Ball Joints

- Manufactured to OE standards for control, comfort and durability

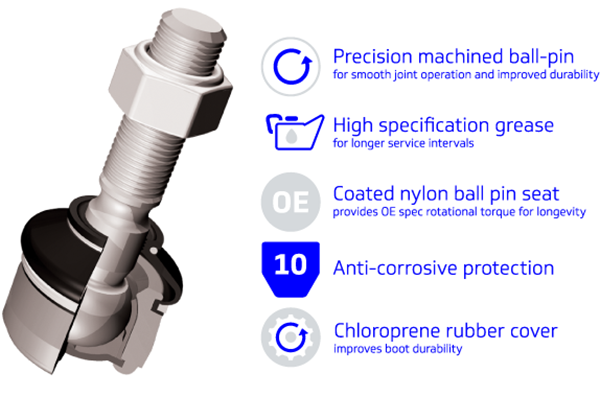

- Ball-pin 100% crack tested for flaw free material

- Undergo rigorous performance and resilience tests

- Chloroprene rubber cover protects internal components

- Superior ball-pin finish and nylon seat coating for smooth movement and long lifetime

- High specification grease for reduced friction, and smooth operation in all temperatures and conditions

- Cataphoretic coating where required provides longer lasting corrosion protection

- Access to technical hotline and support

- Three-year/36,000-mile warranty on all steering parts – available in UK only

Precision engineering

Enabling free movement in two planes at the same time, the ball-pin is a critical component. That’s why our ball-pins are manufactured from high-grade steel and machined to micron tolerances. Together with a polyoxymethylene nylon ball-pin seat, they provide optimum durability and smooth joint operation.

Extensive testing

Delphi ball joints undergo rigorous performance tests including angular stress testing, where the ball is rotated through its angular and rotational travel under load, as well as a pull and push out test, to measure the force required for it to break away from the housing. These important safety tests ensure the ball joint can withstand the same forces as the OE part.

Longer service intervals

We provide a range of sealed ball joints, that are lubed for life with a high-specification grease, to minimise maintenance requirements. Alongside our precision ball-pin finish and improved rubber boot design, they offer longer ball joint service intervals and better grease retention.

Greater protection

To help prevent damage to the joint’s internal components, all our ball joints come with a special chloroprene rubber cover. The new and improved formula maintains its durability even in extreme temperatures, providing added protection from road dirt or salt and allowing continued free movement of the ball joint for a longer lasting part.

.jpg?sfvrsn=d5e08686_1)

Three-year warranty – available in UK

As a guarantee of our OE-quality standards, we offer a three-year or 36,000-mile warranty on all our ball joints. So, you can fit Delphi steering parts with complete confidence.

Cataphoretic coating

Like many of our steering parts, Delphi ball joints feature an environmentally friendly cataphoretic coating for tougher and longer lasting protection from corrosion caused by salt, dirt and water and other contaminants.

Tech Tip

Delphi is advising technicians to help ensure a quality steering and suspension repair by replacing the entire ball joint component where the rubber boot is split, cracked, damaged or missing. In these instances, there is a high probability that damage to the ball joint may have occurred, indicating the joint is likely to fail even after the boot cover has been replaced. Replacing the entire ball joint component can help avoid potential premature failure, which can be safety-critical and costly.

.jpg?sfvrsn=43ce0fa5_0)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Steering you down the right way! Common symptoms, causes and fixes for best practice steering repairs

Resource Highlights

In this article, you will find out about the common symptoms, causes and fixes for best practice steering repairs.

A vehicle's steering and suspension system is an intricate network of components designed to ensure a smooth, stable and safe ride. It is also subject to significant road abuse, and as such, key parts are often prone to wear and damage. So if your customer reports that their car doesn't seem to ride like it used to, then they may have a steering or suspension issue.

However, the key word here is ‘may’. So before you start replacing parts, it's a good idea to check both the steering system, as well as all other associated components. After all, the issue could be caused by something as simple as low tyre pressure, simpler still, a loose nut, and can be easily and cheaply fixed. Here we provide a list of the common symptoms and possible causes to help you narrow your diagnosis and repair options, saving you and your customer time and money.

Symptom: Pulling to one side while driving.

The vehicle tends to pull to one side or the other. The wheel needs to be held firmly to keep the vehicle straight.

- Low or uneven tyre pressure > check tyre inflation.

- One or more wheels out of balance > balance wheels.

- Uneven or excessive tyre wear > inspect tyres, replace in pairs and check wheel alignment.

- Worn steering components > inspect tie rods and steering rack for excessive play and repair if needed.

Symptom: Loose or sloppy steering

Steering has excessive play and wanders from side to side.

- Worn strut bearings > inspect strut bearings for play and replace in pairs.

- Worn or broken tie rods or steering rack > inspect steering components and replace as necessary.

- Worn ball joints > inspect ball joints and replace if needed.

- Broken steering rack mounts > inspect steering rack mounts and repair or replace (some cars can be fixed, others require replacement of the entire steering rack.)

- Loose steering components > tighten all components to recommended torque.

Symptom: Hard steering.

The steering wheel becomes harder to turn, especially at slower speeds.

- Low tyre pressure > check tyre inflation.

- Poor wheel alignment > check and adjust wheel alignment.

- Power steering fluid low > check power steering fluid and add if needed. Inspect power steering lines for any leaks and repair if required.

- Contaminated power steering fluid > flush and refill the system with fresh fluid.

- Worn or damaged power steering belt > inspect power steering belt and replace where necessary.

- Faulty power steering box, rack or pump > inspect and adjust/replace relevant components.

- Worn or damaged steering gear > lubricate and repair if needed.

Symptom: Vehicle wanders.

The direction of the car needs to be constantly adjusted.

- Poor wheel alignment > check and adjust wheel alignment.

- Severely worn or out of spec front wheel bearings > replace or adjust bearing.

- Worn ball joints > inspect ball joints for play and replace if needed.

- Loose steering components > tighten all components to recommended torque.

- Vehicle is overloaded or weight distributed unevenly > adjust load accordingly.

- Damaged steering component > replace as appropriate.

Symptom: Clunking over bumps or turning.

Feeling clunks and knocks through the steering wheel when you go over bumps or even cracks in the road.

- Worn ball joints > inspect ball joints for play and replace if needed.

- Worn or damaged steering gear > check steering gear, lubricate and replace where necessary.

- Loose steering components > tighten all components to recommended torque.

- Something rubbing against or knocking steering column > review and adjust accordingly.

- Tyres rubbing against or knocking something > review and adjust accordingly.

- Broken suspension spring > replace spring.

Symptom: Noises from the power steering unit.

Whining or moaning sound when steering wheel is turned all the way in one direction.

- Power steering fluid low > check power steering fluid and add if needed. Inspect power steering lines for any leaks and repair if required.

- Air trapped in power steering fluid > flush and bleed the power steering system of air.

- Damaged or loose power steering drive belt > adjust or replace as necessary.

- Damaged or loose mount for power steering pump > adjust or replace as necessary.

Symptom: Vibrating steering wheel.

Excessive vibration through the steering wheel.

- Warped or damaged discs or drums > service and/or replace discs or drums.

- Worn ball joints > inspect ball joints for play and replace if needed.

- One or more wheels out of balance > balance wheels.

- Severely worn or damaged tyres > inspect tyres and replace in pairs.

- Damaged wheels > inspect wheels and replace as needed.

- Loose steering components and/or wheel nuts > tighten all components to recommended torque.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Steering & Suspension product range

Find out where to buy Delphi parts