Featured News

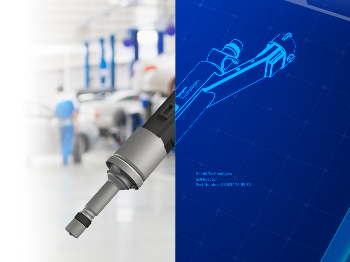

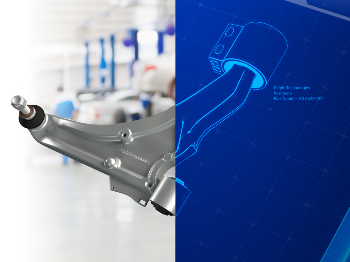

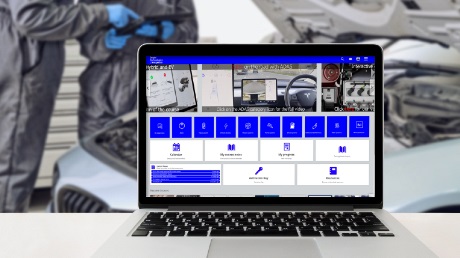

Delphi Releases Nearly 500 Parts in 2023 and Announces Training Opportunities at AAPEX 2023

Delphi will attend the 2023 Automotive Aftermarket Product Expo (AAPEX) at the Venetian Expo in Las Vegas, Nevada, from October 31st through November 2nd at booth A5027.

Delphi Releases Nearly 500 Parts in 2023 and Announces Training Opportunities at AAPEX 2023: Read more"Delphi Releases Nearly 500 Parts in 2023 and Announces Training Opportunities at AAPEX 2023"