Cabin Air Filters

High-performance media

All our cabin air filters use a high-performance, non-woven fabric to eliminate dust, pollen, bacteria and exhaust particles, amongst others. The specially designed filter fabric contains up to five individual layers, removing near 100 percent of harmful pollutants.

Enhanced protection

Over time moisture can build up in the filter and become a feeding ground for bacteria and mould. This can then spread into the lines of the HVAC system, where it emits unpleasant odours. For the ultimate protection from this and other pollutants, we also offer a range of carbon activated filters. Our carbon activated filters feature the same high quality, non-woven fabric as our particle filters, with the addition of a layer of activated carbon. Sandwiched between two layers of fleece, this highly effective technology removes more pollutants than standard filters, and expels nasty gases and smells too.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, you will find some of our air conditioning repair recommendations.

Equipment Checks

Key devices such as the refrigerant identifier, electronic leak detection tool and temperature gun all need to be tested and adjustments made to ensure they are performing to manufacturer specifications.

Refrigerant Recovery/Recycle & Charging Station

This all-important tool needs a complete pre-season inspection.

Areas of concentration include changing the oil in the vacuum pump, calibrating the scales and gauges, inspecting all hoses for cracks and splits, checking the gauges for leaks, purging the storage tanks of air, replacing particulate and oil filters, and examining the O-rings at the service couplers for wear.

Recovery Reservoir Oil Check

To avoid inaccurate measurements by the recovery reservoir, you should also check it for "leftover" oil from the previous season.

A deep vacuum test is also highly recommended. If your unit can't achieve a deep vacuum, you won't be able to secure a proper charge of the refrigerant and oil following a repair.

An improper refrigerant charge can lead to premature component failures, particularly with compressors.

EPA Certifications

Each technician needs to be certified by the Environmental Protection Agency to handle refrigerants.

Testing is involved to obtain the certification.

Oil and O-Rings

Most A/C system oils and lubricants have an expiration date. Survey your inventory and replace as needed.

Another good supply check is O-rings. They should be inspected for cracks and splitting.

Consider Upgrading Your Tool Box

Unfortunately, spanner wrenches won't work on newer-style compressor clutches. If you haven't invested yet in a compressor turning tool, now's the time.

You might also want to consider adding a tool such as Delphi's new A/C Analyzer to your tool box. This unique device measures eight key air-conditioning system areas to help take the guesswork out of servicing today's A/C systems.

The hand-held, wireless device links to any Bluetooth¨-equipped PDA and services R-134a systems.

Visit our Technician Library for access to Documents and Downloads

Get in touch

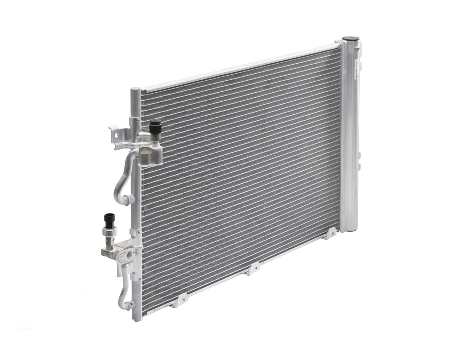

The full Delphi Air Conditioning product range

Find out where to buy Delphi parts

.tmb-460w.jpg?Culture=en-GB&sfvrsn=c70917c0_6)