Delphi Technologies provides additional revenue opportunity for garages with new GDi test and cleaning capability

The latest generation machine enables the testing of both gasoline direct injection (GDi) and port fuel injection (PFi) systems, in as little as five minutes. Additional range of ultrasonic cleaning equipment allows garages to clean carbon deposits, a common service issue with GDi engines.

Together with OE parts, diagnostic tools and training, the full-service GDi solution opens-up a fast growing and profitable market opportunity for the independent aftermarket.

WARWICK, UK – Delphi Technologies Aftermarket is launching the production version of the Hartridge Excalibur GDi Master. Capable of testing both GDi and PFi, the compact desktop machine, which debuted as a prototype at Automechanika

Frankfurt 2018, is the latest addition to its GDi service program, alongside a range of ultrasonic cleaning equipment. Together with OE pumps, injectors and service kits for popular PSA applications, all makes electronic and hydro mechanical diagnostic

tools and training, the new capability provides workshops with another high-quality, cost-effective avenue into a growing and profitable gasoline fuel injection service market.

“More than 80% of light duty vehicles sold in 2030 are expected to have an internal combustion engine. Most of these will be gasoline, with a growing number of these GDi,” explains Adam Lee, Business Unit Director - Hartridge, Delphi Technologies Aftermarket. “We expect the overall GDi market will grow by over 30 percent in Europe over the next five to10 years, presenting an exciting opportunity for those workshops equipped with the right tools and know-how to service these vehicles. With the addition of test and cleaning capability to our GDi program, distributors, factors and garages will now be able to offer their customers a full, end-to-end service solution, creating value, loyalty and, most importantly, profitability, in what is one of the fastest growing areas of vehicle repair.”

Testing of both GDi and PFi systems in as little as five minutes

The Hartridge Excalibur GDi Master, one of a number of new generation all makes test solutions, provides workshops with the ability to diagnose GDi, both coil and piezo variants up to 235bar, as well as PFi injector technology. Using the same award winning, patented platform and magmahTouch software as the Sabre CRi series and the Toledo HEUi Master, the plug and play machine enables comprehensive testing in as little as five minutes.

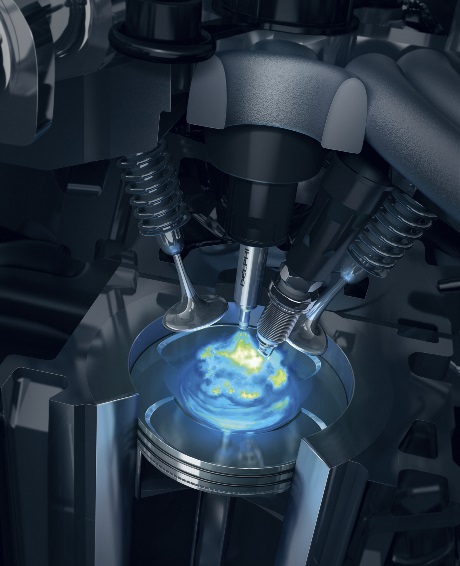

Featuring full event response time (FERT) technology, the Excalibur GDi Master can test for correct fuel delivery and injection timing, two critical parameters for GDi technology. The machine also includes integrated back-flush functionality to purge the injector of contaminants before testing, a unique spray pattern analysis module to determine if the spray profile/pattern from the nozzle is correct and a comprehensive library of automated and validated Hartridge test plans, making the whole package fast and easy to use.

Ultrasonic cleaning equipment allows garages to clean carbon deposits

As GDi injectors are located inside the engine combustion chamber, they are prone to high carbon build-up. To address this increasingly common service issue, Hartridge also offers a range of stainless steel, ultrasonic cleaning tanks. With cleaning cycles between one to three minutes they can shift stubborn carbon deposits quickly, ensuring a more thorough and faster clean than other methods.

“Customers increasingly expect their car to perform just like the day they bought it,” adds Lee. “The reality is that carbon build-up can occur almost immediately, and overtime will result in reduced torque, power and fuel economy. Regular cleaning, using one of our tanks, can help restore injectors to as good as new, optimizing the vehicle’s performance and fuel economy.”

The Hartridge Excalibur GDi Master and ultrasonic cleaning equipment are the latest additions to the company’s GDi service program. Launched in late 2018, the comprehensive program consists of pumps, injectors and service kits fitted as OE to more than 2.1 million popular PSA vehicles, with other important applications planned for later this year. It also includes electronic and hydro-mechanical diagnostic tooling and training, offering broader all makes GDi capability.

For more on Delphi Technologies’ GDi service program visit hartridge.com.

Downloads