Sabre CRi Expert

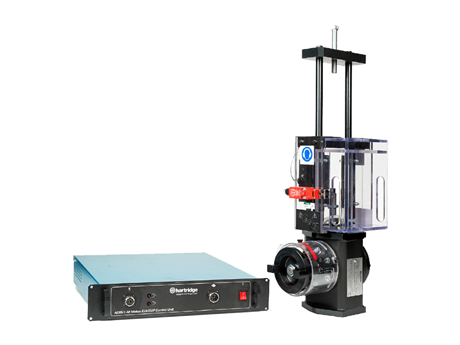

The new Sabre CRi Expert is a progression of the Sabre platform. The Expert model isn't replacing the Master model, but instead opens up other opportunities for a workshop to advance and grow on a platform which is centered on easy use throughout.

- Product Information

- Product Resources

- Enquire

- Related Products

Future Ready Testing

A number of components within this award winning, compact platform are unique to the Sabre CRi Expert, setting it apart while retaining its roots as a firm workshop favorite. New features and functions have been engineered from the ground up to provide a future ready testing solution that stays ahead of the market.

New Software Developed

Hartridge has developed brand new, next generation magmah software for the Sabre CRi platform. The magmah Touch software is so intuitive that even a brand new user can achieve a superior level of injector testing. The software shows the technician dynamic, real-time testing, on-board machine diagnostics, and new test plan tools. Thanks to unprecedented levels of customization for the workshop, the magmah Touch software can evolve as the business evolves. The magmah Touch license is completely free and fully supported for the lifetime of the machine.

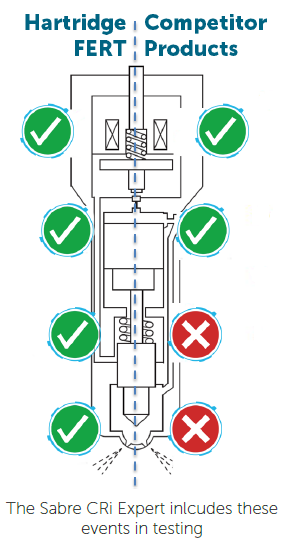

Full Event Response Time (FERT)

Unlike other methods of measuring injector response time which only monitor electrical signals to determine solenoid actuation, Hartridge measures the full event. FERT includes all internal elements of the injector to give you a complete view of the response time of the injector from electrical activation to the injection event.

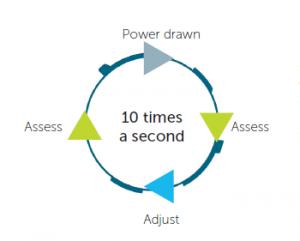

Patented Closed-Loop Technology

The Sabre CRi platform's unique, patented Closed-Loop technology constantly monitors the power used by the internal pump 10 times per second. This makes sure the Sabre's operation remains stable, and that full power of the pump is available to maximize flow output at high rail pressures. Not only does it ensure that the power draw is constantly balanced, but it means the Sabre can be powered by domestic power supplies making installation and use in the workshop straightforward and instant.

Advanced Test Steps

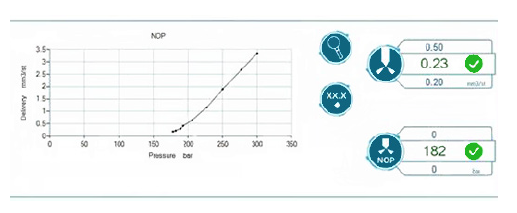

Built into the software are a number of additional test steps to offer further levels of expert diagnostics for the latest high pressure applications. Nozzle Opening Pressure (NOP) checks for correct mechanical function of the nozzle to open at the required pressure to achieve the intended atomization.

Minimum Drive Pulse (MDP) is a dynamic delivery sweep test that provides the MDP measurement and also the ability to determine the profile of the delivery curve thanks to the new graph functions implemented into the magmah Touch software.

