YDT-35

- Product Information

- Product Resources

- Enquire

- Related Products

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

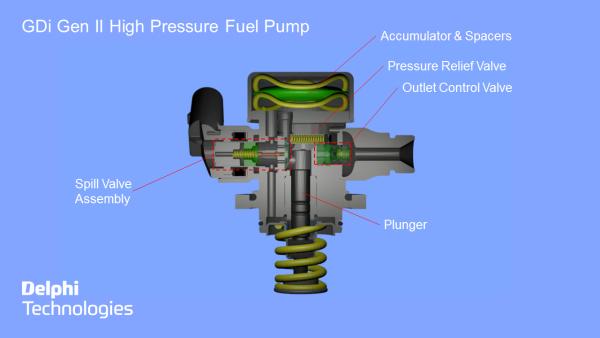

In this article you will find out about the basics of GDi and understand the common GDI service issues.

Basics of GDi

Despite making its debut in the mid 1950’s, Gasoline Direction Injection (GDi) has only recently come into its own, as vehicle manufacturers look for more meaningful ways to meet increasingly stringent emissions standards.

By injecting fuel at high pressure directly into the combustion chamber, the innovative system improves fuel atomization and penetration, delivering reduced CO2 emissions, improved fuel economy and better engine performance.

So why has a technology with so many good things going for it not been adopted sooner? The simple truth, is that like many things, there are pros and cons. And for GDi, that also means a number of common service related issues such as carbon build up, oil vaporization and low speed pre-ignition.

Understanding common service issues for GDi

Here we explore what these are and, importantly, how we can help you to overcome them.

Fuel dilution: Because the injectors are located in the combustion chamber, fuel spray can wash past the rings, down the far cylinder wall and into the oil sump, contaminating the oil and affecting its viscosity. This can cause issues such as increased wear of pistons, rings and cylinders, reduced protection against deposits, higher oil consumption and quicker oxidation.

Oil vaporisation: The higher temperatures and pressures in GDi engines can accelerate oil vaporization. Oil vapors passing through the cooler areas of the engine such as the intake valves, piston crown and catalytic system can lead to pooling and the formation of oil droplets. Because, unlike a port fuel injection engine, these droplets are not washed off by the fuel, they can coat and bake onto the valve causing performance issues.

Oil evaporation: The higher temperatures in the crankcase can also cause some of the oil to evaporate, meaning that the fuel can become more concentrated. Much like fuel dilution, this impacts the oil’s viscosity, accelerating wear and tear of key components and reducing the oil’s service life.

Carbon build-up: Again, because fuel no longer reaches and cleans the valves, this can result in a build-up of carbon on both the injectors and valves, restricting fuel delivery and air flow to the cylinders respectively. Over time, these deposits can cause performance issues such as reduced engine power and fuel economy.

Low-speed pre-ignition: Known as LSPI for short, it typically occurs under low speed, high load conditions. LSPI is caused by fuel droplets that are released into the combustion chamber and ignited before the spark plug fires. This abnormal combustion event can result in higher engine pressures, leading to engine knock and potentially severe internal damage.

As these service issues can occur in as little as 3,000 miles, diagnosing and remedying them early is important. Failure to do so will not only affect the vehicle’s performance and fuel economy, but if left untreated for long enough, could also result in severe engine damage, requiring a timely and costly teardown to fix.

The good news is, that as a leading manufacturer of OE GDi technology, we understand the challenges of maintaining and repairing these highly advanced, high pressure systems. And alongside the OE parts, provide the tools and know-how you’ll need to remedy these issues, long before they become a bigger problem.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Hartridge product range

Find out where to buy Delphi parts