Resource Highlights

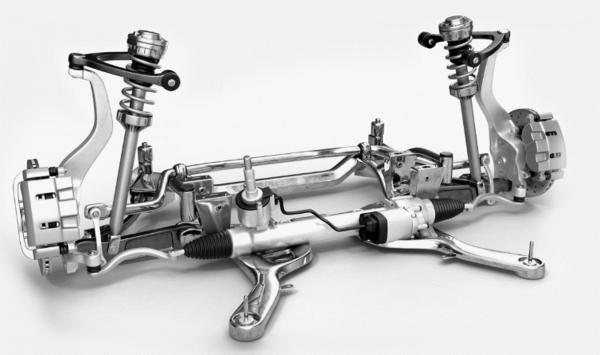

In this article you will find out about everything you need to know regarding the Steering and Suspension replacement.

Here are some suggestions for your steering and suspension replacements -- specifically control arms and ball joints:

- You will need a ball joint press tool and possibly a ball joint separator tool as well (learn more about how to use those tools here). Some auto parts stores will rent them for free.

- Pneumatic/electric tools will make your job easier but are not necessary.

- Be prepared for the project to take at least three hours depending on your skill level and tools available. A control arm replacement would typically be a medium to high level of difficulty due to the labor intensity and special tools required.

- If you are replacing your control arm or ball joints due to an issue, or if you are doing preventive maintenance on an aging vehicle, consider inspecting and/or replacing the shocks and struts at the same time, as well as the brakes. After all, part of the job may require you removing them, so while you are doing this, it may be a good opportunity to install replacement units if necessary.

Remove, tighten and torque

- Soak the nuts with penetrating spray in advance to make components easier to remove.

- Always use a torque wrench to tighten fasteners to the vehicle manufacturer’s specifications. Reminder: when using air tools there is the potential to damage components.

- Tighten all wheel bolts to the vehicle manufacturer’s torque specifications.

- Torque components in their loaded position, not wheel-free. This will prevent the components being under additional stress when the vehicle is on the ground.

- Never re-use fasteners. Steering and suspension systems use nuts with a self-locking feature to prevent looseness due to vibration. Most nut locking features are designed for single use only.

- If a control arm is fitted with horizontal bushings, tighten the bolts while the vehicle is at its neutral ride height. Tightening with the vehicle in the air can lead to excessive wind-up of the bushings when back on the ground and under compression.

Watch our videos to learn:

After replacement

The vehicle will need an alignment to reset the steering geometry after replacing any steering or suspension component, since the new components will have less play and set the wheels at a slightly different angle.

On a four-wheel drive vehicle:

- Adjust camber on the rear wheels, if possible.

- Adjust toe on the rear wheels.

- Adjust caster and camber on the front wheels, if possible.

- Adjust front toe to match the rear thrust angle

Align the wheels

An alignment shop with proper tools will need to make sure the wheels are properly aligned after you complete any steering & suspension work. Check all three angles -- toe, camber and caster -- to minimize rolling resistance, friction and tyre wear. Adjust as necessary.

Check the toe:

- Why the toe changes: Replacing tie rod ends, tie rods or a steering rack will alter the distance between the steering arms, which impacts the toe.

- After the parts have been installed, measure the vehicle’s toe. Adjust the tie rods to set toe within the vehicle manufacturer's specifications.

Check the camber:

- Why the camber changes: The constant movement of a vehicles’ suspension system can change the geometry of the control arms and struts.

- The camber is not normally adjustable, so if the measurements are noticeably different either side, check the tyres, wheels or suspension for distortion.

- What happens if the camber is not equal on both sides of the vehicle? If the difference is not large, this may mean irregular tyre wear. If the difference is large, the vehicle will pull to the side with the most positive camber.

Check the caster:

- Caster can affect the vehicles’ steering stability, effort and return.

- Generally speaking, caster should be within 0.5 of a degree, side-to-side. Any measurement greater than this can cause a drift to one side and will need to be reset.

- Caster is generally not adjustable on modern cars.

- What happens if caster is not equal on both sides of the vehicle? The vehicle will pull to the side with the least amount of caster (which may mean the most negative caster).

Finally, check all of the mounting nuts and bolts to ensure that they are all correctly tightened.

Alignment for vehicles with ADAS components

Newer vehicles may have Advanced Driver Assist Systems (ADAS) which include safety features such as Adaptive Cruise Control, Lane Keep Assist and Collision avoidance. These enhanced safety systems rely on the vehicle's cameras and radar sensors being accurately aimed and calibrated. When an chassis alignment is performed subsequent to a suspension or steering component replacement, some vehicles’ ADAS components may require one or both of the following service calibrations:

- Static Calibration:Performed in the repair shop using precision aiming / calibration equipment along with a diagnostic scan tool while the vehicle is stationary.

- Dynamic Calibration: Performed during an extended road test using a diagnostic scan tool

On vehicles with ADAS options, a shop must always perform a complete 4-wheel alignment which includes the vehicle’s thrust angle measurement. Failure to follow recommended OEM procedures such as a proper 4-wheel alignment and proper ADAS camera / radar calibration could result in reduced functionality or erratic system performance with these safety enhancing ADAS systems. If an ADAS equipped vehicle is not properly serviced, problems can occur, ranging from the vehicle’s collision avoidance system abruptly applying the vehicle’s brakes for no apparent reason to the collision avoidance system not detecting an impending crash. Consult OEM service information for more details.