Resource Highlights

In this article you will find out about when to replace the steering and suspension bushings.

Bushings may seem small, but they play a big role in driver comfort and longevity of a vehicle’s steering and suspension system. A bushing acts as a cushion between parts and controls the amount of movement in the joints while reducing road noise, vibration and harshness. Steering and suspension bushings can deteriorate over time due to stress from constant movement, friction, heat and exposure to dirt and contaminants such as road salts and lubricants. Since a worn or damaged bushing will negatively impact these functions, it is important to inspect them regularly and replace whenever necessary.

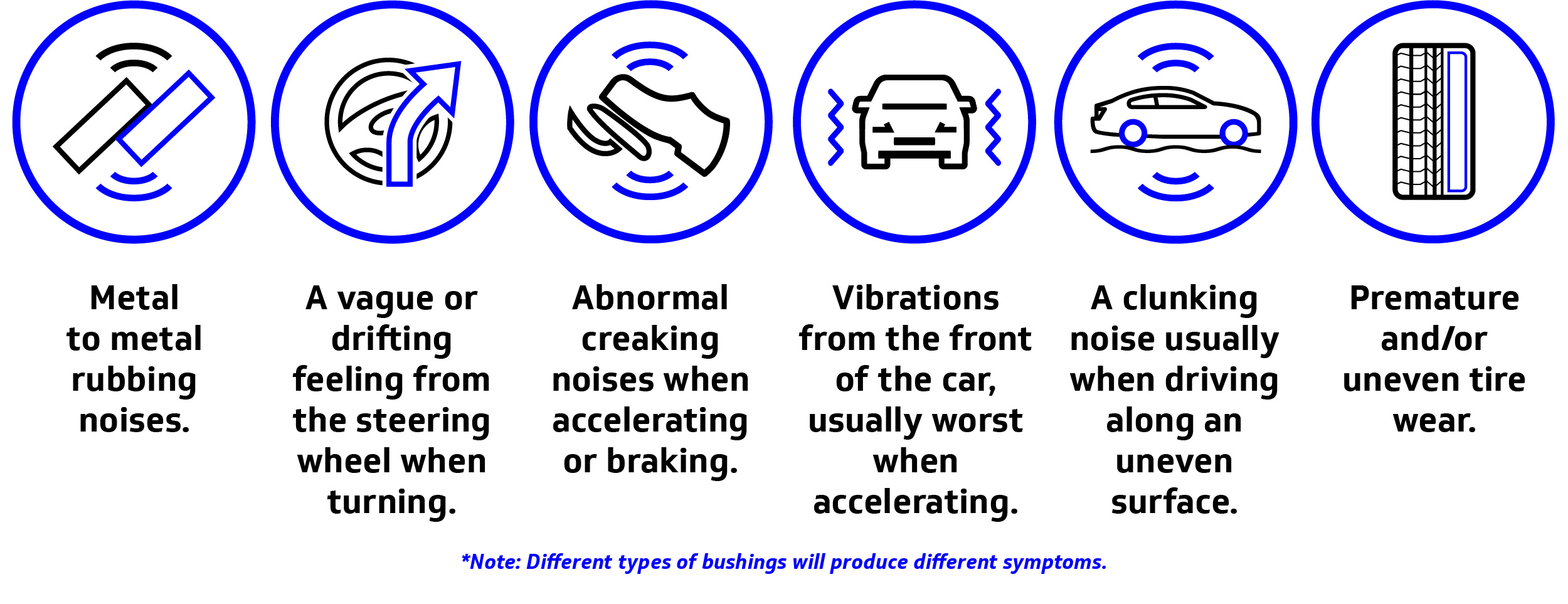

Signs of bushing wear

When bushings completely fail, metal-to-metal contact will occur between joints and connected parts, which will significantly decrease the life of the affected parts. Steering and suspension components can be expensive to replace, so it is important to install new bushings at the first sign of deterioration. A visual bushing inspection will show damaged or worn bushings, such as tears in the rubber or breaks in the rubber-to-metal bonding. Tire wear is also a good indicator of front and / or rear suspension issues. Outside of a visual inspection, other symptoms of worn or damaged bushings before complete failure include:

Tech tips for replacing bushings

When replacing a bush there are a few things to bear in mind:

- Use the correct bushing for the vehicle – although on the surface they may look the same, there are many internal features designed for the specific application.

- Replace sway bar bushings in pairs.

- Always carry out a dimensional check of the part before fitting.

- Remember to torque tighten the fixings with the vehicle on the ground before you take it for a test drive. Failure to do so could put unnecessary stress on the bushing in the wrong position, resulting in premature failure.

- Some bushings can be difficult to replace and may need specialized tools. In this case, it can be more economical to replace the entire component rather than just the bushing. For example, some control arm bushings cannot be replaced separately, so the control arm will have to be replaced entirely.

Choosing the right bushing replacement

For a vehicle suspension set up that is stiff and maximizes tire adhesion to the road, a hard rubber bushing with very little give is required. However, just like everything there’s a downside, and with improved handling comes the potential for more noise and less comfort. Alternatively, a soft bushing with a low shore hardness value will produce less noise, but could compromise the vehicle’s handling. Getting the right balance is therefore critical, and is why all Delphi bushings are engineered to provide the optimum shore hardness value, for both improved handling and noise and vibration reduction.

Interested in learning more about steering and suspension? Delphi is your full aftermarket service solution. We offer a Steering and Suspension 101 course for training technicians or as a refresher for more experienced technicians. Contact us today to learn more.