Ball Joints

If you're hearing a noise from your car, hoping it may be from the car next to you, you may be due for an OE quality ball joint replacement. Delphi can give you the smooth, strong and high-quality fix that you need.

Why should you trust Delphi for ball joints?

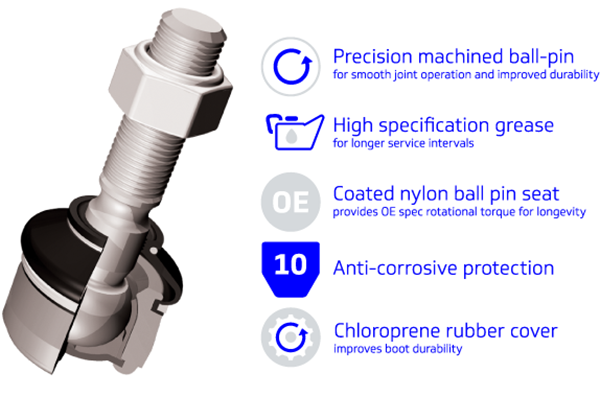

- Manufactured with high-quality forgings for increased strength and smooth operation.

- Chloroprene rubber boot improves durability and prevents premature failure, with cover to protect internal components.

- Machined to micron tolerances to guarantee durability and smooth joint operation.

- Anti-corrosion protection applied to each part.

- Ball-pin 100% crack tested for flaw free material.

- Undergo rigorous performance and resilience tests.

- Superior ball-pin finish and nylon seat coating for smooth movement and long lifetime.

- High specification grease for reduced friction, and smooth operation in all temperatures and conditions.

What does a ball joint do?

Think of the ball joint like a human hip joint. It acts as a pivot between the vehicle’s wheels and suspension, allowing the vehicle to be steered while ensuring a comfortable ride.

Why does a ball joint fail?

The ball joint’s constant motion subjects it to significant stress and wear. If it is worn out or its rubber boot splits or cracks, it needs to be replaced. So, you’ll want to fit a high-quality ball joint that has been designed, engineered and manufactured to the same standards as OE. Make sure to replace the entire ball joint and not just the ball joint boot. A damaged boot can let in contaminants that could corrode and/or impact the smooth feel of the ball joint. It can also lose grease lubricant, which is intended to last the life of the joint, causing significant friction and possible sticking.

Learn more about ball joint failure symptoms.

Precision engineering

Enabling free movement in two planes at the same time, the ball-pin is a critical component. That’s why our ball-pins are manufactured from high-grade steel and machined to micron tolerances. Together with a polyoxymethylene nylon ball-pin seat, they provide optimum durability and smooth joint operation.

Extensive testing

Delphi ball joints undergo rigorous performance tests including angular stress testing, where the ball is rotated through its angular and rotational travel under load, as well as a pull and push out test, to measure the force required for it to break away from the housing. These important safety tests ensure the ball joint can withstand the same forces as the OE part.

Cataphoretic coating

Like many of our steering parts, Delphi ball joints feature an environmentally friendly cataphoretic coating for tougher and longer lasting protection from corrosion caused by salt, dirt and water and other contaminants.

Greater protection

To help prevent damage to the joint’s internal components, all our ball joints come with a special chloroprene rubber cover. The new and improved formula maintains its durability even in extreme temperatures, providing added protection from road dirt or salt and allowing continued free movement of the ball joint for a longer lasting par

Longer service intervals

We provide a range of sealed ball joints, that are lubed for life with a high-specification grease, to minimize maintenance requirements. Alongside our precision ball-pin finish and improved rubber boot design, they offer longer ball joint service intervals and better grease retention.

Click here to view our catalog

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Steering & Suspension Sell Sheet

- Steering & Suspension

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Chassis product range

Contact Us

Visit our Contact hub to find a range of enquiry types suited to help you find the exact support you are looking for.

Leave a comment