EGR Valves

As its name suggests, the exhaust gas recirculation valve – EGR valve for short – recirculates finely metered quantities of exhaust gas to the engine intake system. By simply altering the chemical makeup of the air entering the engine and thus lowering the temperatures in the combustion chamber, it reduces the production of NOx for a much cleaner, more efficient exhaust. With so much at stake, you’ll want to fit a quality brand with proven OE technology…just like ours.

- Product Information

- Product Resources

- Enquire

- Related Products

Exhaust Gas Recirculation Valve OE technology

With over 20 years OE EGR system expertise, our valves are fitted as OE to millions of vehicles worldwide. We bring this same expertise to the aftermarket, with a comprehensive range including rotary and linear configurations, all based on our proven electronically actuated EGR valve technology.

Built for tough conditions

Because of the harsh environment of its location on the intake manifold, we only use the highest quality materials such as robust stainless steel valves, high temperature internal components and RTV silicon seals. The result – a quality EGR valve, highly resistant to extreme heat, contamination, corrosion and wear.

Precision engineered

Even the smallest of differences in the shape of the valve head can affect both valve leakage and flow metering, leading to increased fuel consumption, carbon build-up and decreased vehicle performance. That’s why every Delphi EGR valve is precision engineered to match the OE design.

Super quick response time

All our valves feature fast opening and closing response times for enhanced engine control and lower emissions from reduced exhaust gas lag. The high opening and closing force also helps to minimize the impact of corrosion, ensuring a longer lasting part.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

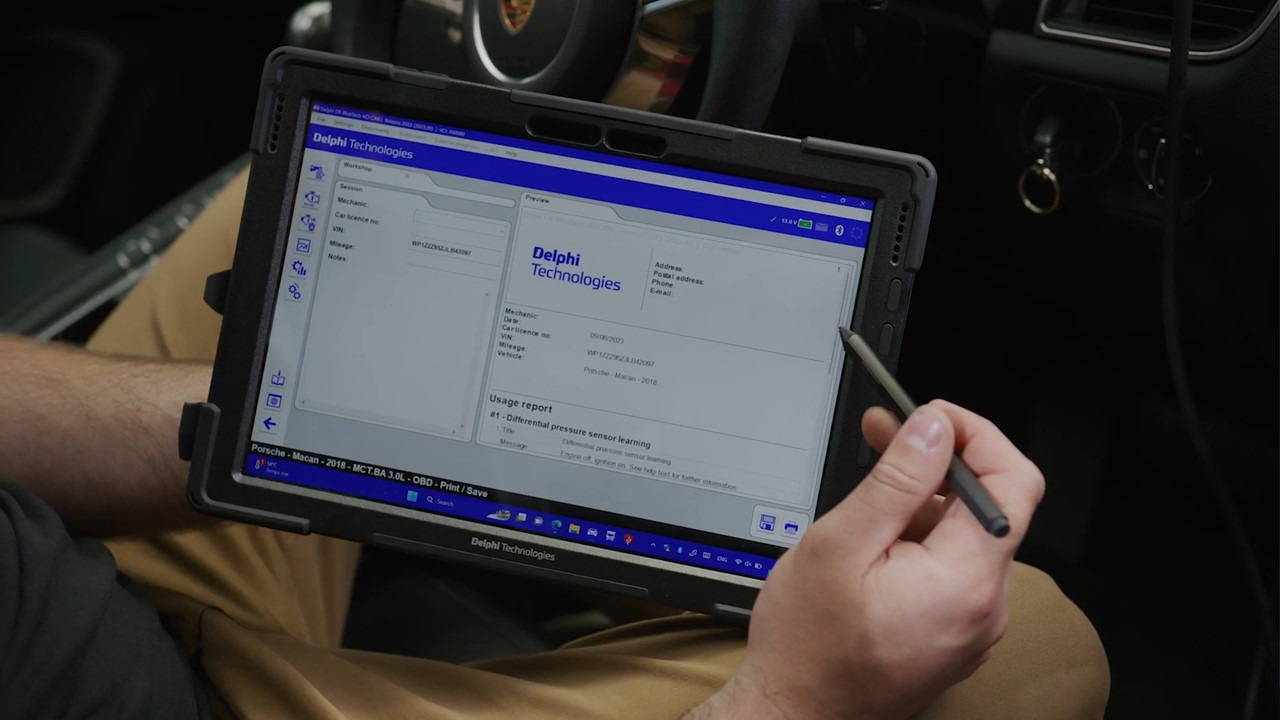

Support through tools, tips and training

Related product resources and downloads

Get in touch

The full Delphi Emissions product range

Find out where to buy Delphi parts