CRi-PC

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

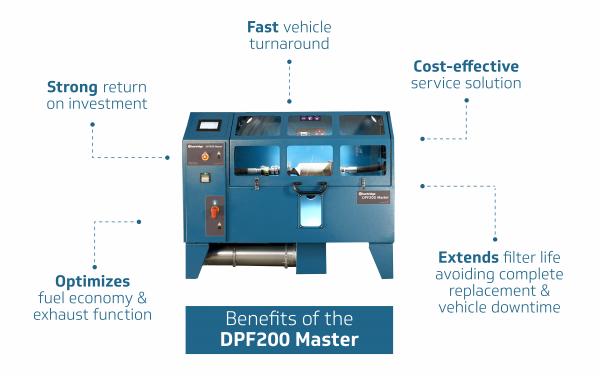

The DPF200 Master: A win-win in particulate filter repairs for both garages and vehicle owners.

Resource Highlights

In this article, we discuss the DPF200 Master: A win-win in particulate filter repairs for both garages and vehicle owners.

With some 60 million European car and light commercial vehicles fitted with particulate filters, a tremendous business opportunity exists for garages as the devices age and fail. But, as is often the case, one person’s gain is another’s source of pain. That’s certainly true for vehicle owners when handed a particulate filter repair bill that can climb into the hundreds, and sometimes, even thousands of pounds! So, what to do? The best solution may be to clean – not replace – the filters. And the best way to clean them: The Hartridge DPF200 Master. This fast, effective diagnostic and cleaning solution for gas and diesel particulate filters provides a win-win that can lead to new shop profits and longer lifetime of vehicles.

Particulate filter basics and background

Diesel particulate filters, or DPFs, first appeared on the scene in 2009. Vehicle manufacturers introduced them in order to comply with Euro-5 emissions standards. Its basic function is to trap the harmful particles produced during the combustion cycle, preventing their release into the atmosphere. The technology proved so effective that automakers soon adapted them for use on gas engines. Aptly named the GPF, or gasoline particulate filter, the device is now found on brands such as Volkswagen, Audi, Mercedes and Ford, and is expected to remain an essential powertrain component moving forward.

With particulate filters, the trapped soot must be emptied or 'burned off' periodically through a process known as regeneration. The challenge here: auto regeneration only occurs when the exhaust hits certain temperatures. Fail to hit those temps, say due to frequent start-stop journeys, then soot will build up and the filter becomes blocked. And a blocked filter can often be the cause of an emissions failure in an annual inspection.

Now, it is possible to carry out a forced regeneration via a diagnostic scan tool such as our DS solution. However, having it professionally cleaned is economically and environmentally the best option.

The Hartridge DPF200 Master helps vehicles drive cleaner and further

With our new Hartridge DPF200 Master, garages can quickly return the filter’s back pressure to OE standards. By restoring the DPF, it will optimize fuel economy, improve exhaust function and extend the life of the filter, avoiding unscheduled vehicle down time and expensive replacements, and ultimately minimizing costs for the vehicle owner.

Featuring an easy-to-use software package that can identify faulty filters prior to cleaning, and a patented bi-directional dry air cleaning process that pulses high volumes of compressed air at both ends of the filter, the machine is also faster and safer than other cleaning solutions available. This means that garages can clean a high number of filters per day, leading to faster vehicle turnaround times and faster profits. A typical workshop diagnosing and cleaning just four filters a week can see a return on their investment in a DPF200 Master in less than two years. So, invest in a Hartridge DPF200 Master today, and ‘clean-up’ on a fast-growing and profitable market in more ways than one.

For more on the Hartridge DPF200 Master, read our press release or visit Hartridge's DPF200 page.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Hartridge product range

Find out where to buy Delphi parts