VTI HEAVY DUTY

- Product Information

- Product Resources

- Enquire

- Related Products

What’s included in the HEAVY DUTY package?

The HD package is available in 3 levels.

- VTI Truck Professional

Maintenance items, including service schedules, adjustment data and lubricants, torque settings and repair manuals.

- VTI Truck Business

As professional PLUS wiring diagrams (ABS and Engine management), repair times.

- VTI truck Ultimate

As Professional & Business PLUS Light commercial vehicles, additional 2 licences to be used simultaneously.

Let's now look at the details ...

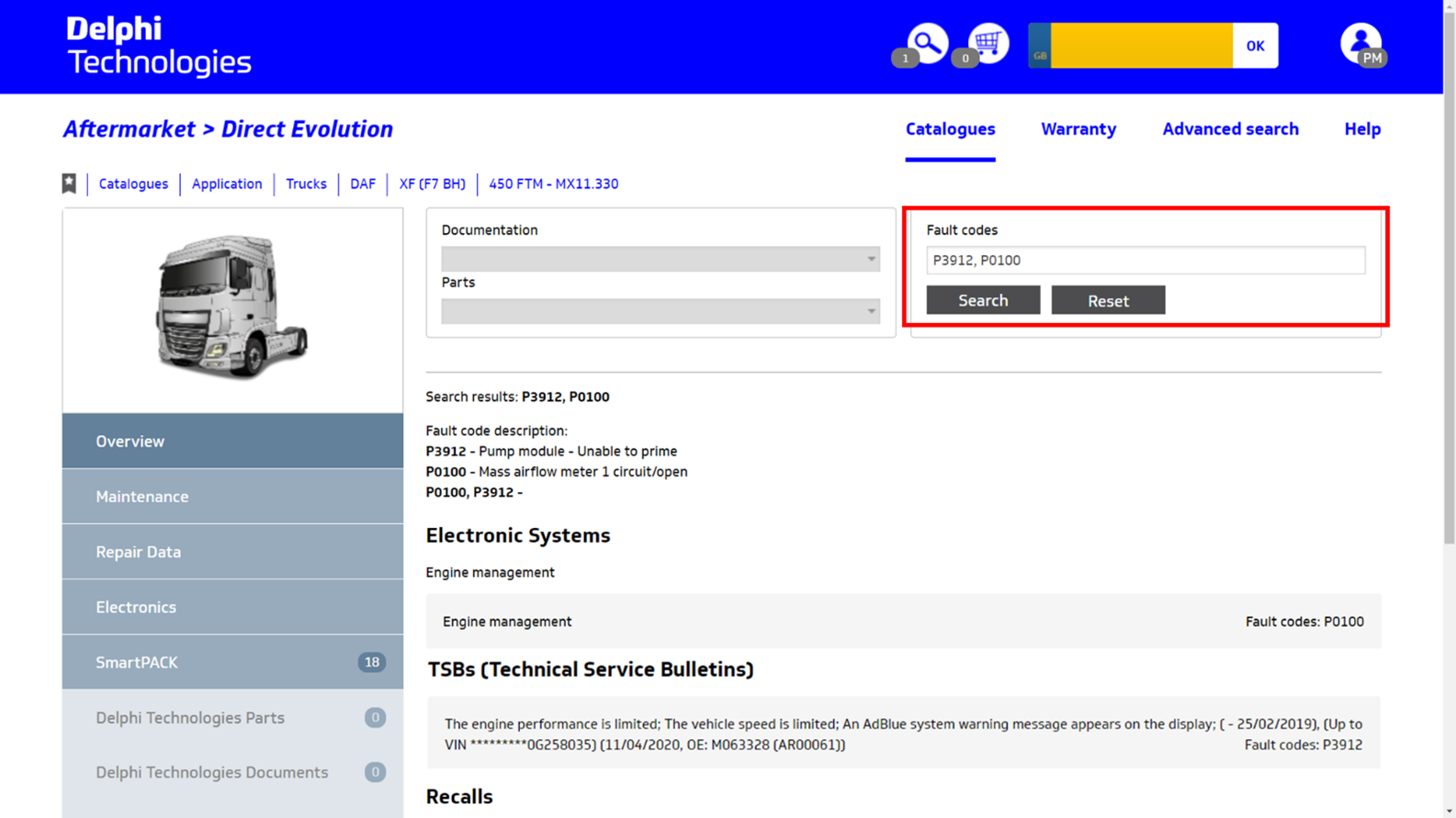

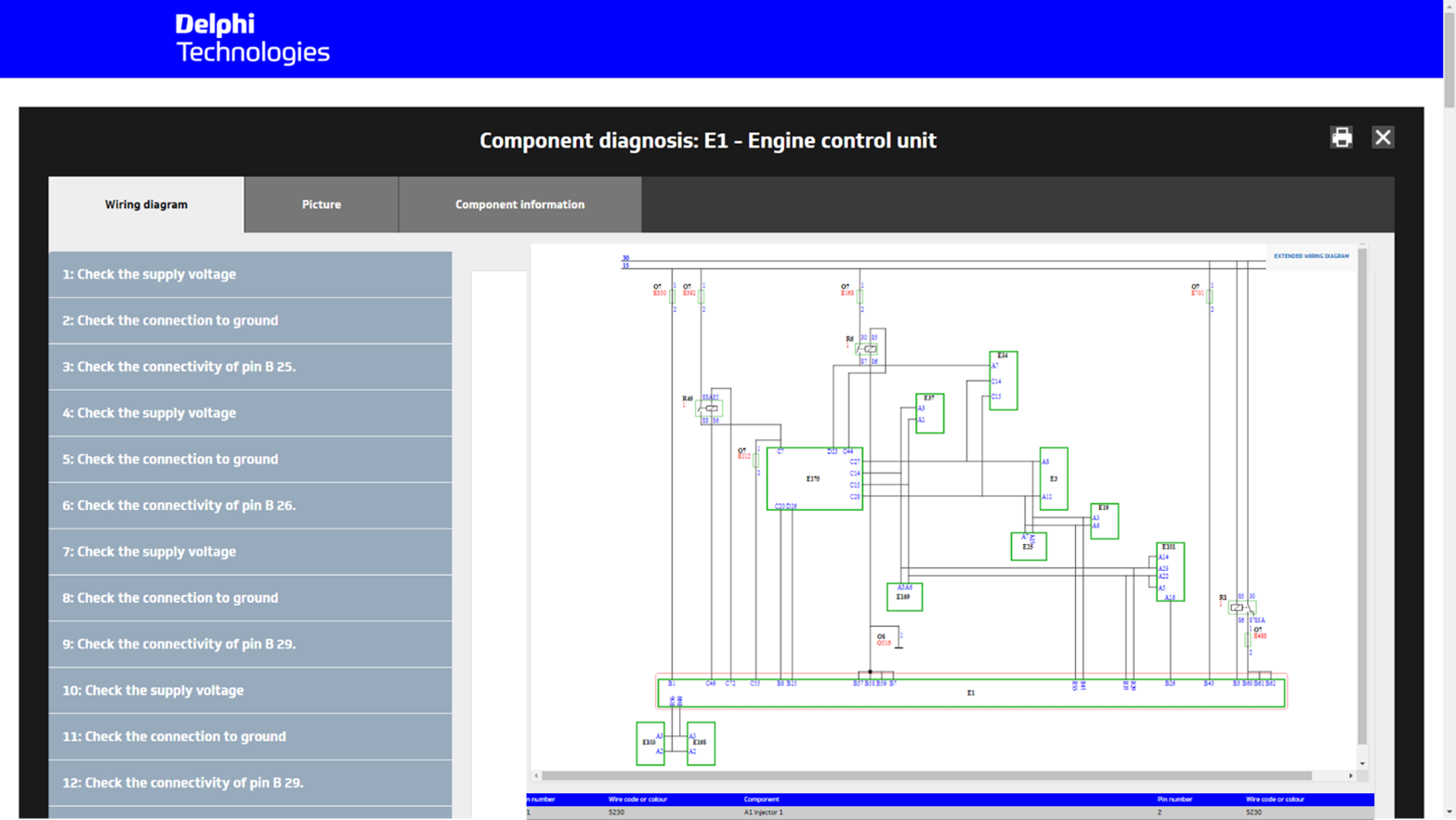

• Guided diagnostics database

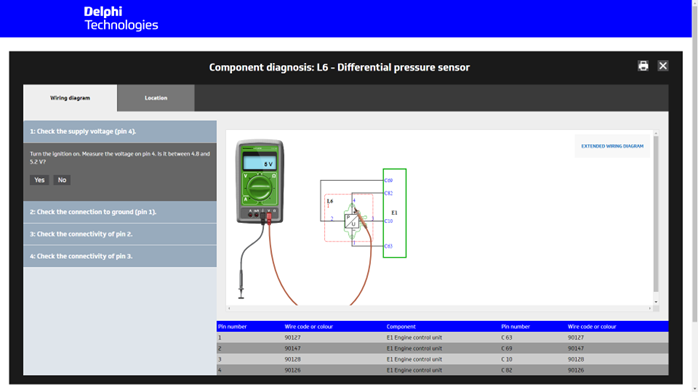

Full guided diagnostics from both fault codes, and component troubleshooting.

Includes detailed information at each stage for the technician.

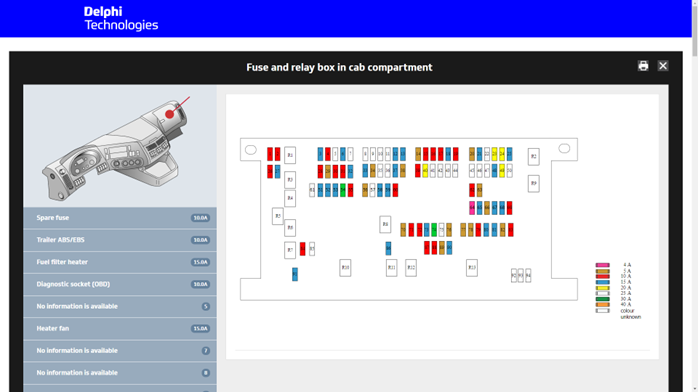

Fuses and relay locations: easy to locate, and identify correct fuses, relays, bus bars and more.

Wiring diagrams: diagrams which make troubleshooting easier.

