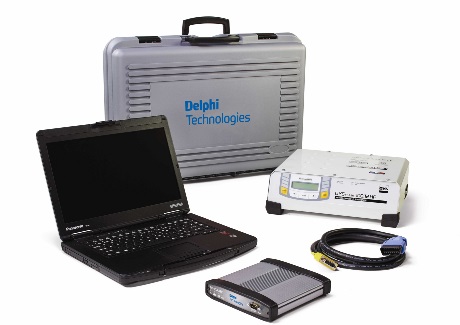

HK1400 Expert

Affordable yet full of features, the HK1400 is highly accurate, robust, flexible and user friendly. The essential choice for any diesel workshop wanting to increase their EUI and EUP diagnostic capability. An application kit is also available to allow testing of Cummins HPi®.

HK1400 Universal Test Bench

The HK1400 is designed to bridge the gap between OEM approved EUI/EUP repair workshops and the general diesel EUI/EUP repair market.

The HK1400 has been engineered so that there is no compromise on accuracy and repeatability of test results, yet the solution has to be affordable for all progressive diesel workshops worldwide. By utilizing and adapting our existing magmah software and keeping development costs to a minimum, it has enabled us to focus on the engineering of the hardware to ensure you get the best there is.

Contact your local Central Distributor for purchase details.

Hartridge Test Plan Database

Test plan database includes coverage for Denso®, Delphi®, Cummins®, and more….

All the testplans, where applicable, include response time limits and they have all been extensively validated to ensure accuracy and to enable workshops to test EUI/EUP to the highest possible standards.

Key EUI/EUP Test Functionality

- Response time measurement

- Electrical resistance

- Fully configurable pulse widths

- Injected quantity shot count

- Automatic test limits generator

- Printable test results and analysis

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article you will find out about how to use Delphi’s Electronic Injector Kit.

Buzz Tool | Today’s Common Rail injector coils typically have low resistance and cannot be measured using a standard digital multimeter (DMM). In fact, it’s simply not enough to measure resistance to determine a coil’s health; technicians need to measure inductance for an immediate and accurate assessment. Until now, separate tools including a DMM, Megohmmeter, Millohmeter, LCR meter and signal generator would be needed for this. But not any longer! Delphi’s Electronic Injector Kit combines all of this into a single, economical and easy to use hand-held tool by measuring resistance and inductance of the coil in the injector, checking for coil open/short circuit and the insulation of the coil to the injector body and driving the valve to make it BUZZ, proving the valve is not stuck from lacquering deposits. This diagnosis can ensure significant time and cost savings for the garage. The kit is designed to be used on or off vehicle and offers two cycles:

|

Step 1 | Select the correct adaptor cable from the complete range supplied with the kit. Connect one end to the test unit. Note the YDT720 kit is not compatible with direct or indirect operation piezo-electric injectors. |

Step 2 | Connect the green crocodile clip to the green banana connector on the test cable, then clip to the injector body, or another solidly secured component (HP pipe, engine block etc.). This is to ensure the insulation test function is carried out during the test cycle. |

Step 3 | Connect the supply cable connectors to the vehicle battery. Red to the battery +ve and black to the –ve/0V). The battery must be in good condition and supplying a 15 to 25a current. |

Not Just Brakes. Delphi Brakes | Power up! Once connected to the injector, press the button to start the electronic test. The unit will then:

If any of the above faults are detected, the tool will clearly display the fault found and will not progress to the measurement stage. If not, it will measure and display:

Compare each injector to the other injector results and look for any noticeable differences, which are an indication of failure. Check the back of the users’ manual for a record sheet to record these values. |

Step 5 | Following the measurement, press continue and carry out the BUZZ test. During the control sequence, the test injector will make a characteristic audible buzzing noise, which is an indication that the injector valve has free movement and is not suffering from lacquering. Repeat the above steps for each injector on the vehicle being tested. * While the Electronic Injector Test Kit is designed to be used as a stand-alone product for electronic diagnostics of Common Rail solenoid injectors, to carry out the injector cleaning operation it must be used in conjunction with our Solvent Cleaner Kit. |

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Hartridge product range

Find out where to buy Delphi parts