Mass Air Flow Sensors

- Product Information

- Product Resources

- Enquire

- Related Products

Innovative OE design

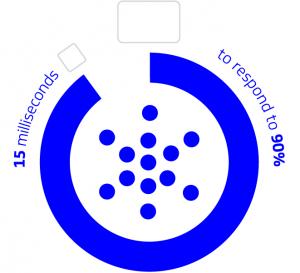

We build our OE expertise into every MAF sensor we make. Featuring a proprietary temperature compensation design, they offer outstanding performance over a wide range of ambient temperatures. And are fast to respond to changing engine conditions – typically less than 15 milliseconds to respond to 90 percent of a flow change. Innovative, dual-heated elements on specific references also help to ensure optimal performance, fuel efficiency, and reduced emissions

OE engineered and tested

By testing and calibrating to OE specifications, our MAF sensors provide the same accurate readings and airflow output as the OE. Each sensor is tested on state-of-the-art sonic nozzle-testing equipment capturing over 6,000 data points per flow, for optimal calibration accuracy. They’re also flow tested to match the OE for signal stability (noise), temperature compensation (the ability of the MAF sensor to measure airflow accurately from -30°C to 70°C) and electromagnetic compatibility.

Never remanufactured MAF sensor

Some things are better new. That’s why every sensor we make – whether with or without the housing—is built with all-new components and never remanufactured. Remanufactured MAFs are simply cleaned and tested, so any contamination on the sensor may not be eliminated, resulting in inaccurate readings to the ECU.

Greener probe-only technology

It’s often the electronics on the sensor probe that fail, meaning it’s not always necessary to replace the complete part. So we developed a probe-only solution, in addition to a full range of complete units. By eliminating the plastic housing, this provides a greener, more cost-effective and faster repair option.

The complete package

With Delphi you get access to the complete package: the range, advanced DS diagnostics including the ability to look at live data, both at idle and max RPM, to determine if the MAF sensor is reporting the correct data, expert training and support and vehicle technical information including wiring diagrams, component locations and guided diagnostic procedures.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we take a closer look at the Steering angle sensors, what it does, why you need to reset it and even what to look out for in a failing sensor.

Steering angle sensors (SAS) are nothing new. In fact, they’ve been around since the early 1990’s. With advances in Electronic Stability Control (ESC) systems, however, the need to reset them after routine maintenance has only recently become a necessity. Whilst this will add another step to most steering jobs, it also represents a potentially profitable service opportunities for garages in the know. Here we take a closer look at the SAS, what it does, why you need to reset it and even what to look out for in a failing sensor. So, you can be ready on your next steering job, to reset and go….

What is a steering angle sensor?

In the past decade or so, manufacturers have added a number of sensors to the vehicle’s steering system. One of these is the SAS, typically found in multiples inside the steering column. An integral part of the vehicle’s stability control system, it provides an accurate reading on the position of the wheels and rate of turn. It also works with the yaw, accelerometer and wheel speed sensors to measure the dynamics of the vehicle; what the vehicle is doing, what the driver wants the vehicle to do, and what corrections need to be made by the ABS hydraulic control unit to maintain control of the vehicle.

How do steering angle sensors work?

There are two main types of SAS; analogue and digital, the latter fitted to most modern vehicles. Analogue sensors are wired with a 5-volt reference, chassis ground and signal output. As the wheel is turned full circle, it produces a signal between 0 and 5 volts. The difference in voltage is used to determine the rate of turn and angle. Digital sensors, however, use a LED light to measure the rate of turn, the angle of the wheel, the direction of the turn and other important information.

Either way, if the SAS detects an inconsistency between the steering wheel’s position and the direction in which the vehicle is travelling, then the stability control system will kick in to help the driver maintain control of the vehicle. For example, if understeer occurs, it will automatically apply the rear brake on the inside of the vehicle to correct the problem.

Do steering sensors fail?

Whilst SAS are designed to last the lifetime of a vehicle, just like other electronic components, they are subject to wear and tear. They can also be damaged when working on other parts of the vehicle such as the power steering wheel. So, it pays to be familiar with the common symptoms of a faulty sensor just in case. Common signs to look out for include:

- Warning light comes on: when the SAS fails, it will trigger a stability system related warning light on the dashboard, indicating that the system has been disabled and requires servicing. On most cars this will be the traction control light but could also be the check engine light.

- Travel in the steering wheel: if a SAS is faulty or misaligned, it can send inaccurate information to the electronic control unit (ECU). This can cause the vehicle’s stability control system to provide incorrect steering adjustments, resulting in either a loose steering wheel, or the steering not responding in the way it should.

Why do you need to perform a steering angle sensor reset?

Since vehicles equipped with ESC, Advanced Driver Assistance Systems (ADAS) such as Lane Keep Assist (LKA) and Autonomous Emergency Braking (AEB), and other safety features, rely on accurate from the SAS, it is now necessary to reset them after performing a wheel alignment or replacing a component that can alter the toe and thrust angle. This will ensure these systems know exactly how the vehicle is traveling down the road in order to both predict, and make, the necessary safety corrections. If the SAS is out of calibration, and the angle is too far off, then the vehicle’s stability system will not function correctly, and ultimately will be disabled.

How do you reset the steering angle sensor?

Whilst the procedure to do this can differ significantly between manufacturers and models, there are several main methods of calibrating the SAS with the other sensors that make up these systems:

- Self-calibration: Some newer vehicles, can self-calibrate or auto calibrate by turning the steering wheel from lock to lock to centre and then cycling the key. Others will also have a set of commands that need to be performed for the calibration to initiate.

- Test drive: Newer vehicles with more advanced wheel speed sensors may automatically reset their own steering angle sensor the next time the vehicle is driven in a straight line for a set period. This is usually just a few seconds at motorway speed.

- Diagnostic scan tool reset: A scan tool reset may be required on some vehicles. Some alignment systems even have the SAS reset function built into it, eliminating the need for a separate diagnostic procedure after an alignment.

Most manufacturers recommend that steering angle sensor calibration is performed on the ground, versus a lift. When in doubt, always refer to the manufacturer's service manual for the correct procedure.

Just remember, whatever the vehicle, and whichever procedure they specify, steering angle reset should now be part of your standard alignment and your customer charged accordingly – providing yet another value-added service for independent garages.

Get in touch

The full Delphi Sensors product range

Find out where to buy Delphi parts