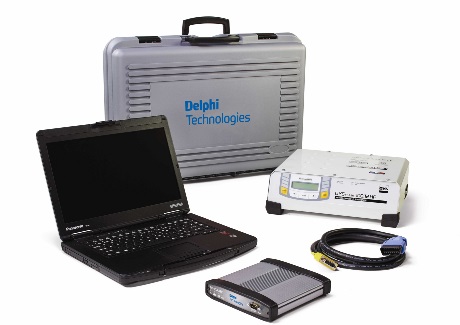

HK1400 Expert

Affordable yet full of features, the HK1400 is highly accurate, robust, flexible and user friendly. The essential choice for any diesel workshop wanting to increase their EUI and EUP diagnostic capability. An application kit is also available to allow testing of Cummins HPi®.

HK1400 Universal Test Bench

The HK1400 is designed to bridge the gap between OEM approved EUI/EUP repair workshops and the general diesel EUI/EUP repair market.

The HK1400 has been engineered so that there is no compromise on accuracy and repeatability of test results, yet the solution has to be affordable for all progressive diesel workshops worldwide. By utilizing and adapting our existing magmah software and keeping development costs to a minimum, it has enabled us to focus on the engineering of the hardware to ensure you get the best there is.

Contact your local Central Distributor for purchase details.

Hartridge Test Plan Database

Test plan database includes coverage for Denso®, Delphi®, Cummins®, and more….

All the testplans, where applicable, include response time limits and they have all been extensively validated to ensure accuracy and to enable workshops to test EUI/EUP to the highest possible standards.

Key EUI/EUP Test Functionality

- Response time measurement

- Electrical resistance

- Fully configurable pulse widths

- Injected quantity shot count

- Automatic test limits generator

- Printable test results and analysis

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article you will find out about the importance of renewing High Pressure Pipes.

Make | Model | System |

Audi | All Common Rail applications | Diesel Systems |

Alfa Romeo | All Common Rail applications | Diesel Systems |

BMW | All Common Rail applications | Diesel Systems |

Citroen | All Common Rail applications | Diesel Systems |

Dacia | All Common Rail applications | Diesel Systems |

Fiat | All Common Rail applications | Diesel Systems |

Ford | All Common Rail applications | Diesel Systems |

Honda | All Common Rail applications | Diesel Systems |

Hyundai | All Common Rail applications | Diesel Systems |

Jaguar | All Common Rail applications | Diesel Systems |

Kia | All Common Rail applications | Diesel Systems |

Land Rover | All Common Rail applications | Diesel Systems |

Nissan | All Common Rail applications | Diesel Systems |

Peugeot | All Common Rail applications | Diesel Systems |

Skoda | All Common Rail applications | Diesel Systems |

Suzuki | All Common Rail applications | Diesel Systems |

Ssangyong | All Common Rail applications | Diesel Systems |

Toyota | All Common Rail applications | Diesel Systems |

Vauxhall | All Common Rail applications | Diesel Systems |

VW | All Common Rail applications | Diesel Systems |

Volvo | All Common Rail applications | Diesel Systems |

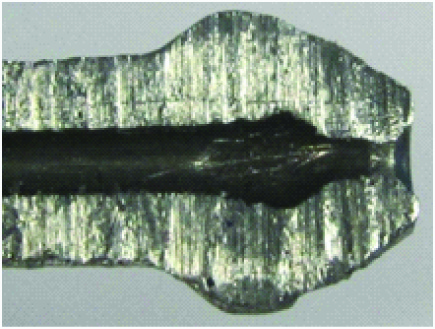

Importance of Renewing High Pressure Pipes | It is important to consider renewing the high pressure pipes on Common Rail systems after any intervention on the high pressure system. This is for a number of reasons: 1. To prevent leakage.When a pipe gland is tightened on first application, the surface of the sealing dome is deformed to provide a tight seal between the pipe and injector / rail / pump components. If the pipe is subsequently re-used the pipe further deforms but is also work hardened so a tight seal is more difficult to achieve. 2. To prevent dirt or swarf ingress.When a screw thread is tightened, minute particles of swarf are generated and are encased within the grooves of the screw thread. When the thread is released these particles are free and subsequent re-use may dislodge these particles and contaminate the component being worked on. 3. Hydraulic performance.When the pipe gland nut is tightened the dome of the pipe deforms. Subsequent re-use will continue to deform the sealing edge as described above. However, the other consideration is that the bore of the pipe deforms and can cause restriction of flow, which in turn affects performance of the fuel system and also the engine. |

Figure 1 | The pipe in figure 1 shows a cross-section of a pipe after single use and the bore is unrestricted. |

Figure 2 | Figure 2, however, shows a pipe after multiple uses and clearly the pipe diameter is restricted. |

Safety First | When fitting pipes after repair it is imperative that the correct torque is applied to the gland nut. Exceeding the torque risks the scenario in figure 2 as the pipe will excessively deform, but also not achieving the correct torque will risk high pressure leaks. In all cases respect health and safety when working on high pressure systems and ensure the operatives are correctly trained in the service routines for Common Rail systems. |

Further Information | Read the relevant Common Rail workshop manual on Direct Evolution:

|

Tools & Equipment |

|

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Hartridge product range

Find out where to buy Delphi parts