Mass Air Flow Sensors

- Product Information

- Product Resources

- Enquire

- Related Products

Innovative OE design

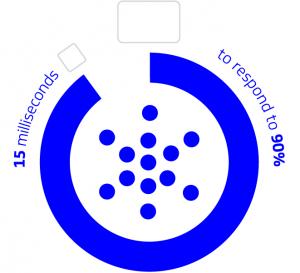

We build our OE expertise into every MAF sensor we make. Featuring a proprietary temperature compensation design, they offer outstanding performance over a wide range of ambient temperatures. And are fast to respond to changing engine conditions – typically less than 15 milliseconds to respond to 90 percent of a flow change. Innovative, dual-heated elements on specific references also help to ensure optimal performance, fuel efficiency, and reduced emissions

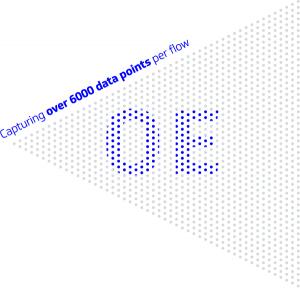

OE engineered and tested

By testing and calibrating to OE specifications, our MAF sensors provide the same accurate readings and airflow output as the OE. Each sensor is tested on state-of-the-art sonic nozzle-testing equipment capturing over 6,000 data points per flow, for optimal calibration accuracy. They’re also flow tested to match the OE for signal stability (noise), temperature compensation (the ability of the MAF sensor to measure airflow accurately from -30°C to 70°C) and electromagnetic compatibility.

Never remanufactured MAF sensor

Some things are better new. That’s why every sensor we make – whether with or without the housing—is built with all-new components and never remanufactured. Remanufactured MAFs are simply cleaned and tested, so any contamination on the sensor may not be eliminated, resulting in inaccurate readings to the ECU.

Greener probe-only technology

It’s often the electronics on the sensor probe that fail, meaning it’s not always necessary to replace the complete part. So we developed a probe-only solution, in addition to a full range of complete units. By eliminating the plastic housing, this provides a greener, more cost-effective and faster repair option.

The complete package

With Delphi you get access to the complete package: the range, advanced DS diagnostics including the ability to look at live data, both at idle and max RPM, to determine if the MAF sensor is reporting the correct data, expert training and support and vehicle technical information including wiring diagrams, component locations and guided diagnostic procedures.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article you will find out about the exhaust gas temperature sensor:

- What is an exhaust gas temperature sensor?

- How do exhaust gas temperature sensors work?

- Why do exhaust gas temperature sensors fail?

- What are the symptoms of a faulty exhaust gas temperature sensor?

- How do I troubleshoot an exhaust gas temperature sensor?

- What are common exhaust gas temperature sensor fault codes?

- How do I replace an exhaust gas temperature sensor?

Thanks to ever-stringent emissions legislation, exhaust gas temperature sensors are becoming increasingly popular in modern vehicles. And because they’re a high failure part, they’re becoming an increasingly popular repair too. Here we explain what the exhaust gas temperature sensor does, why and how it fails, and how to replace it so you can take advantage of this fast-growing service opportunity with a quality, best-practice repair.

What is an exhaust gas temperature sensor?

As its name suggests, the exhaust gas temperature sensor measures the temperature of the exhaust gas. This information is then relayed back to the engine control unit or ECU, where appropriate action is taken. In petrol engines, its main role is to protect key components from the higher temperatures common with downsized engines – so if the sensor detects excessive temperatures, the ECU will reduce the temperature, by lowering boost pressure in the case of the turbocharger, for example, or increasing the quantity of fuel injected for the catalytic converter. In diesel engines, exhaust gas temperature sensors are also used to monitor the temperature of the diesel particulate filter (DPF) to establish the correct temperature for regeneration, reducing harmful emissions. It is not uncommon to have three or more sensors fitted to the exhaust; one prior to the turbocharger, one before the DPF and the third after the particulate filter.

How do exhaust gas temperature sensors work?

