Mass Air Flow Sensors

- Product Information

- Product Resources

- Enquire

- Related Products

Innovative OE design

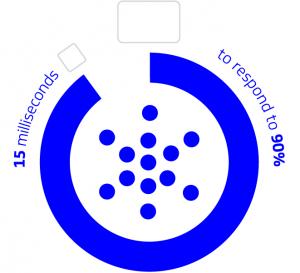

We build our OE expertise into every MAF sensor we make. Featuring a proprietary temperature compensation design, they offer outstanding performance over a wide range of ambient temperatures. And are fast to respond to changing engine conditions – typically less than 15 milliseconds to respond to 90 percent of a flow change. Innovative, dual-heated elements on specific references also help to ensure optimal performance, fuel efficiency, and reduced emissions

OE engineered and tested

By testing and calibrating to OE specifications, our MAF sensors provide the same accurate readings and airflow output as the OE. Each sensor is tested on state-of-the-art sonic nozzle-testing equipment capturing over 6,000 data points per flow, for optimal calibration accuracy. They’re also flow tested to match the OE for signal stability (noise), temperature compensation (the ability of the MAF sensor to measure airflow accurately from -30°C to 70°C) and electromagnetic compatibility.

Never remanufactured MAF sensor

Some things are better new. That’s why every sensor we make – whether with or without the housing—is built with all-new components and never remanufactured. Remanufactured MAFs are simply cleaned and tested, so any contamination on the sensor may not be eliminated, resulting in inaccurate readings to the ECU.

Greener probe-only technology

It’s often the electronics on the sensor probe that fail, meaning it’s not always necessary to replace the complete part. So we developed a probe-only solution, in addition to a full range of complete units. By eliminating the plastic housing, this provides a greener, more cost-effective and faster repair option.

The complete package

With Delphi you get access to the complete package: the range, advanced DS diagnostics including the ability to look at live data, both at idle and max RPM, to determine if the MAF sensor is reporting the correct data, expert training and support and vehicle technical information including wiring diagrams, component locations and guided diagnostic procedures.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

The crankshaft sensor is an important piece of kit to keep the engine running correctly. On this page we’ll highlight common causes of crankshaft sensor failure, why it happens and how to fix it.

What is a crankshaft sensor and what does it do?

A vehicle’s crankshaft sensor or CKP sensor contributes to the precision timing of a finely tuned engine. It monitors the position and rotational speed of the crankshaft, so the engine control unit (ECU) can adjust its calculations in the fuel injection timing and elsewhere.

The crankshaft’s speed and position must be closely monitored to properly maintain a four-stroke engine. Without this input from the sensor, the engine may not even start. Therefore, the sensor output is an essential part of the process.

What causes a crankshaft sensor to go bad?

There are several factors which can cause a crankshaft sensor to fail. • In crankshaft sensors which contain magnets, a build-up of dirt on the magnet can block the sensor and prevent it from seeing the engine’s spin.

- Crankshaft sensor age – the magnet in the sensor loses its pull over time, which means it grows less capable of providing accurate signals to the ECU.

- Faulty, lose or damaged wiring can affect the sensor’s ability to send signals accurately to the ECU.

- Sensor damage resulting from being hit from another component inside the engine such as the crankshaft pickup, or by road debris.

- Damage to components that the crankshaft sensor is monitoring. This will essentially confuse the sensor, as the damaged components would send mixed signals. This will likely bring up an engine check light.

Find crankshaft position sensors and a selection of OE parts in the Delphi online catalogue

What are the symptoms of a bad crankshaft sensor?

A vehicle diagnosed as having a faulty crankshaft sensor is likely to exhibit a number of problems with the engine and overall performance. Look for the following warning signs to confirm what’s troubling the vehicle.

1. ‘Check engine’ light is showing

(Note: If the vehicle has a camshaft sensor you might not get an engine warning light, and no fault on the diagnostic tool. The ECU doesn’t know if the engine is specifically not starting, or is just at rest. Check the RPM to be sure. Newer cars have two camshaft sensors so they should be able to see if the camshaft has an issue.)

If the sensor isn’t relaying information to the ECU, or what it is sending appears troubling, the ECU will respond by turning on the engine light – your cue to assess what’s wrong with the vehicle. The engine light could be caused by a range of different issues aside from the crankshaft sensor. A diagnostic tool can help you to identify if the sensor is the part that’s causing concern.

2. Engine is having trouble starting

The crankshaft sensor is responsible for keeping a close eye on the position and speed of the crankshaft when starting the engine. So if it’s unable to relay information back to the ECU, the engine may not start. If the engine is currently running, you may not even notice an issue here regardless of whether or not there’s an engine light – the sensor uses an algorithm to estimate where the crank has spun to based on previous knowledge, so the engine won’t shut off due to electronic override. It’s only when you key off the engine and try to restart the vehicle later that an issue will occur.

3. Limp mode

A bad crankshaft sensor isn’t the only reason a vehicle may experience higher than usual fuel consumption, but it’s nonetheless one of the tell-tale signs. With a faulty crankshaft sensor, the engine may go into limp mode if it’s still running. This means the fuel injectors won’t act as efficiently in their role, meaning reduced performance and an overall worse fuel economy.

4. Acceleration is uneven or unsteady

The engine relies on the crankshaft position sensor for correct signals to properly manage fuel injection. With mixed or no signals, acceleration may be weak or unresponsive.

5. Engine is misfiring or vibrating

Without the right information about the position of the pistons, the engine may misfire. When idle, the vehicle may also experience shaking and sometimes refuse to start at all, especially if the engine is cold.

6. High fuel consumption

Because the fuel injection process will be hampered by receiving incorrect signals from a faulty crankshaft sensor, the fuel may not combust in the engine properly. Not only can this cause the engine to sputter, but also reduce power. This leads to more fuel being consumed to achieve the same performance.

Find crankshaft position sensors and a selection of OE parts in the Delphi online catalogue

What happens if you drive with a bad crankshaft sensor?

If a crankshaft sensor develops an issue while the engine is running, although a specific fault may cause engine misfire, there won’t necessarily be a problem. It may go into limp mode while driving, to reduce the chances of further damage. However, if the engine is not running, the vehicle may not start at all.

What to do if a crankshaft sensor is faulty?

If a faulty crankshaft sensor is suspected, or a similar issue is causing engine problems, an inspection will be required. The sensor should be tested for faults – this can be done with both a visual inspection and using an oscilloscope.

If there is an issue with the sensor, we’d recommend replacing the part entirely. It’s a relatively simple job – locate the sensor (usually close to the flywheel or on the timing cover side of the block), remove electrical connections and replace with a new part.

Suffering from a faulty crankshaft sensor?

Once it’s stopped, a vehicle with a bad crankshaft sensor is unlikely to get going again. Having checked the symptoms of a faulty crankshaft sensor against other potential causes, the recommended course of action is to carry out a replacement. Delphi stocks crankshaft position sensors as well as other OE car parts – check out the range today.

Get in touch

The full Delphi Sensors product range

Find out where to buy Delphi parts