Safety precautions

EVs and hybrid vehicles contain high-voltage components. If you’re replacing a compressor, you need the right accreditation and follow the necessary safety precautions to the letter.

Air conditioning maintenance is crucial for a vehicle's comfort, safety, and longevity, especially when it comes to EVs and hybrid vehicles. A well-maintained car air conditioning system ensures that drivers and passengers stay cool and comfortable, even on the hottest days. A correctly functioning AC system also helps maintain the best possible cabin air quality, protecting health and wellbeing.

AC is an absolute necessity on modern high voltage vehicles. In hot conditions, air conditioning is often used to cool the battery, especially during driving, charging and fast charging. Without it, vehicle performance can be reduced, along with battery lifespan and performance.

For EVs and hybrids, regular AC servicing is therefore even more important. Additionally, these systems often rely on additional components to combustion engine vehicles. Regular servicing keeps the system running efficiently, prolonging its life and preventing costly repairs later on.

A car air conditioning (AC) system works using a series of components to cool and dehumidify the air inside your vehicle. By compressing, cooling, and evaporating refrigerant, the system effectively regulates the environment inside the vehicle.

There are four primary components in a car AC system, and here’s how they work:

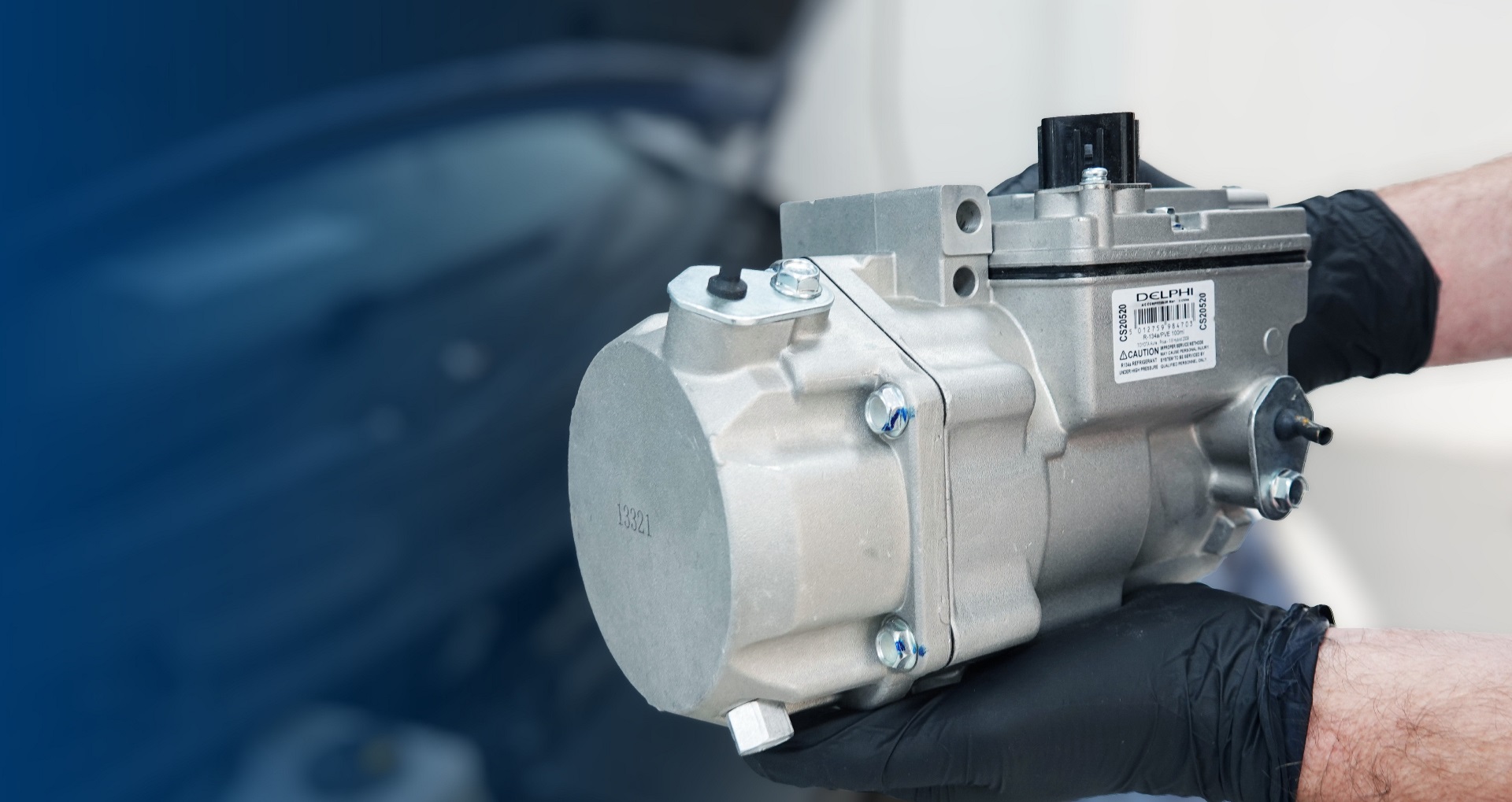

Compressor - the compressor is the heart of the AC system. It compresses the refrigerant, a fluid that absorbs heat. This turns it into a high-pressure, high-temperature gas.

Condenser - once the refrigerant is compressed, it moves into the condenser. The role of the condenser is to cool the refrigerant gas by releasing the heat it carries to the outside air. As the gas cools, it condenses into a high-pressure liquid, ready to continue through the system.

Evaporator - cooled refrigerant then flows into the evaporator. Here, it absorbs heat from the air inside the car. As it does so, the refrigerant evaporates, turning back into a gas. This lowers the air temperature inside the car, providing you with cool, comfortable air. The evaporator also removes moisture from the air reducing cabin humidity.

Refrigerant flow - the refrigerant, now a low-pressure gas, flows back to the compressor, and the cycle repeats. A continuous flow of refrigerant through the AC system is what keeps the air inside a vehicle cool and dry.

Regular maintenance is key to keeping these components in top condition, ensuring your car stays comfortable no matter the weather outside.

While both EV, hybrid and combustion engine air conditioning systems serve the same purpose – to cool and dehumidify the cabin - they differ primarily in how they’re powered and managed. EVs and hybrids use electric compressors, powered directly by the vehicle's battery, making the component more energy-efficient and capable of operating even when the engine is turned off.

