Mass Air Flow Sensors

- Product Information

- Product Resources

- Enquire

- Related Products

Innovative OE design

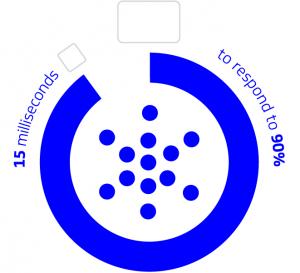

We build our OE expertise into every MAF sensor we make. Featuring a proprietary temperature compensation design, they offer outstanding performance over a wide range of ambient temperatures. And are fast to respond to changing engine conditions – typically less than 15 milliseconds to respond to 90 percent of a flow change. Innovative, dual-heated elements on specific references also help to ensure optimal performance, fuel efficiency, and reduced emissions

OE engineered and tested

By testing and calibrating to OE specifications, our MAF sensors provide the same accurate readings and airflow output as the OE. Each sensor is tested on state-of-the-art sonic nozzle-testing equipment capturing over 6,000 data points per flow, for optimal calibration accuracy. They’re also flow tested to match the OE for signal stability (noise), temperature compensation (the ability of the MAF sensor to measure airflow accurately from -30°C to 70°C) and electromagnetic compatibility.

Never remanufactured MAF sensor

Some things are better new. That’s why every sensor we make – whether with or without the housing—is built with all-new components and never remanufactured. Remanufactured MAFs are simply cleaned and tested, so any contamination on the sensor may not be eliminated, resulting in inaccurate readings to the ECU.

Greener probe-only technology

It’s often the electronics on the sensor probe that fail, meaning it’s not always necessary to replace the complete part. So we developed a probe-only solution, in addition to a full range of complete units. By eliminating the plastic housing, this provides a greener, more cost-effective and faster repair option.

The complete package

With Delphi you get access to the complete package: the range, advanced DS diagnostics including the ability to look at live data, both at idle and max RPM, to determine if the MAF sensor is reporting the correct data, expert training and support and vehicle technical information including wiring diagrams, component locations and guided diagnostic procedures.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we take a closer look at the key engine management components and the important role that each of them plays.

The engine management system is arguably one of the smartest systems in today's vehicle. After all it is responsible for the entire combustion process – mixing the right amount of fuel to the air entering the engine and igniting the compressed air/fuel mixture in the cylinder – more than earning its reputation as the brains of the car. In fact, the engine management system is where traditionally the most advanced vehicle technologies are found, operating 30 plus components and approximately 50 computer modules to deliver the millions of lines of code that keeps the vehicle running efficiently.

But what exactly is the Engine Management System? Here we take a closer look at the key engine management components and the important role that each of them plays.

Engine Control Unit: Controlling the engine is the most processor-intensive job on any car and that’s all down to the Engine Control Unit, more commonly known as the ECU or PCM. Using the data it receives from the multitude of sensors located on the engine, the ECU knows everything there is to know about the engine; from the speed and temperature of the intake air to the amount of oxygen in the exhaust. It then processes this data, performing millions of calculations every second, to determine how each sensor should respond in order to achieve the very best engine performance, emissions and fuel economy.

The sensors that the ECU monitors include:

Oxygen sensor: measures oxygen levels in the exhaust gases emitted by the engine to fine tune the air/fuel ratio for reduced emissions.

Coolant temperature sensor: measures engine temperature to monitor a range of fuel, ignition and emission control functions.

Mass air flow (MAF) sensor: monitors how much air is entering the system to determine the required fuel mixture.

Manifold absolute pressure (MAP) sensor: records intake vacuum for accurate ignition timing and fuel delivery.

Throttle position sensor: determines the position of the gas pedal to adjust spark timing and fuel mixture in line with changes in engine load.

Camshaft sensor: measures camshaft speed and the resultant position of each piston to control ignition and fuel injection timing.

Crankshaft sensor: measures engine RPM to determine relative position of the crankshaft for controlled spark timing and fuel delivery.

Knock sensor: detects engine knocking and subsequently retards timing while the engine is under load to protect the engine against spark knock.

Exhaust gas temperature sensor: protects components exposed to the flow of hot exhaust gas from overheating by instructing the ECU to lower the temperature. Also establishes the optimum temperature for DPF regeneration in diesel vehicles.

ABS sensor: monitors the wheel speed to prevent the brakes from locking and avoid uncontrolled skidding.

Transmission speed sensor: calculates which gear the transmission should engage for efficient driving

Oil pressure switch: monitors engine oil pressure levels and activates oil warning light where required.

DPF sensor: used in diesel vehicles to monitor and minimize the amount of soot emitted from the exhaust.

As a leading OE manufacturer we are continually developing breakthrough sensing and actuating solutions to help optimize emissions control, fuel economy, and drivability. In addition to the above parts, we offer diagnostic tooling, training and technical support for a full aftermarket solution.

Get in touch

The full Delphi Sensors product range

Find out where to buy Delphi parts