Heavy duty & off-highway Diesel Fuel Injection

- Product Information

- Product Resources

- Enquire

- Related Products

Rich OE legacy

Our heritage dates back to the legendary CAV brand, and the introduction of in-line and the iconic DPA pump – the best-selling rotary pump worldwide. Both were revolutionary for their time, setting new standards for reliability and power, and we’ve continued to push the boundaries ever since.

Three choices for fleets

By providing three choices – new, reman and repair – we can provide fleet managers with convenient service and maintenance at a very competitive cost.

Latest generation OE technology

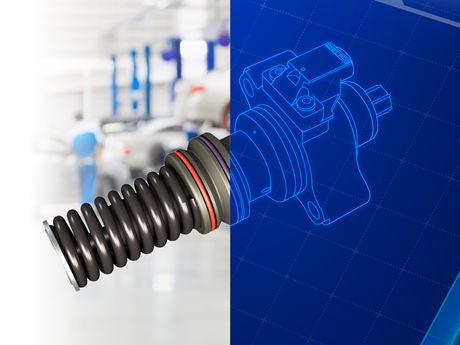

Our latest generation F3 system takes engines beyond the 2021 global emissions and fuel economy regulations and through the next decade. Based on our proven Euro VI Common Rail technology and capable of 3,000 bar injection pressure, it delivers a substantial improvement in emissions, fuel economy and refinement for the lifetime of the engine.

OE-approved repair

In addition to new and remanufactured units, we also offer authorised repair through our global network of Delphi Diesel Centres. Replacing all wearable and performance critical parts, with like-for-like OE, and using OE-approved test plans and equipment, it offers a quality but economical solution.

Find your local diesel specialist here.

Reman

For an equally fast, yet more cost-effective turnaround we offer a range of remanufactured parts. Available off-the-shelf, typically within one to two years of vehicle launch, they are built using OE parts, equipment and processes, and are calibrated to exacting OE specifications.

OE expertise in the aftermarket

Of course, we’re committed to supporting these technologies in the aftermarket. We offer a range of new OE components, identical to those originally fitted, including our pioneering Electronic Unit Injector, Electronic Unit Pump, Smart injector and Multec® Common Rail.

Commercial vehicle diagnostics and test

Our dedicated diagnostic solution for trucks, buses and trailers, supports the key commercial vehicle manufacturers and systems, including the ability to carry out dosing tests, Adblue freeze monitoring calibration, system drain down and regeneration of the SCR system. We also offer a range of OE-approved test equipment for quick and accurate test and repair of the latest heavy duty applications.

Training from the OE experts

Designed to help you prepare for the very latest heavy duty diesel fuel injection technologies, our extensive training programme covers the repair of key systems, including Electronic Unit Injector and Pump and Smart injectors. Learn more about our training.

.jpg?sfvrsn=950636e0_7)

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

A diesel particulate filter (DPF) pressure sensor is designed to measure exhaust backpressure and then let the power-train control module (PCM) know when the filter needs to be cleaned by performing regeneration.

Our Delphi expert shares how to recalibrate learn values after replacing a DPF pressure sensor. Discover all this:

- The importance of a DPF pressure sensor

- How to perform the recalibration

- How to produce a calibration certificate

Why does the DPF sensor need to be calibrated?

If a replaced DPF pressure sensor is not calibrated properly, regeneration may not be carried out when needed and the vehicle’s performance is affected.

What is regeneration of the filter?

This is the periodic cleaning of the DPF filter by burning off soot that accumulates.

What information will I need?

To perform the calibration, you will need either the vehicle registration or VIN number. You will need to input the information into the tablet that comes with your Delphi diagnostic kit.

Why do I need a certificate?

This is proof that you have correctly calibrated the DPF sensor. You can print this out to give to your customer, as well as keep a PDF copy for your own records.

Get in touch

Find out where to buy Delphi parts