There are two types of exhaust gas temperature sensors; one with a positive temperature coefficient (PTC) sensing element, and the other a negative temperature coefficient (NTC), the only difference being how they measure the temperature. The NTC element has a high resistance at low temperatures and a low resistance at high temperatures. In other words, its resistance decreases as the temperature increases. Whereas in a PTC element, the most common type, resistance increases in line with temperature. Either way a temperature is assigned to the resistance in the ECU and action taken accordingly.

Why do exhaust gas temperature sensors fail?

One of the common causes of exhaust gas temperature sensor failure is exposure to excessively high temperatures – over 900°C in some case - the very thing they protect other components from. Like all wired sensors, severe vibration can also loosen internal connections and any bends or twists can cause the wire to break, making them particularly vulnerable to damage when replacing other components in the exhaust system. These, alongside contamination from other fluids such as oil or antifreeze, can all affect the sensor’s response characteristics, causing it to drift out of tolerance and provide inaccurate readings.

What are the symptoms of a faulty exhaust gas temperature sensor?

A faulty exhaust gas temperature sensor can negatively affect a vehicle’s after-treatment system, resulting in the following symptoms:

- Check engine light: if the ECU detects a problem with the sensor or signal, it will trigger the check engine light to come on.

- Reduced fuel efficiency: if the sensor relays incorrect voltages, the DPF regeneration process can take longer, resulting in increased fuel usage.

- Unnecessary DPF regeneration: faulty sensors can also lead to unnecessary regenerations, causing inconvenience to the vehicle owner.

- Failed emissions test: a false reading can cause the EGR system to malfunction, without triggering the check engine light. This can result in an emissions test fail.

- Component failure: increases in exhaust temperatures can also contribute to the premature failure of other exhaust or internal engine components.

How do I troubleshoot an exhaust gas temperature sensor?

To diagnose a faulty exhaust gas temperature sensor, consider the following steps:

- Conduct an electronic test and read any fault codes using a diagnostic tool.

- Inspect the connectors for signs of corrosion or loose connections.

- Check the wiring for any breaks or damage that could cause a short to the ground.

- Inspect the sensor for any build-up of contaminants and clean with a clean, dry cloth as required.

- To test the sensor, use a separate IR measurement device, and compare the readings to the live data obtained when using a diagnostic tool. Run the engine so the exhaust increases in temperature and compare the readings.

- With vehicle ignition turned on, and the plug on the EGT sensor disconnected, measure the voltage at the sensor’s connector – there should be 5 volts. If not, then trace the wire back to the ECU and check supply there.

What are common exhaust gas temperature sensor fault codes?

Common fault codes include:

- P0544: Exhaust gas temperature sensor, bank 1, sensor 1 - circuit malfunction

- P0546: Exhaust gas temperature sensor, bank 1, sensor 1 - high input

- P2033: Exhaust gas temperature bank 1, sensor 2 - circuit high

- P247A: Exhaust gas temperature sensor bank 1, sensor 3 – out of range

- P0549: Exhaust gas temperature sensor, bank 2, sensor 1 - circuit high

- P2031: Exhaust gas temperature bank 1, sensor 2 - circuit malfunction

Note, by design, PTC sensors will continue to relay misinformation to the ECU without setting a diagnostic fault code.

How do I replace an exhaust gas temperature sensor?

If the exhaust gas temperature is faulty, then it needs to be replaced – simply follow the best-practice advice:

- Locate the faulty sensor. Note the position can vary depending on their function; either upstream or downstream of the turbocharger, catalytic converter and DPF and within the NOX reduction system.

- Next disconnect the electrical connector and unscrew the sensor using a socket wrench, taking care not to damage nearby components.

- Prepare the new sensor, applying anti-seize compound to the thread where necessary. Handle carefully to prevent damage to the component.

- Install the new exhaust gas temperature sensor and torque tighten to vehicle manufacturer’s recommendations.

- Refit the electrical connector, then the negative battery terminal.

- Now reconnect the diagnostic tool and delete any related fault codes.

- Turn the ignition on and confirm that the check engine light is extinguished and that the exhaust system is functioning correctly.

- Finally, perform a road test.

Get in touch

The full Delphi Sensors product range

Find out where to buy Delphi parts