Resource Highlights

In this article, you will find out about Hard or non-start problems due to fuel injection system.

Summary

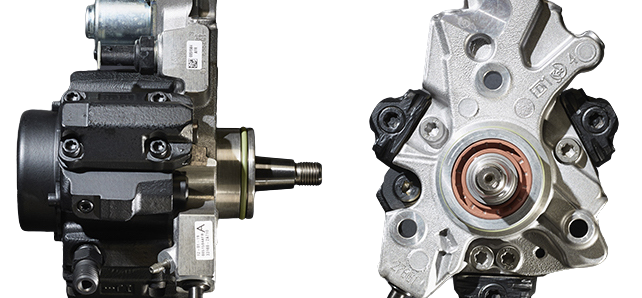

Some 2.0 HDi vehicles may develop hard or non-start problems which can be attributed to the fuel injection system.

This may be due to failures in either the low pressure feed to the high pressure pump, or the high pressure pump itself.

Resolution

The fault codes should be first read using the DS diagnostic kit and if pressure related faults are recorded the following process will aid repair.

For the low pressure system a feed pressure of at least 2.5 bar is required at the high pressure pump inlet. This can be measured with a low pressure gauge on a “T” connector fixed to the HP pump inlet under cranking conditions.

If the pressure is low or non-existent then the low pressure system must be repaired first. Common reasons for failure are:

- Blocked fuel filter / fuel contamination

- Failure or blockage of the low pressure supply pump

- Wiring issues to the low pressure pump

If the reason for failure is fuel contamination then the whole system must be cleaned out, and this may include major service of the high pressure components as well.

If adequate pressure is available from the low pressure circuit then the high pressure circuit should be checked for efficiency. A minimum pressure of 117bar is required to affect an engine start. This can be checked through the diagnostic port and by reviewing the dynamic data referring to rail pressure.

It may be possible that the data supplied is inaccurate due to a failure of the rail pressure sensor, but not necessarily creating a rail pressure sensor fault code in the process. It is also possible that low pressure is attributable to a leak in the system which is not visually detectable.

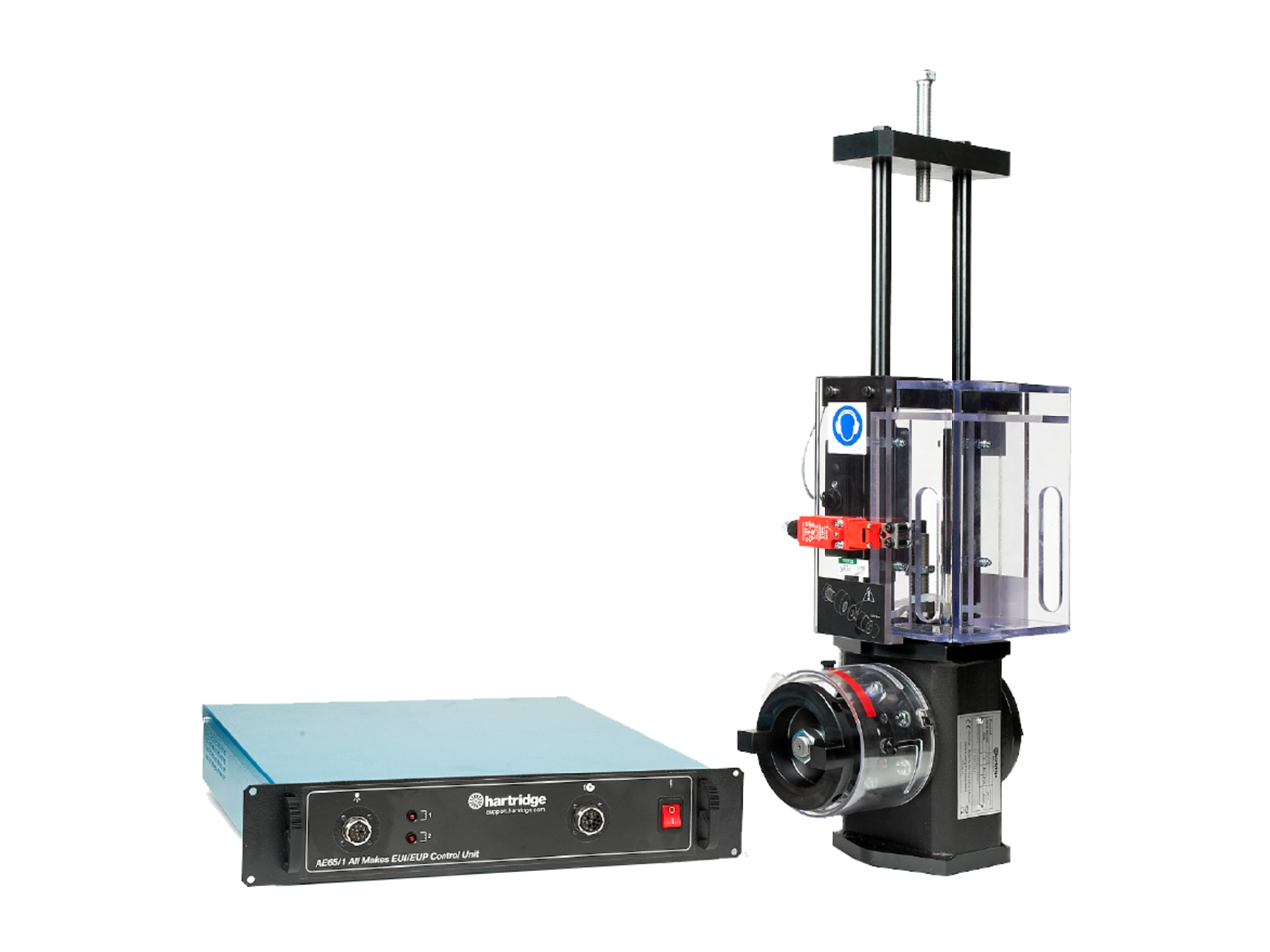

In order to confirm the high pressure pump efficiency in a ‘stand alone’ condition the Delphi sealed rail kit (YDT278) can be used to determine the pumping efficiency of the high pressure pump. If a pressure issue is found on the pump, then this is a serviceable item via the local Diesel Centre or Technical Partner. Note the pressure parameters in the information pack supplied with the sealed rail kit.

If the pump sealed rail test is okay then further investigation into possible leakage via the rail, high pressure valve, or injectors will be necessary. For Injectors a back leakage check using the sealed rail kit is possible, and again these are serviceable items via the Technical Partner.

If both low and high pressure requirements are met, poor and non-start situations should be avoided.

Tools & Equipment

|

Part Number |

Description |

Operation |

|

DS100 |

Diagnostic tool |

Fault code reader |

|

YDT278 |

Sealed Rail Kit |

Check HP pump pressure and backleak of injectors |

Related article resources and products

Contact Us

Visit our Contact hub to find a range of enquiry types suited to help you find the exact support you are looking for.