EVs and hybrids are optimised for energy efficiency, and often have dual systems for managing both cabin comfort and battery temperature. Being able to maintain AC functionality even in electric-only mode is one of the key advantages of EV and hybrid systems, which makes them more versatile and energy-efficient compared to traditional vehicles.

EV and hybrid air conditioning systems differ in some important other ways too.

What’s the difference between AC compressors for combustion and EV vehicles?

EV and hybrid car batteries each contain hundreds of volts. This adds an extra layer of complexity, so before you begin any AC service, you need to take extra precautions. For example, you must power down the system to reduce any risk of electric shock when working in or around the electric compressor. For this reason, we strongly recommend that you hold an approved hybrid/electric vehicle accreditation before working on high voltage vehicles.

Most modern hybrid and electric vehicles now use fully electric air conditioning compressors that operate independently of the engine. These typically use a brushless motor integrated directly into the compressor housing to drive a scroll-type compression mechanism, which consists of a fixed and an orbiting scroll.

Conventional air conditioning systems typically use PAG or Ester oil. However, EVs and hybrids require a special polyolester (POE) type oil. This has high dieletric or non-conductive properties, that are designed to lubricate the compressor while protecting the compressor’s electrical windings.

Research has shown that as little as one percent of PAG oil in an EV or hybrid system can affect the dielectric properties, reducing the insulation resistance of a compressor from over 10 mega ohms to less than one mega ohm. An impaired winding can damage the compressor, and even shut it down completely because of small voltage leaks that may occur.

For more detail, take a look at our video on how air conditioning compressors for EVs differ from those on combustion engines.

If the air blowing from the car’s vents isn’t as cold as should be, or varies in temperature, it’s a clear sign something isn’t right. In EVs and hybrid cars, this could point to low refrigerant, a failing electric compressor, or even an issue with the battery cooling loop.

Can you hear grinding, clicking, or whining noises when the AC is activated? This could indicate a problem with the electric compressor, blower motor, or internal system debris. Unlike traditional systems, EV and hybrid compressors are electrically driven and can fail silently or with odd electrical noises.

If the air con is unresponsive, there are a number of possible causes: a faulty compressor, a blown fuse or relay in the system, a software or sensor issue, an insulation fault or even oil contamination.

A failing air conditioning system often can’t properly dehumidify the cabin. This results in fogged-up windows, especially in humid or rainy conditions. This might be due to a clogged evaporator, low refrigerant, or even an HVAC control system issue in the vehicle.

Many EVs and hybrids have sensors and diagnostic systems that monitor the air conditioning system. If a ‘check AC system’ message or a warning light appears on the dashboard, the vehicle needs to be scanned at the very least.