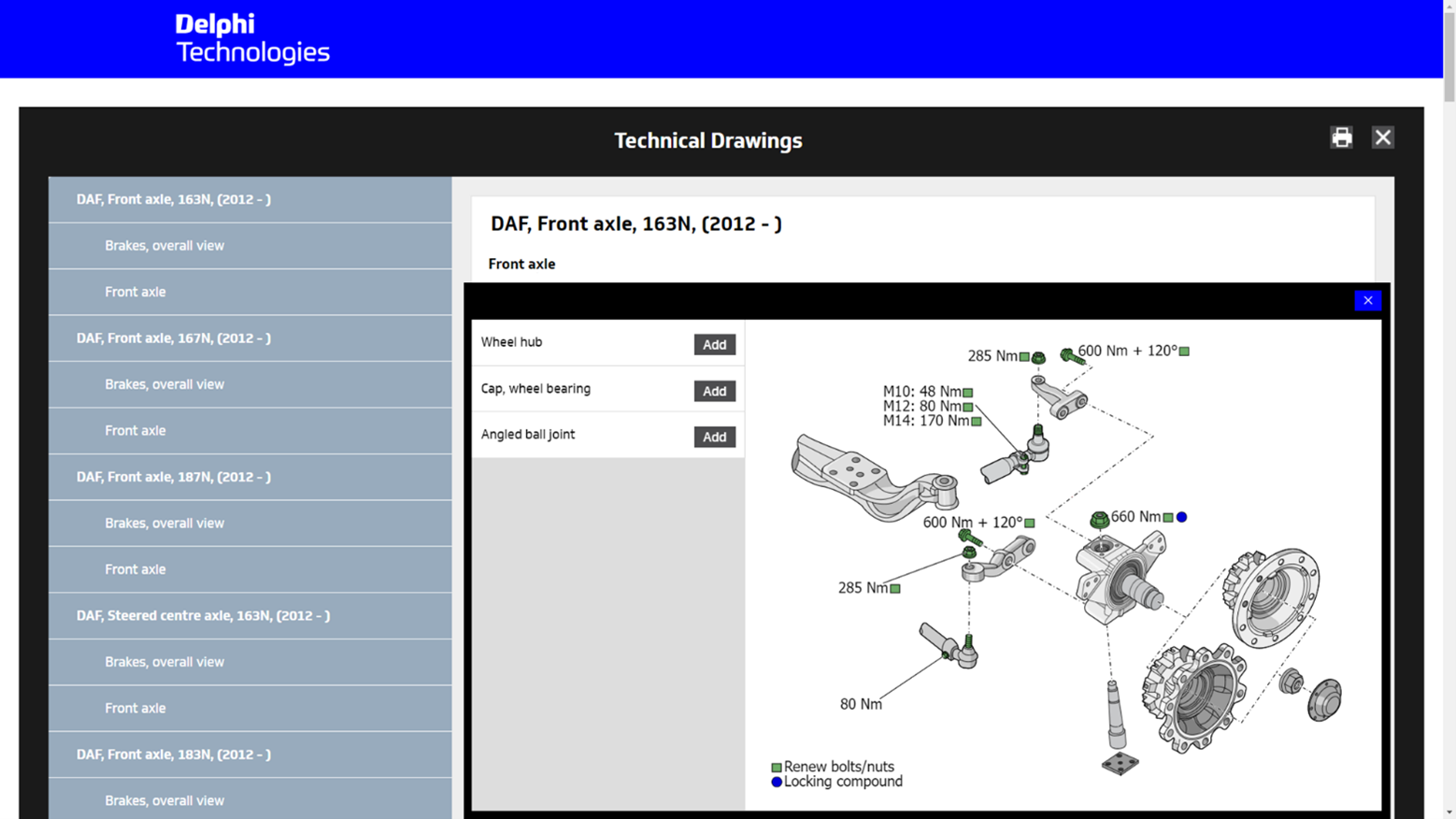

Torque figures and technical drawings: torque figures are shown in a drawing format, this makes it much easier for the technician to locate the correct data. This is especially important when dealing with complicated multi-link suspension.

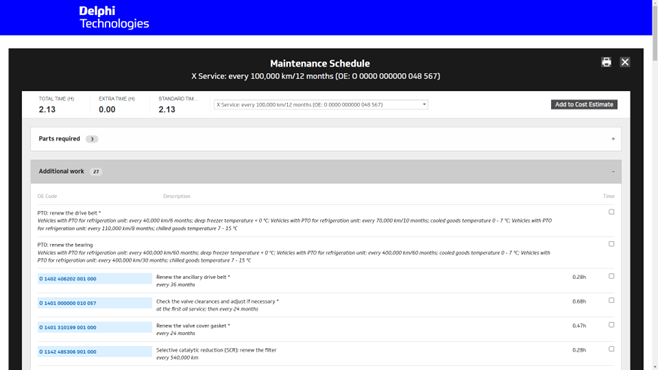

OE service and maintenance schedules: with the OE service number shown.

