Ball Joints

- Manufactured to OE standards for control, comfort and durability

- Ball-pin 100% crack tested for flaw free material

- Undergo rigorous performance and resilience tests

- Chloroprene rubber cover protects internal components

- Superior ball-pin finish and nylon seat coating for smooth movement and long lifetime

- High specification grease for reduced friction, and smooth operation in all temperatures and conditions

- Cataphoretic coating where required provides longer lasting corrosion protection

- Access to technical hotline and support

- Three-year/36,000-mile warranty on all steering parts – available in UK only

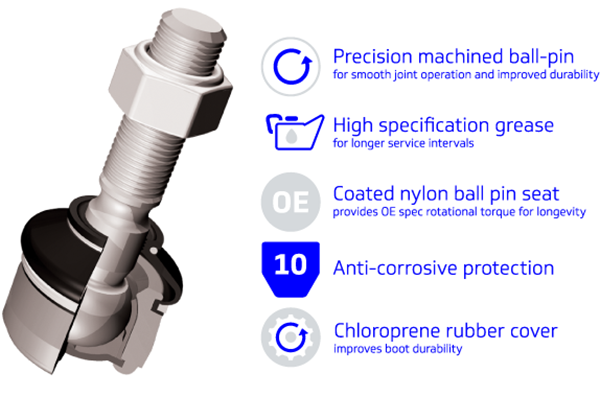

Precision engineering

Enabling free movement in two planes at the same time, the ball-pin is a critical component. That’s why our ball-pins are manufactured from high-grade steel and machined to micron tolerances. Together with a polyoxymethylene nylon ball-pin seat, they provide optimum durability and smooth joint operation.

Extensive testing

Delphi ball joints undergo rigorous performance tests including angular stress testing, where the ball is rotated through its angular and rotational travel under load, as well as a pull and push out test, to measure the force required for it to break away from the housing. These important safety tests ensure the ball joint can withstand the same forces as the OE part.

Longer service intervals

We provide a range of sealed ball joints, that are lubed for life with a high-specification grease, to minimise maintenance requirements. Alongside our precision ball-pin finish and improved rubber boot design, they offer longer ball joint service intervals and better grease retention.

Greater protection

To help prevent damage to the joint’s internal components, all our ball joints come with a special chloroprene rubber cover. The new and improved formula maintains its durability even in extreme temperatures, providing added protection from road dirt or salt and allowing continued free movement of the ball joint for a longer lasting part.

.jpg?sfvrsn=d5e08686_1)

Three-year warranty – available in UK

As a guarantee of our OE-quality standards, we offer a three-year or 36,000-mile warranty on all our ball joints. So, you can fit Delphi steering parts with complete confidence.

Cataphoretic coating

Like many of our steering parts, Delphi ball joints feature an environmentally friendly cataphoretic coating for tougher and longer lasting protection from corrosion caused by salt, dirt and water and other contaminants.

Tech Tip

Delphi is advising technicians to help ensure a quality steering and suspension repair by replacing the entire ball joint component where the rubber boot is split, cracked, damaged or missing. In these instances, there is a high probability that damage to the ball joint may have occurred, indicating the joint is likely to fail even after the boot cover has been replaced. Replacing the entire ball joint component can help avoid potential premature failure, which can be safety-critical and costly.

.jpg?sfvrsn=43ce0fa5_0)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we discuss our aluminum steering and suspension products. he at Delphi, we offers a comprehensive range of popular aluminum steering and suspension products, as well as a range of kits for Audi and VW applications.

A comprehensive range of popular aluminum products

Because aluminum steering & suspension parts are lighter than traditional steering parts, they help improve fuel economy and consumption efficiency. This is making them increasingly popular on vehicles today. Delphi offers a comprehensive range of popular aluminum steering and suspension products, as well as a range of kits for Audi and VW applications.

Delphi kits have many customer advantages which include:

- A complete range for all makes

- Include necessary accessories for a complete and safer repair

- Cost effective through reduced fitting times

- Minimized inventory space required

- Parts can be sold individually or as a kit

Designed and tested for reliability

Steering and suspension systems are safety critical parts, and also have a direct impact on ride comfort. Delphi steering and suspension parts are developed to ensure durability and high performance levels. High quality and well-fitted steering and suspension parts are essential for vehicle safety, performance and ride comfort.

Delphi steering and suspension parts are subjected to rigorous tests, such as durability load, salt spray, vibration and computer controlled simulation tests. Delphi OE standards include a comprehensive product development process with our quality matching the OE product in terms of aesthetics and performance.

All Delphi steering parts are application engineered against OE product, helping to ensure a match to the original parts in terms of content, fit, form and function. All parts are manufactured to exacting OE dimensional and material specifications confirming they are within the correct tolerances.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Steering & Suspension product range

Find out where to buy Delphi parts