Resource Highlights

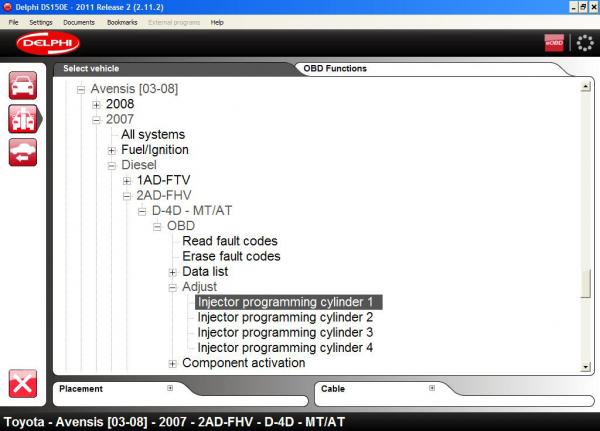

In this article you will find out about the step-by-step guidance on injector programming for Toyota D-4D engines.

Vehicle Applications

Engine | Models | Systems |

| Toyota | 1AD-FTV (2L) / 1KD-FTV (3L) / 2AD-FHT (2.2L)/ 2AD-FTV (2.2L)/2KD-FTV (2.4L) | Diesel Systems |

Summary

The correction code printed on each injector must be programmed into the engine DCU every time one or more injectors are replaced.

When to Program

This operation must be carried out if:

- One or more injectors have been replaced.

- The DCU has been replaced (a new DCU must always be reprogrammed with the codes for all the injectors).

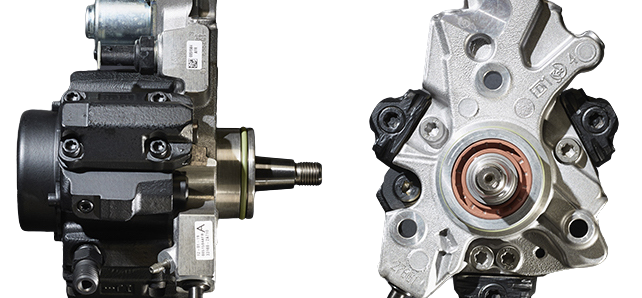

Note: Every injector has its own individual correction code. The code has 30 characters printed on top of the injector. If the correction code programmed in the engine DCU is incorrect for the injector, the engine may stall and run very badly at idle. The engine may also break down and have a reduced service life.

STEP BY STEP

Test Preconditions

- Battery voltage is greater than 12 V.

- Immobilizer switch on run, engine stopped.

- No-fault codes in memory.

Procedure

1. Select the function: "Injector programming 1, 2, 3 or 4"

2. A dialogue box will be displayed to confirm the code programmed for the injector.

3. Confirm with "OK" to reprogram the injector code.

- If the code is correct, choose "OK".

- To quit the program choose "Abort".

4. Enter the 30 characters of the code printed on the injector (see illustration), then click "OK" to validate.

5. A dialogue box will be displayed to confirm the code chosen; click "Yes" if it is correct.

- Click "No" to stop the programming process.

6. If the programming process has been successful, the old and new codes will be displayed.

7. Confirm with "OK" to finish the process.

8. Check and delete any fault codes.

Caution

If the process has failed, check the fault codes and check that the correct code entered is correct. Even if the correct code is correct and no other fault code is present, the DCU may still not function correctly. Check the engine DCU and restart the operation from the beginning.