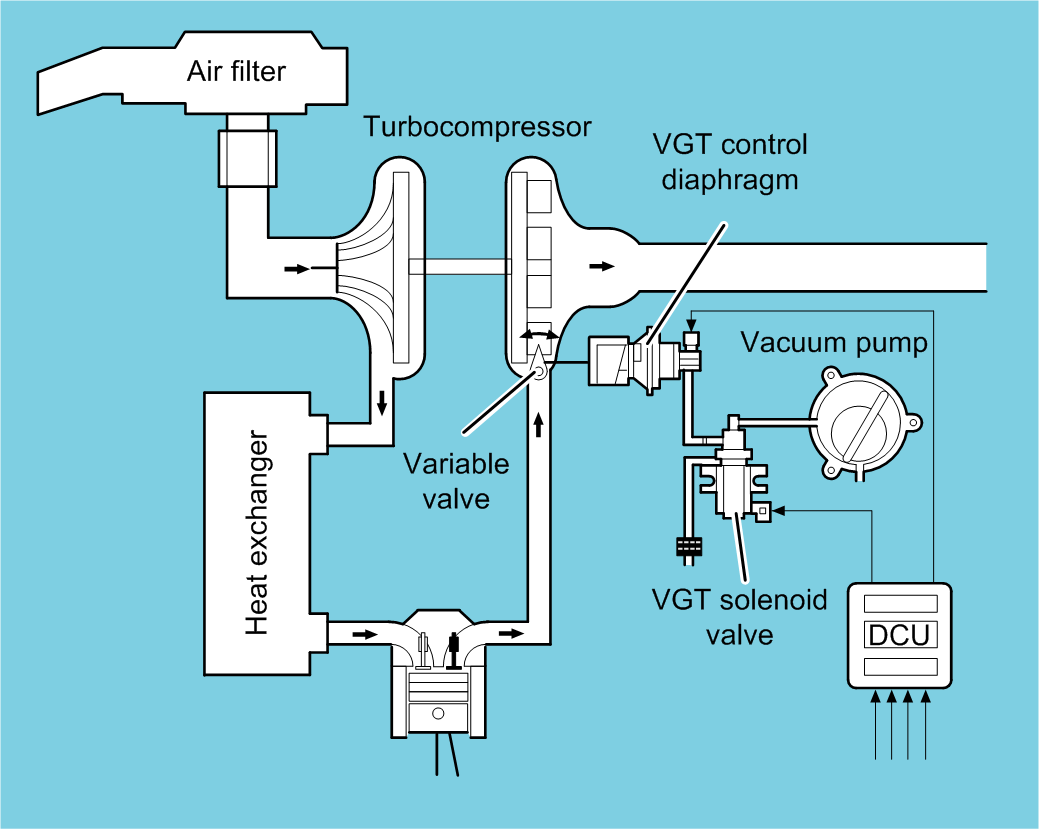

Strategy | The limitation of the boost setting depends on two maps (engine speed- atmospheric pressure and engine speed - air temperature). A strategy allows detection and warning of any fault which may destroy the turbo. The DCU compares the air flow and the engine speed to check consistency. If a fault is detected, the DCU activates a recovery mode (reduced flow) to protect the system. The "overboost" function is activated according to engine speed variation and requested load criteria. |

Two stage VGT | The two stage turbo is managed by 3 pneumatic actuators (diaphragm). The following sensors are present:

|

Visit our Technician Library for access to Documents and Downloads

Get in touch

Find out where to buy Delphi Technologies parts