Heavy duty & off-highway Diesel Fuel Injection

- Product Information

- Product Resources

- Enquire

- Related Products

Rich OE legacy

Our heritage dates back to the legendary CAV brand, and the introduction of in-line and the iconic DPA pump – the best-selling rotary pump worldwide. Both were revolutionary for their time, setting new standards for reliability and power, and we’ve continued to push the boundaries ever since.

Three choices for fleets

By providing three choices – new, reman and repair – we can provide fleet managers with convenient service and maintenance at a very competitive cost.

Latest generation OE technology

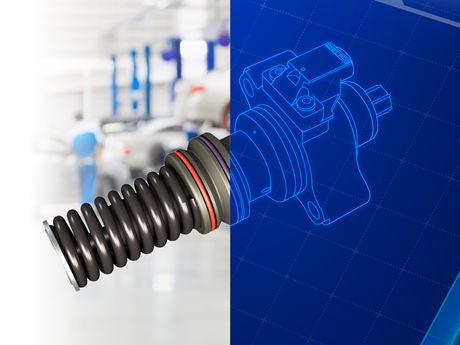

Our latest generation F3 system takes engines beyond the 2021 global emissions and fuel economy regulations and through the next decade. Based on our proven Euro VI Common Rail technology and capable of 3,000 bar injection pressure, it delivers a substantial improvement in emissions, fuel economy and refinement for the lifetime of the engine.

OE-approved repair

In addition to new and remanufactured units, we also offer authorised repair through our global network of Delphi Diesel Centres. Replacing all wearable and performance critical parts, with like-for-like OE, and using OE-approved test plans and equipment, it offers a quality but economical solution.

Find your local diesel specialist here.

Reman

For an equally fast, yet more cost-effective turnaround we offer a range of remanufactured parts. Available off-the-shelf, typically within one to two years of vehicle launch, they are built using OE parts, equipment and processes, and are calibrated to exacting OE specifications.

OE expertise in the aftermarket

Of course, we’re committed to supporting these technologies in the aftermarket. We offer a range of new OE components, identical to those originally fitted, including our pioneering Electronic Unit Injector, Electronic Unit Pump, Smart injector and Multec® Common Rail.

Commercial vehicle diagnostics and test

Our dedicated diagnostic solution for trucks, buses and trailers, supports the key commercial vehicle manufacturers and systems, including the ability to carry out dosing tests, Adblue freeze monitoring calibration, system drain down and regeneration of the SCR system. We also offer a range of OE-approved test equipment for quick and accurate test and repair of the latest heavy duty applications.

Training from the OE experts

Designed to help you prepare for the very latest heavy duty diesel fuel injection technologies, our extensive training programme covers the repair of key systems, including Electronic Unit Injector and Pump and Smart injectors. Learn more about our training.

.jpg?sfvrsn=950636e0_7)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, you will find out more about Delphi OE quality guaranteed products.

Quality! Everyone says they have it. Some do. Some don’t. Others have to varying degrees. So how, as an aftermarket professional, are you supposed to cut through all the talk and determine what’s genuine quality, versus just words…?

Simple! When it comes to automotive, there’s no better endorsement than a vehicle manufacturer (VM) choosing to fit your product. After all, to be selected in the first place involves a rigorous process - often years of development and close collaboration - to engineer a product that meets every one of the VM's demanding standards. Whether that’s stopping sooner, accelerating quicker or making cleaner, more efficient vehicles that drive better. Being the original equipment manufacturer is the holy grail so to speak, and something which many manufacturers strive for, but ultimately never achieve.

The good news is we have! As a leading manufacturer of OE propulsion technology our diesel, GDi, engine management and ignition parts are fitted as OE to millions of vehicles worldwide. Importantly for you, we supply these very same parts into the aftermarket - the part you receive, is the same part that is fitted by the vehicle manufacturer. We don’t change the spec simply because it’s for a different customer. Or the expectations may be slightly different. On the contrary, we believe what’s right for the vehicle owner when they drive the car off the dealership forecourt, is still right when they come to service it, even if that’s years later.

Equally importantly, we apply these same principles to everything else we do. So whether it’s designed for the assembly line or the garage bay, our processes are just as rigorous. Every part undergoes the same demanding dimension, material, durability and performance tests. No matter what it is, where it’s made, or indeed who it’s for.

Take our brake discs as an example. Unlike some other aftermarket brands, the vanes in our vented discs are constructed exactly as the OE part with the parting line in centre. Whilst this is more complicated and costlier to cast, it provides much better braking balance and resistance to cracking. Which is why we do it too.

Same goes for our brake pads. We use over 130 different friction ingredients to create unique friction formulations for the best possible match of brake pad to vehicle. Again, some other manufacturers use only one or two, resulting in an inevitable compromise in performance.

Of course, all this is meaningless if the part doesn’t deliver when it needs to. To replicate the conditions it will experience on the road, we conduct real world testing on all our products. For example, we test our wishbones on all three axes – side-to-side movement, forward force from acceleration and deceleration and up and down movement - at the same time. And we subject our sensors to extensive thermal, shock and vibration testing. It goes without saying that the Delphi part must perform as well as the OE component, if not better.

These are just a few examples of our all-encompassing approach to achieving the very highest OE quality standards. We could go on. The important point is, that when you buy a Delphi’ part – be it braking, steering, air conditioning, fuel injection, ignition, engine management or even the equipment needed to diagnose and repair them - you get the same guaranteed, long-lasting OE quality. Every single time.

Get in touch

Find out where to buy Delphi parts