Resource Highlights

In this article you will find out about brake fade.

Look up ‘fade’ in the dictionary and it says ‘to gradually grow faint or disappear’ – not something you’d expect to hear in the same sentence as a safety critical component such as brakes. However, brake fade is an issue. And although more commonly associated with street or track racing, it can happen to regular cars too, especially when braking from higher speeds or under load. Because of this, it’s important to understand what causes it, and importantly, what you and your customers can do to prevent it.

What is brake fade?

Brake fade is a temporary and sudden reduction in braking power, caused by excessive heat in the system from braking repeatedly, under high loads or at high speeds. Unlike brake failure caused by a mechanical or hydraulic fault, the system is normally in good working order, and brake power will return, albeit not necessarily to the same level, once the issue has been addressed.

What causes brake fade?

In simple terms, brakes function by converting kinetic energy into heat. Every time the brakes are applied the system will generate heat, which under normal driving conditions, will dissipate into the atmosphere and other components once released. However, since kinetic energy rises with the square of velocity, braking from higher speeds or under load puts an exponentially increased demand on the system, generating significantly more heat. This excessive heat can quickly build up in the system, which if not dispelled effectively, can result in brake fade.

Types of brake fade:

Before we look at ways to prevent fade, it’s important to understand that there are different types of brake fade:

Brake pad fade:

Every brake pad has a maximum temperature range. When operating outside of these parameter’s, the frictional material effectively starts to degrade, causing the resins that bind the pad compounds together to out-gas, and in turn, creating a thin layer of high-temperature gas between the pad and disc. This new film causes the pad to essentially skid off the disc, temporarily reducing pad to disc friction coefficient and therefore braking power.

At these higher temperatures, the brake pads can also transfer a thin, uneven layer of friction material onto the surface of the disc. As the pads rub on the now uneven brake disc surface, they can create irregular heat build-up across the disc. If the temperature in these areas exceeds 650°C, the cast iron changes structurally and transforms into a hard material called cementite, creating high spots which can lead to brake judder and premature disc wear.

Green or early life brake fade:

New brake pads release gases the first few times they reach high temperature, and just like pad fade, create a loss of friction, known as green or early life fade. The good news is that green fade can easily be avoided by bringing the pads up to high temperatures under controlled conditions – a process known as bedding in the pads. This allows the two mating surfaces to transfer a layer of friction material to each other – pad to disc and disc to pad – in order to seat together and deliver optimal braking performance from new. Unlike pad fade, this even friction material transfer is beneficial after new pads have been installed.

Brake fluid fade:

For brakes to operate correctly and the brake pedal to remain solid, brake fluid must remain incompressible. However, if the fluid boils from prolonged or heavy braking, any moisture in it will also boil and turn to vapour. Since vapour is easier to compress than liquid, the brake pedal will eventually travel all the way to the floor, resulting in reduced, or even no braking power – pumping the brake pedal in this situation will help to regain some of it. To make matters worse, over time brake fluid absorbs water – as the moisture content of the fluid increases, the point at which it boils decreases, making the risk of brake fluid fade greater. If your customer has experienced fluid brake fade you’ll need to bleed flush through the brake fluid from the calipers until you get clear brake fluid.

Preventing brake fade:

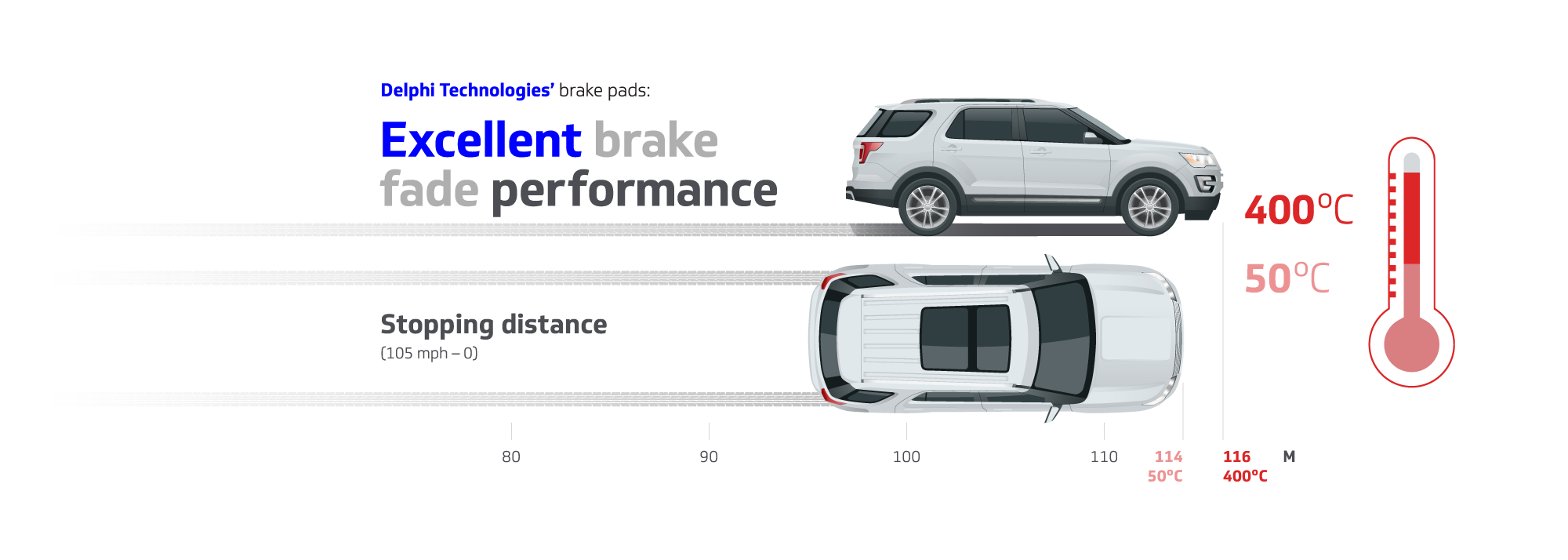

For high performance or loaded vehicles, fitting components that are engineered to handle the additional braking demand is critical. Take our brake pads as an example. With a choice of more than 130 different friction ingredients, the friction material is especially formulated for the vehicle it is designed to fit. And our brake discs feature proven cooling technologies such as directional vents and cross drilled holes to improve both their cooling capacity and resistance to thermal shock.

Likewise, technicians should always perform a full road test in a safe environment to properly bed in the pads and discs, with 10 repeated stops at 60 percent braking effort, from 60mph to 20mph. During this procedure try to avoid heavy 100 percent braking or activating the ABS, and never leave your foot on the brake pedal to avoid stopping fully.

There are also some simple measures that your customers can take to minimise the risk of brake fade…and at the same time save fuel and reduce wear and tear:

- Avoid riding the brakes as repeated use can easily overheat the system.

- Where possible, avoid heavy braking.

- Slow down – the faster you drive the more work your brakes will have to do.

- Anticipate the need to slow down by thinking ahead.

- Lighten the load in your car – more weight means the brakes have to do more work to stop your vehicle.

- On downhill descents, especially if towing, change into a lower gear and make use of engine braking instead. If this is not enough, pull over and let the brakes cool down.

- Replace brake fluid as per the vehicle manufacturer’s recommendation to reduce the risk of degradation.

- Remember to bed in your pads if your garage hasn’t already done this

Offering simple advice like this, is a great way to demonstrate your new-found technical expertise and build lasting relationships with your customers, that like Delphi brakes, will never fade. Learn more about our brake pads.

SIGN UP TO FIND MORE

Fill up your details to hear more from our experts and get the latest updates from Delphi.