For decades now western manufacturers have dominated the European market. On any road, chances are you’ll see a Ford Focus, VW Golf, or Renault Clio. However thanks to the rapid growth of Asian brands such as Toyota, Hyundai, and Kia that picture is changing. And with it, a new range of vehicles are emerging, presenting new opportunities for both specialist and multi-brand garages fitting high-quality products. Here we explain what’s driving this growth? And how you can take advantage of the opportunity with our newly extended braking range for Asian applications….

Whilst Japanese brands have long ranked amongst the world’s top vehicle manufacturers, it's only in the last decade that their South Korean counterparts can be considered in the same league. Once deemed poor quality and cheap, Hyundai and Kia are fast gaining ground on their rivals, driven by a steadfast commitment to quality, industry-leading warranties, and value for money.

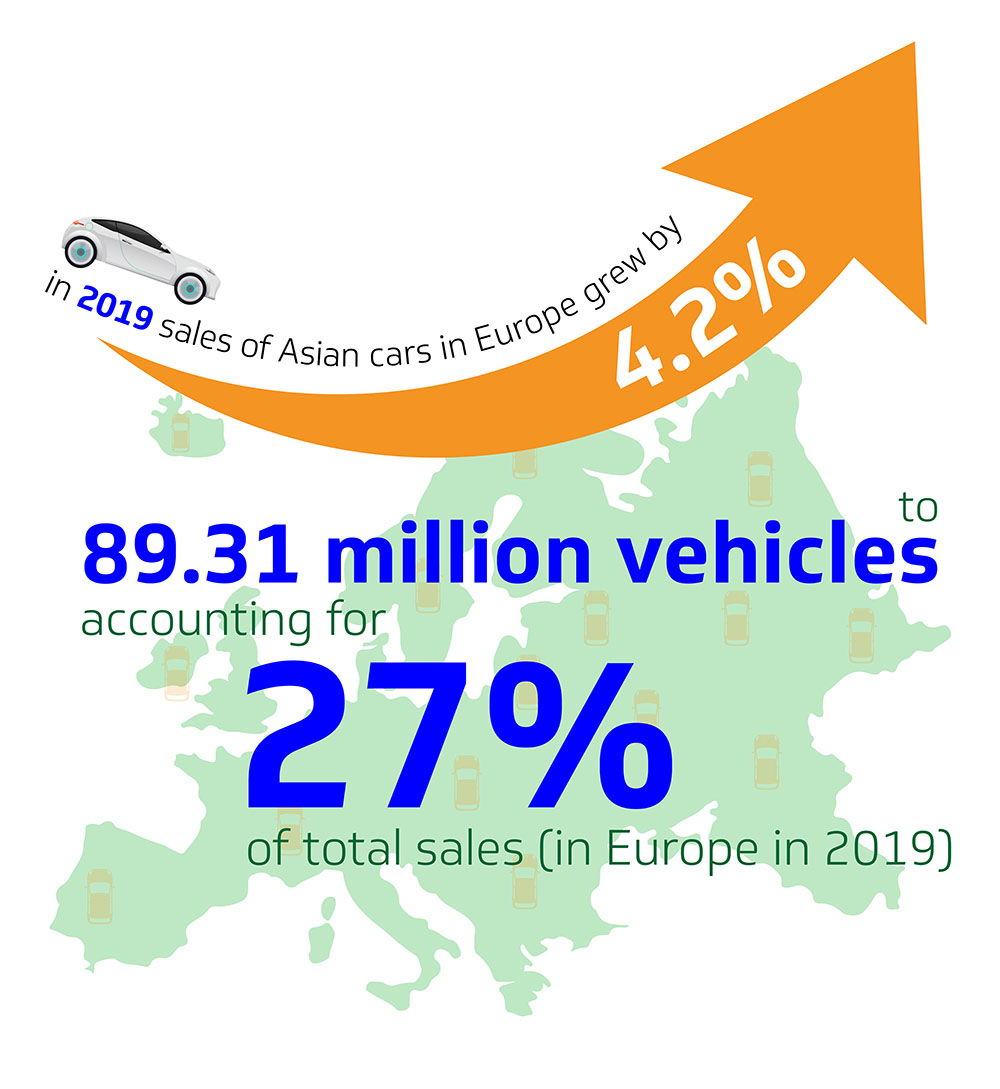

The growing acceptance of Korean brands, together with already established Japanese marques like Toyota, Honda, and Nissan, means that Asian manufacturers are now making significant inroads into the European market. Indeed, in 2019, sales of Asian cars in Europe grew by 4.2% percent to 89.31 million vehicles, accounting for 27 percent of total sales (in Europe in 2019).

A growing service opportunity

This can only be a good thing for the aftermarket. In the last five years alone 20 million Asian cars have been added to Europe’s road. With a parc now approaching 90 million, rising to more than 100 million by 2023, it is inevitable that you will see more and more of these vehicles in your garage needing high-quality repairs.

To meet the rapidly growing demand for replacement parts, we’ve recently extended our braking line-up for Japanese and Korean applications. The expanded range includes 2,600 braking components fitted to popular vehicles such as Mazda 3 (01/19>), Hyundai i30 Fastback (11/18>), Nissan Qashqai (04/19>) and Toyota Corolla (02/19>) and Supra (06/19>), one of our many first-to-market applications. With these introductions and more, we now cover over 99 percent of the European parc on pads and 97.7 percent on discs…..a number which will only continue to grow as we add to the range throughout 2020 and beyond.

A quality vehicle demands a quality part

In a 2018 study by JD Power, which measures the number of problems per 100 vehicles during the first 90 days of ownership, Asian vehicles ranked highly; Kia, Hyundai, and its luxury brand Genesis, topped the manufacturer's list with the fewest problems. Toyota Corolla was named as the best ranked compact car, Kia Sorrento the best mid-sized SUV, Nissan Altima for mid-sized cars, and Hyundai Tuscan for small SUVs. It goes without saying that owners will expect the same high standards throughout the vehicle’s lifetime. Which is why quality is at the forefront of everything we do too.

Just like the rest of our braking line-up, all our components for Asian applications are designed, engineered, and manufactured to mirror the OE. Every one of our pads, for example, features a special OE underlayer technology, which absorbs noise, reduces heat transfer, and increases the pad’s shear strength. Not all our competitors fit this as standard. And our discs are manufactured using a range of different castings and/or configurations, again, as per the OE. So, if the OE is made from high-carbon cast iron and coated. So is ours. If it’s vented for improved cooling capacity. So is ours. You get the gist! Whatever it is, we match it.

So, the next time you have a Korean, Japanese, or any other brand come to that, on your ramp, think Delphi Technologies – for a proven OE-quality part that you can fit with confidence. Every single time.