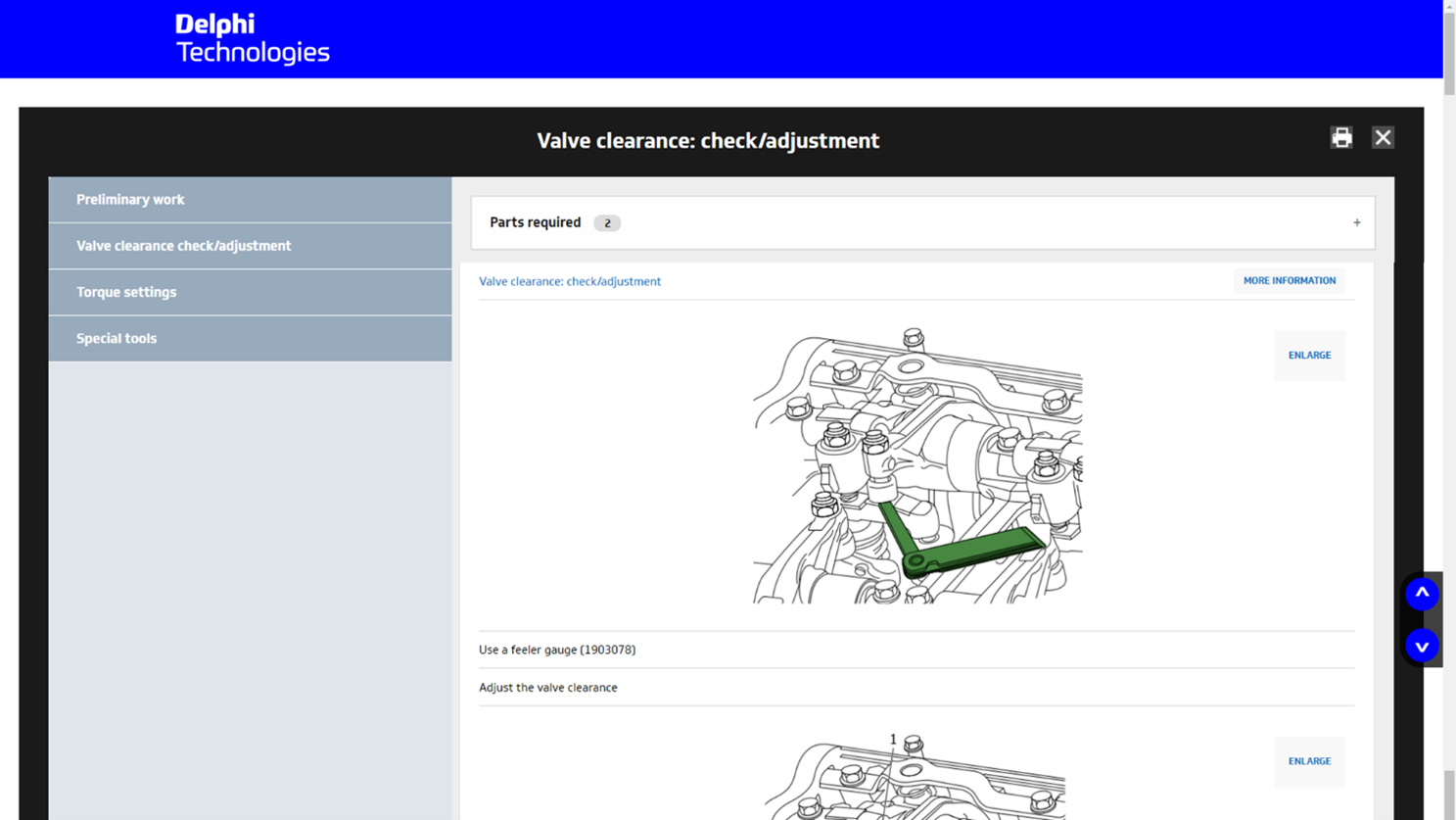

Repair manuals: VTI offers full guided repair manuals included timing belt / chain instructions, Transmission, Steering and Suspension, Brakes, plus Interior and Exterior trim instructions.

Are you interested in Vehicle Technical Information for a car or light commercial vehicle?

Check out the VTI CAR.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we take a look at random fault codes regarding misfires on VW 1.9 PD applications.

Vehicle Applications

Make | Model | Systems |

Audi | 1.9 PD applications (including A3 & A4) | Diesel Systems |

Seat | 1.9 PD applications | Diesel Systems |

Skoda | 1.9 PD applications (including Octavia) | Diesel Systems |

VW | 1.9 PD applications (including Golf, Passat, Bora) | Diesel Systems |

Summary

Intermittent codes, for example 18074 /5 /6 /7 (cylinder x misfire) can randomly occur and in some cases be single or multiple incidences.

