Heavy duty & off-highway Diesel Fuel Injection

Rich OE legacy

Our heritage dates back to the legendary CAV brand, and the introduction of in-line and the iconic DPA pump – the best-selling rotary pump worldwide. Both were revolutionary for their time, setting new standards for reliability and power, and we’ve continued to push the boundaries ever since.

Three choices for fleets

By providing three choices – new, reman and repair – we can provide fleet managers with convenient service and maintenance at a very competitive cost.

Latest generation OE technology

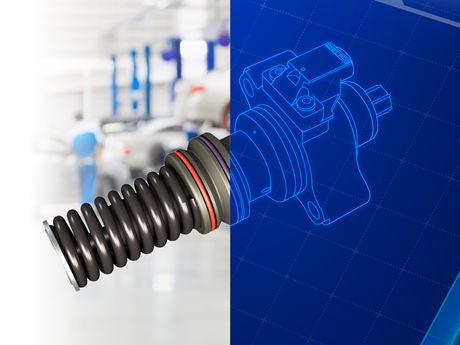

Our latest generation F3 system takes engines beyond the 2021 global emissions and fuel economy regulations and through the next decade. Based on our proven Euro VI Common Rail technology and capable of 3,000 bar injection pressure, it delivers a substantial improvement in emissions, fuel economy and refinement for the lifetime of the engine.

OE-approved repair

In addition to new and remanufactured units, we also offer authorised repair through our global network of Delphi Diesel Centres. Replacing all wearable and performance critical parts, with like-for-like OE, and using OE-approved test plans and equipment, it offers a quality but economical solution.

Find your local diesel specialist here.

Reman

For an equally fast, yet more cost-effective turnaround we offer a range of remanufactured parts. Available off-the-shelf, typically within one to two years of vehicle launch, they are built using OE parts, equipment and processes, and are calibrated to exacting OE specifications.

OE expertise in the aftermarket

Of course, we’re committed to supporting these technologies in the aftermarket. We offer a range of new OE components, identical to those originally fitted, including our pioneering Electronic Unit Injector, Electronic Unit Pump, Smart injector and Multec® Common Rail.

Commercial vehicle diagnostics and test

Our dedicated diagnostic solution for trucks, buses and trailers, supports the key commercial vehicle manufacturers and systems, including the ability to carry out dosing tests, Adblue freeze monitoring calibration, system drain down and regeneration of the SCR system. We also offer a range of OE-approved test equipment for quick and accurate test and repair of the latest heavy duty applications.

Training from the OE experts

Designed to help you prepare for the very latest heavy duty diesel fuel injection technologies, our extensive training programme covers the repair of key systems, including Electronic Unit Injector and Pump and Smart injectors. Learn more about our training.

.jpg?sfvrsn=950636e0_7)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

How to Deal with Blocked Fuel Filters on Common Rail Applications

Resource Highlights

In this article you will find out about how to deal with Blocked Fuel Filters on Common Rail Applications.

Make | Model | System |

Renault | Common Rail Systems | Diesel Systems |

Ford | Common Rail Systems | Diesel Systems |

Mercedes | Common Rail Systems | Diesel Systems |

Citroen | Common Rail Systems | Diesel Systems |

Peugeot | Common Rail Systems | Diesel Systems |

Jaguar | Common Rail Systems | Diesel Systems |

Suzuki | Common Rail Systems | Diesel Systems |

VW | Common Rail Systems | Diesel Systems |

Nissan | Common Rail Systems | Diesel Systems |

Kia | Common Rail Systems | Diesel Systems |

Hyundai | Common Rail Systems | Diesel Systems |

Ssangyong | Common Rail Systems | Diesel Systems |

Confirmation of the Fault | Common Rail systems demand a high level of filtration to ensure longevity of the system components. In many cases the fuel filter is ignored as more complex items are interrogated to source the root cause in a fault code creation situation. In view of the level of filtration required by the common rail systems, blockage may cause intermittent faults to be noted. If a lack of power is noted under heavy load (high engine speed and heavy acceleration) and faults with the pressure sensor or pressure control are noted, it may be useful to center the diagnostic investigation on the filtration circuit (Refer to the diagnostic manuals for the applications concerned to identify the fault codes). When the filter begins to block up, if there is a high volume fuel demand, the fuel flow is throttled. The amount of fuel provided by the pump is then insufficient, causing a temporary drop in pressure. Pressure control is a contributory factor to limp home or even engine stall situations. |

Resolution | The fuel supply circuit must be inspected (restriction in the circuit, air leak, fuel leaks). Then, the vacuum / pressure between the filter and the pump must be measured using a pressure gauge. This operation must be carried out with the greatest care and cleanliness possible to avoid the ingress of contamination into the system. If the engine fails to start than a mitivac can be used to determine any flow restrictions between the fuel filter and high pressure pump inlet. On vehicles with a low pressure feed pump a positive pressure must exist between filter and high pressure pump. If not, the operation and security of the filter, pipe work and feed pump must be checked. By using a pressure gauge in between the filter and fuel high pressure pump, you can determine if the pressure feed remains positive while running the engine. If the pressure reading becomes negative the filter should be replaced and the system retested. Low pressure systems run typically at 0.5 bar, but the key is that the feed pressure remains positive in all cases. On non-low pressure pumped systems where the engine does run at idle speed, the vacuum should not exceed a value of 200 to 300 mbar between filter and high pressure pump. Values higher than this indicate a system restriction, usually the fuel filter being clogged. |

Service Policy | It is recommended that the Original Equipment filter is fitted on all common rail systems to maintain the security of the hydraulic system. |

Get in touch

Find out where to buy Delphi parts