Heavy duty & off-highway Diesel Fuel Injection

Rich OE legacy

Our heritage dates back to the legendary CAV brand, and the introduction of in-line and the iconic DPA pump – the best-selling rotary pump worldwide. Both were revolutionary for their time, setting new standards for reliability and power, and we’ve continued to push the boundaries ever since.

Three choices for fleets

By providing three choices – new, reman and repair – we can provide fleet managers with convenient service and maintenance at a very competitive cost.

Latest generation OE technology

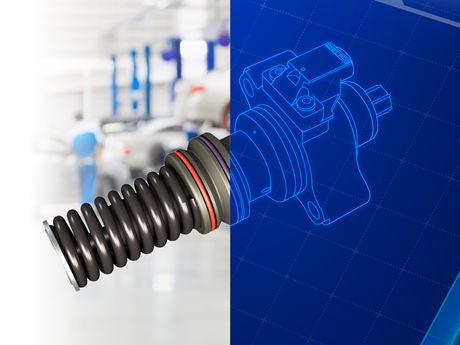

Our latest generation F3 system takes engines beyond the 2021 global emissions and fuel economy regulations and through the next decade. Based on our proven Euro VI Common Rail technology and capable of 3,000 bar injection pressure, it delivers a substantial improvement in emissions, fuel economy and refinement for the lifetime of the engine.

OE-approved repair

In addition to new and remanufactured units, we also offer authorised repair through our global network of Delphi Diesel Centres. Replacing all wearable and performance critical parts, with like-for-like OE, and using OE-approved test plans and equipment, it offers a quality but economical solution.

Find your local diesel specialist here.

Reman

For an equally fast, yet more cost-effective turnaround we offer a range of remanufactured parts. Available off-the-shelf, typically within one to two years of vehicle launch, they are built using OE parts, equipment and processes, and are calibrated to exacting OE specifications.

OE expertise in the aftermarket

Of course, we’re committed to supporting these technologies in the aftermarket. We offer a range of new OE components, identical to those originally fitted, including our pioneering Electronic Unit Injector, Electronic Unit Pump, Smart injector and Multec® Common Rail.

Commercial vehicle diagnostics and test

Our dedicated diagnostic solution for trucks, buses and trailers, supports the key commercial vehicle manufacturers and systems, including the ability to carry out dosing tests, Adblue freeze monitoring calibration, system drain down and regeneration of the SCR system. We also offer a range of OE-approved test equipment for quick and accurate test and repair of the latest heavy duty applications.

Training from the OE experts

Designed to help you prepare for the very latest heavy duty diesel fuel injection technologies, our extensive training programme covers the repair of key systems, including Electronic Unit Injector and Pump and Smart injectors. Learn more about our training.

.jpg?sfvrsn=950636e0_7)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

How do I remove the DPF sensor?

Firstly, you’ll need to remove the engine cover. Next, remove the electrical connector from the sensor by putting pressure on the connector and press it in. Now lift the tab and you should be able remove it with a pull. Lastly, you’ll need to remove the pipework from the sensor before you take it out.

How do I remove the pipework?

Unscrew the retaining screw from the sensor. Once you’ve done this you can start work on unfixing the pipework. Using a pair of pliers, loosen the clips from the pipework. Now, slide the pipework off the sensor.

How do I visually inspect the new part?

Simply put the old and new parts next to each other and check that the barbs are the same diameter and the electrical keyways are the same.

How do I fit the new part?

Essentially, do what you’ve just done in reverse. When it comes to fitting the clips to the pipework, use the pliers again making sure the clips are snug and not too close to the edge. Relocate the sensor into the clip, place it against the backing plate and put the retaining screw back in. Now, reattach the electrical connector, pushing down firmly until you hear a click that lets you know it’s secure. Replace the engine cover and use a diagnostic tool to erase any fault codes and check live data.

Get in touch

Find out where to buy Delphi parts