This fault code type is more likely to arise with older or high mileage vehicles as the injector wiring loom is internally mounted on the cylinder head and subjected to temperature extremes, vibration and lube oil, causing degradation of the connectors.

Resolution

Vehicles displaying this type of fault can be readily diagnosed by doing a “wiggle” test on both the main harness connector and the injector connectors while checking for continuity. The injector loom is available as a service part, and can be fitted in place, but the security of the main loom connector must be checked. This is best done by using an old connector of the same type and probing the connector to check for security.

It is possible to tighten the connectors, but in either case a further wiggle test is advised after repair to ensure continuity exists from the main connector to the injectors. Where possible a continuity test can be done at the ECU harness to validate the complete circuit.

Most likely failures will be the connectors and also the most cost effective to repair. In all cases the security of the wiring must be confirmed as further mechanical intervention is costly.

However if the Unit injector is suspected, the coil resistance can be checked on each individual injector. Typically this should be 0.3 to 0.7 ohms on the injector connections with the loom disconnected. Short to ground should also be checked between each terminal and the injector body.

If any injector is open or short circuit then the item must be replaced. A fully serviced / exchange / new item should be available at your local Diesel Centre, who can also provide “on bench” diagnostic and repair for unit injectors.

Tools & Equipment

Part Number | Description | Operation |

PEM1003 | Inteliprobe Kit | Interchangeable probes which permit wider range of testing |

PEM1000 | Terminal Tool Kit | For removing vehicle computer connectors and terminals. |

PEM1013 | Automotive Multimeter | Testing of voltages and resistance |

Resource Highlights

In this article, we take a look at random fault codes regarding misfires on VW 1.9 PD applications.

Vehicle Applications

Make | Model | Systems |

Audi | 1.9 PD applications (including A3 & A4) | Diesel Systems |

Seat | 1.9 PD applications | Diesel Systems |

Skoda | 1.9 PD applications (including Octavia) | Diesel Systems |

VW | 1.9 PD applications (including Golf, Passat, Bora) | Diesel Systems |

Summary

Intermittent codes, for example 18074 /5 /6 /7 (cylinder x misfire) can randomly occur and in some cases be single or multiple incidences.

This fault code type is more likely to arise with older or high mileage vehicles as the injector wiring loom is internally mounted on the cylinder head and subjected to temperature extremes, vibration and lube oil, causing degradation of the connectors.

Resolution

Vehicles displaying this type of fault can be readily diagnosed by doing a “wiggle” test on both the main harness connector and the injector connectors while checking for continuity. The injector loom is available as a service part, and can be fitted in place, but the security of the main loom connector must be checked. This is best done by using an old connector of the same type and probing the connector to check for security.

It is possible to tighten the connectors, but in either case a further wiggle test is advised after repair to ensure continuity exists from the main connector to the injectors. Where possible a continuity test can be done at the ECU harness to validate the complete circuit.

Most likely failures will be the connectors and also the most cost effective to repair. In all cases the security of the wiring must be confirmed as further mechanical intervention is costly.

However if the Unit injector is suspected, the coil resistance can be checked on each individual injector. Typically this should be 0.3 to 0.7 ohms on the injector connections with the loom disconnected. Short to ground should also be checked between each terminal and the injector body.

If any injector is open or short circuit then the item must be replaced. A fully serviced / exchange / new item should be available at your local Diesel Centre, who can also provide “on bench” diagnostic and repair for unit injectors.

Tools & Equipment

Part Number | Description | Operation |

PEM1003 | Inteliprobe Kit | Interchangeable probes which permit wider range of testing |

PEM1000 | Terminal Tool Kit | For removing vehicle computer connectors and terminals. |

PEM1013 | Automotive Multimeter | Testing of voltages and resistance |

Visit our Technician Library for access to Documents and Downloads

Get in touch

Find out where to buy Delphi parts