If you or your customer notices a musty or sour smell when the AC is on, it's usually a sign of bacteria or mould buildup on the evaporator coil. In EVs and hybrids, this can be more noticeable because the system often runs at lower power or cycles on and off more frequently, creating the perfect conditions for moisture buildup.

In less common cases, a burning or electrical smell could indicate overheating in the electric compressor or an issue with high-voltage components.

Detect issues in the air conditioning system with Delphi's accurate diagnostics tools

To avoid system damage and stay compliant, always start by identifying the manufacturer-specified refrigerant. Check the bonnet label – if it’s missing or unreadable, check the service manual or OEM documentation instead.

Most EVs and hybrids built before 2017 use R-134a, while newer models often use R-1234yf, which is a more environmentally friendly option. But never mix refrigerants – this can damage the system and stop you from completing a full and correct service.

In terms of safe recovery:

Cabin air filter - locate the filter. Remove the cover and slide it out. Check for dirt, debris or smells. If it looks dark or clogged, replace it with a new, manufacturer-approved filter to ensure clean airflow.

Compressor inspection - visually inspect the AC compressor for oil stains, refrigerant residue or physical damage. EV and hybrid compressors are often electric and sealed - so any external signs of leakage or wear mean servicing or replacement is needed.

Electrical connectors - inspect all visible electrical connectors. Look for green or white corrosion, burnt terminals or loose fittings. Clean any light corrosion with an electrical contact cleaner and replace damaged connectors if needed.

Before recharging the air conditioning system, it’s critical to check for leaks - even small ones can lead to performance issues and future component damage. You should do this using oxygen-free nitrogen.

UV Dye Method – if you added UV dye during recharging, use a UV flashlight and yellow safety glasses to inspect the system. Focus on key areas: compressor fittings, condenser joints, service ports and hose connections. Any bright green or yellow glow may indicate a refrigerant leak. Clean the area afterwards to help you monitor for recurring leaks.

Electronic Leak Detector - turn on the electronic refrigerant detector, then slowly move the probe around hoses, fittings, and AC components. The detector will beep or flash when it senses a refrigerant leak. Work slowly and patiently to ensure accuracy.

Important - even tiny leaks can reduce system pressure over time, leading to weakened cooling or compressor failure. Always address leaks immediately to protect system efficiency and avoid the need for repeat servicing.

Start by vacuuming the system. After repairs or leak checks, connect a vacuum pump to the high and low service ports using a manifold gauge set. Run the pump for 30–45 minutes to remove all air and moisture, which can damage components, especially in EV or hybrid electric compressors. Let the system sit for 10–15 minutes to confirm it holds a vacuum.

Next, recharge with the correct refrigerant amount. Add the right refrigerant (see above) via the low-pressure port using a calibrated scale or automated machine for accuracy.

Throughout the recharge, follow these best practices:

We recommend every two years. However, service intervals may vary, so always follow the manufacturer's recommendations in the vehicle’s owner’s manual.

Overcharging can cause high-pressure damage, compressor failure and poor cooling efficiency. Undercharging results in insufficient cooling, increased wear on the compressor, and potentially, system failure. Always charge the system with the exact refrigerant amount specified in the manual.

If you’re removing high-voltage components, you must use the right PPE. It’s also essential you use the correct oil – see our guidance above.

Safety precautions

EVs and hybrid vehicles contain high-voltage components. If you’re replacing a compressor, you need the right accreditation and follow the necessary safety precautions to the letter.

Initial System Inspection

Before beginning, ensure the vehicle is off, especially if inspecting around the compressor.

Inspect Hoses and Connectors - look for cracks, splits or bulges in all visible refrigerant hoses. Gently wiggle connectors to check for looseness, corrosion or oil residue - any oily spots may indicate refrigerant leaks. Pay extra attention to the area around the compressor, condenser and expansion valve connections.

Check for Physical Damage - scan the condenser for bent fins, debris or impact damage. Ensure mounting brackets are secure and nothing is rubbing against hoses or wires. Look at HVAC electrical connectors for burnt, frayed or discoloured wiring.

Start the vehicle with AC on - turn on the vehicle and set the air conditioning to maximum cool and fan speed. Listen for abnormal noises.

Assess airflow and cooling - feel the air from the vents. It should get cold within a minute. Weak airflow could indicate a clogged cabin air filter or motor issue. If air stays warm, the system could be low on refrigerant or have a compressor/electrical fault.

Fill up your details to hear more from our experts and get the latest updates from Delphi.