Specific testing has also been developed for the new internal pressure sensor in Denso's latest injector technology, i-ART, measuring the fluctuations of pressure to ensure accurate testing. Thanks to these enhanced features the workshop can offer a wider range of services.

Injector Coding

Hartridge coding is derived from our rigorous testing development process to generate coding with validated parameters. For easy and fast testing in the workshop the software locks in the mandatory test steps required to generate coding for that injector. The resulting code is a part of test results document which can be saved in the software.

Test Plans

We have applied our decades of experience with OE test plan creation processes to develop test plans with validated limits for all test conditions. A full test is fast, typically around 5-6 minutes for a standard test. If advanced steps are added, the time will increase by approximately 1 minute per step. There are various testing modes which make testing straight forward for a new user or more customizable for advanced use. Many test plans are provided unlocked on the machine. Additional test plans and steps are purchased with the credit system.

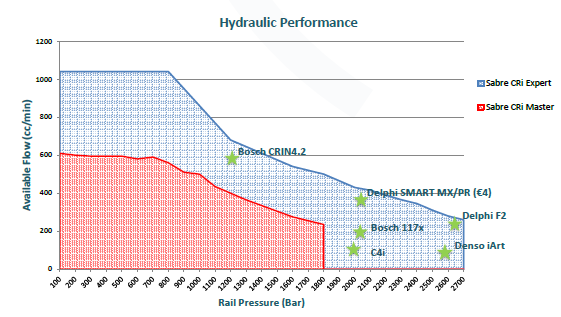

High Pressure Capability

The powerful pump and rail within this compact solution generates 2700 bar. A range of unique features provide stable performance at high pressure. As a result the available flow also allows for testing injectors that require high flow, but not high pressure. The Sabre CRi Expert is capable of testing upcoming high pressure injectors including Euro 6/US10 heavy duty Delphi F2x injectors, Euro 4/US07 Delphi Smart injectors, Bosch 117 family, Bosch CRIN twin coil injectors, and Denso i-ART. The workshop can be ready for the future of injection technology and maximize the return on investment.

Smarter Licensing

The Sabre CRi Expert is now more flexible than ever with new pay-as-you-go functionality. The workshop can now unlock functions, test steps, and coding only when they need to and do not need to pay for functionality they wouldn't use. The uploading of credit bundles is secure and unique to your machine, ensuring the user has a ready supply of credits to unlock functions as needed and maintain smooth operation in the workshop.

Installation Requirements

Two domestic electrical mains connections are required:

- Machine input: 100-120 Vac, or 200-240 Vac, 50/60 Hz (either supply must be capable of 10amps)

- Motor input: 200-240 Vac, 50/60 Hz (15 amps)

You must use Viscor 1487-AW2 (Hartridge 8802011) or equivalent calibration fluid with the protected Antiwear 2 properties. Dimensions are 610mm (W), 610mm (D), and 1100mm (H). The machine weighs 145 kg unladen.

Injector Measurements

Coil resistance | 0-200 Ω |

Inductance (coil injectors only) | 0-20 mH |

Capacitance (piezo injectors) | 0-12 µF |

Response time measurements | 0-999 µS |

Backleak flow measurements | 0-1100 mL/min |

Delivery measurements | 0.2-400 mm3/str |

Backleak temperature | 0-180 degrees Celsius |

Technical Specification

Rail pressure | 1-2700 bar |

Injection speed | 120-3000 inj/m |

Pulse width | 0-4000 μS |

Time delay | 0-600 seconds |

Tank capacity | 10 liters |

Tank filtration | 2 µm |

Metering unit filtration | 60 µm |

Backleak filtration | 60 µm (Sabre CRi Expert + HJ092) 7 µm (Sabre CRi Expert - HJ092) |

High pressure flow | 1050-250 cc/min |

Fluid cooling | Air-to-oil heat exchangers |

Coil drive | Twin coil |

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Test Equipment (Hartridge) product range

Contact Us

Visit our Contact hub to find a range of enquiry types suited to help you find the exact support you are looking for.