Balancing Precision and Environmental Impact

Independent testing is vital in the automotive world. It's the cornerstone of credible automotive research and development. It eliminates potential biases that may arise when tests are conducted internally by manufacturers. Independent testers have no stake in the outcome, ensuring that the results are objective and that the best interests of consumers and the environment are kept at the forefront.

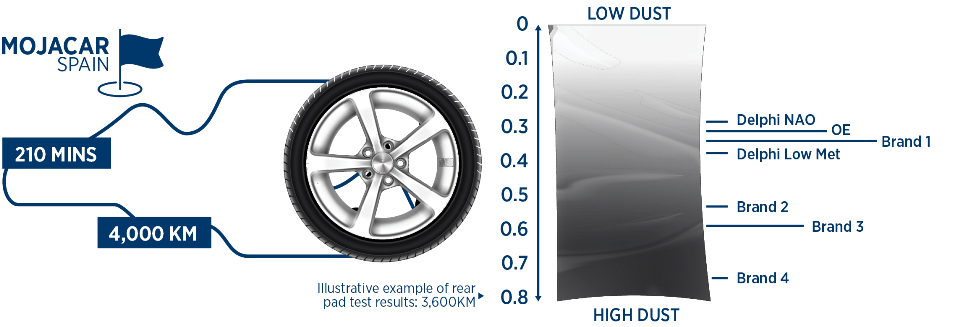

In the sunny and consistent climate of Mojacar, Spain, Delphi's latest brake pads recently underwent rigorous testing by an independent company. The conditions were ideal: over 3,180 hours of sunshine each year and very little rainfall to affect the results. Here, Delphi's brake pads were put to the test against other premium brands. The goal was clear: to see which pads could deliver not just in performance but also in environmental responsibility.

The results are in, and they tell a compelling story. Delphi's brake pads not only met the high standards set for the tests but also often exceeded them, standing out among competitors. These results are a testament to the quality and reliability of Delphi's braking systems, solidifying our reputation in the market as leaders in automotive brake technology.

Objective Testing for Optimal Braking

An independent testing company selected four Mercedes A-class vehicles as test subjects, fitting them with premium brake discs and pads. This wasn't a showcase of random assortments but a battle among titans, with six top-tier brands, including Delphi's NAO and low metallic pads, and the OE products, going head-to-head.

Clean Brakes for a Clean Environment

For the dust test, vehicles cruised 4,000 kilometres on dry roads, avoiding any interference from rain or surface water. This consistency was key to ensuring that the dust collected was solely from the brake pads.

The vehicles, driven in a convoy, took on a 200km circuit that combined the challenges of mountainous and urban driving, each loop taking 210 minutes to complete. Over ten days, each car completed two circuits daily, ensuring a thorough and exhaustive test of the brake pads' dust emissions.

Delphi's NAO pad emerged superior, surpassing other premium brands and the OE in dust emission tests. Less brake dust means less wear on the brakes and, importantly, fewer particles released.

Delphi low metallic (low met) pads also outperformed. In comparison to some premium brands, Delphi's low met pads produced half the amount of dust, placing them at the forefront in terms of efficiency.

Brake dust is more than just an aesthetic concern for vehicle owners; it's a significant environmental issue. As brake pads wear down, they release particulate matter into the air. This dust can affect air quality and has been a focus of environmental regulations. This result also translates to cost savings for consumers while reducing the volume of waste and the need for manufacturing new components.

Moreover, fewer particles in the air mean a lower impact on public health and the environment, as brake dust has been linked to respiratory issues and other health concerns.

Quiet Brakes for Maximum Comfort

In the noise test, Delphi pads achieved top marks for quiet operation, scoring a 9.8 noise index, where 10 symbolises complete silence. This result surpassed the performance of both IAM and OE competitors.

The low noise levels mean reduced sound pollution, contributing to a quieter life inside and outside the vehicle. For drivers, it translates to a more relaxed driving environment, lessening the auditory stress that often accompanies extended road travel.

It's not just humans who suffer from noise pollution either; wildlife is also impacted, with evidence showing that noise pollution can lead to physiological stress in caterpillars and disruptions in the behaviour and well-being of marine mammals. It interferes with animals' ability to navigate, find food, mate, and avoid predators, impacting their survival.

Consistency Equals Safety

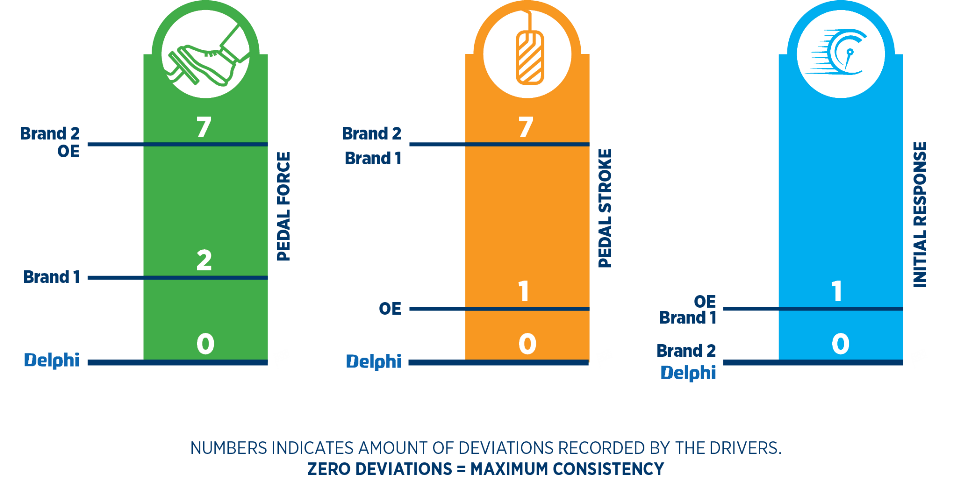

The brake pedal is the driver's direct line to the vehicle's stopping power. When a driver presses the pedal, a certain response is expected: the vehicle should decelerate at a predictable rate.

Consistency in this response is crucial. It means that no matter the situation—whether you're stopping for a red light on a sunny day or braking suddenly to avoid an obstacle—the feel of the pedal underfoot remains the same, predictable and reliable.

Delphi's brake pads were put to the test by independent professional drivers skilled in detecting even the slightest variation in brake pedal feel. Compared to competitors, Delphi had the most consistent results. Achieving zero deviation is significant — it indicates that every time the brake pedal was engaged, it felt exactly the same to the driver. There were no surprises, no changes in resistance, and no delays in response.

This consistency is a cornerstone of driver safety, as it allows drivers to build muscle memory and an intuitive understanding of their vehicle's braking behaviour.

Forward-Thinking Results

The tests in Mojacar offer a glimpse into the future of automotive safety and environmental responsibility. With meticulous planning and execution, the results showcase Delphi's braking products as a benchmark for quality and sustainability.

Downloads