Cabin Air Filters

High-performance media

All our cabin air filters use a high-performance, non-woven fabric to eliminate dust, pollen, bacteria and exhaust particles, amongst others. The specially designed filter fabric contains up to five individual layers, removing near 100 percent of harmful pollutants.

Enhanced protection

Over time moisture can build up in the filter and become a feeding ground for bacteria and mould. This can then spread into the lines of the HVAC system, where it emits unpleasant odours. For the ultimate protection from this and other pollutants, we also offer a range of carbon activated filters. Our carbon activated filters feature the same high quality, non-woven fabric as our particle filters, with the addition of a layer of activated carbon. Sandwiched between two layers of fleece, this highly effective technology removes more pollutants than standard filters, and expels nasty gases and smells too.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Stock Up for Thermal Season. Year Round! If you think thermal season is just one season, think again.

Resource Highlights

Thermal part failures can occur all year round, not just in summer. Garages should be prepared for these types of repairs and the untapped selling opportunity they could provide. Stock up for profitability with these simple and insightful tips from Delphi.

Why stock year round?

Thermal part failures can occur all year round, not just in summer. Garages should be prepared for these types of repairs and the untapped selling opportunity they could provide. Stock up for profitability with these simple and insightful tips from Delphi.

As you’re aware, the heater core is necessary in winter to heat and demist the cabin. But did you know it’s one of the primary thermal repair opportunities in the winter with main failure causes include leaking or clogs that may occur if the coolant is not checked and/or changed regularly?

This is the same for AC compressors. Failure can occur anytime, and as the compressor is the heart of the A/C system, the vehicle cannot run without it.

Diesel Systems Buzz Tool

As for maintenance products, there is no particular period to service a car even when it comes to AC components. The receiver drier filters the refrigerant to capture small debris and moisture. Saturated with a small volume of water, it must be checked and changed regularly (every 2-3 years and each time the system is opened). The cabin filter purifies the air coming into the cabin, and efficiently retains small particles of pollution in the atmosphere. It’s necessary to change it every 12 months (10,000 miles) – every 6 months with urban use. Particle cabin air filters remove particles from the air too large to pass through the filter. Activated carbon air filters are more effective and retain smaller particles of pollutants, chemicals, gases, cigarette smoke and other toxins.

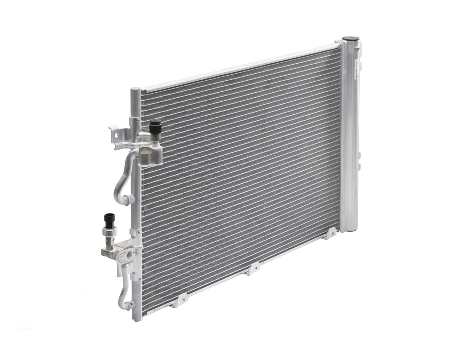

Besides general part failures and maintenance/service opportunities, in front end crashes, the main heat exchangers (which are located at the front end of the vehicle) are often directly impacted. These parts include radiators, condensers, charge air coolers, cabin air filter and heater cores. Delphi provides the aftermarket with almost 100 percent coverage on compressors, radiators, charge air coolers and condensers and its total, first-to-market, all makes thermal product offering has 92 percent application coverage with more than 2,040 part numbers.

Diesel Systems Fuel Analyser

Beyond parts, it’s important to be prepared when a garage comes in requesting advice and recommendations regarding new thermal equipment. This is your opportunity to demonstrate your thermal expertise on how a garage should tool up for service and repairs.

Key devices such as the refrigerant identifier, electronic leak detection tool and temperature gun all need to be tested and adjustments made, as required, to ensure they are performing to manufacturer specifications. A little preventative maintenance will go a long way.

Charging Stations

The refrigerant recovery/recycle and charging station is one of the most important tools for a technician conducting repairs. Not only does the RRR machine need annual, complete pre-season inspection, but Delphi also provides four different types of RRR machines to keep your customers happy.

Delphi introduced the four air conditioning (A/C) recharging stations to its service portfolio in September 2011. These machines deliver quick, accurate recovery, and recharging of passenger and commercial vehicle thermal systems including hybrid and electric vehicles. Each system features a patented aluminum manifold which delivers efficient refrigerant recovery, enhanced leak protection, and easier assembly and access.

Check Expiration Dates

Most A/C system oils and lubricants have a shelf life. Using anything that's past the expiration date could damage the system you've just repaired. Another good supply check is O-rings. These, too, won't last forever. Ask your customers if their oils, lubricants and O-rings are up to date. It could save them an unnecessary comeback and unhappy consumer.

Spanner Wrenches

Unfortunately, spanner wrenches won't work on newer style compressor clutches. Ask your customers if they’ve invested yet in a compressor turning tool. You might also want to consider recommending they add a diagnostics tool such as Delphi's new A/C Analyzer to their garage. This unique device measures eight key air-conditioning system areas to help take the guesswork out of servicing today's A/C systems. The hand-held, wireless device links to any Bluetooth-equipped PDA and services R-134a systems.

Thermal Technologies Entering The Aftermarket.

Technology is constantly evolving. Today’s technicians should be aware of the technologies found on new production vehicles. Those will be the aftermarket vehicles of tomorrow. Take for example Delphi’s new technology Phase Change Material (PCM) storage system. One of the unique characteristics of a hybrid vehicle is its engine can shut-off at any time during a drive cycle, such as while waiting at a stop sign or stop light, which increases fuel efficiency and reduces emissions. Conventional vehicles use an air conditioning compressor that is belt-driven by the engine. When the engine shuts off, so does the air conditioning system. To help keep passengers comfortable when this happens, Delphi has developed a PCM storage system.

This thermal storage system enables a hybrid or electric vehicle to store excess thermal energy while the engine is running efficiently and then releases this energy during engine-off idle stops or when the vehicle is running inefficiently. This means the air conditioning system is turned off but the vehicle is still comfortable. The expected launch of this technology in new production vehicles is 2014.

Is Your Garage Ready?

Stocking up to profitability doesn’t involve just parts. It’s important to educate your team to the new technologies entering the market, as well as the services and training offered by suppliers to support the parts you stock. Is your garage ready?

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Air Conditioning product range

Find out where to buy Delphi parts

.tmb-460w.jpg?Culture=en-GB&sfvrsn=c70917c0_6)