Control Arms

Turn to Delphi for steering & suspension. Our control arms and track control arms are the real deal. As a critical element of a vehicle’s design and an integral part of the suspension system, you've got to choose an OE quality control arm. That's why you can turn to Delphi for reliable steering & suspension parts.

Why should you trust Delphi for control arms?

- Our control arms undergo 100% crack detection and ultrasonic flaw detection tests to ensure materials match OE specifications.

- Robot welded for consistent performance and quality.

- Anti-corrosion protection applied to each part.

- We test our parts to the extreme, from every angle, for reliable performance at temperatures below -40°F and over 248°F.

- Product Information

- Product Resources

- Enquire

- Related Products

Turn to Delphi for strong import and domestic coverage

Whether you’re a technician or a DIYer, you can trust Delphi steering & suspension parts for your domestic, European and Asian vehicles. We cover 26 major automotive brands, including late model applications through 2025.

What control arms do:

Help control the motion of the wheels and connect the suspension to the vehicle structure. Connecting the spindle, hub or knuckle and wheel to the vehicle’s chassis, the control arm is a critical part of any vehicle’s steering and suspension system. Also known as an A arm, it allows the wheels to move up and down, while preventing forward and rearward movement and maintaining directional input from the driver. So, when the steering wheel is turned, the wheels follow suit.

When control arms fail:

If a control arm comes loose or is bent, it can be dangerous to drive. This can happen after collisions, hitting pot holes or curbs, etc. Learn more about control arm failure symptoms.

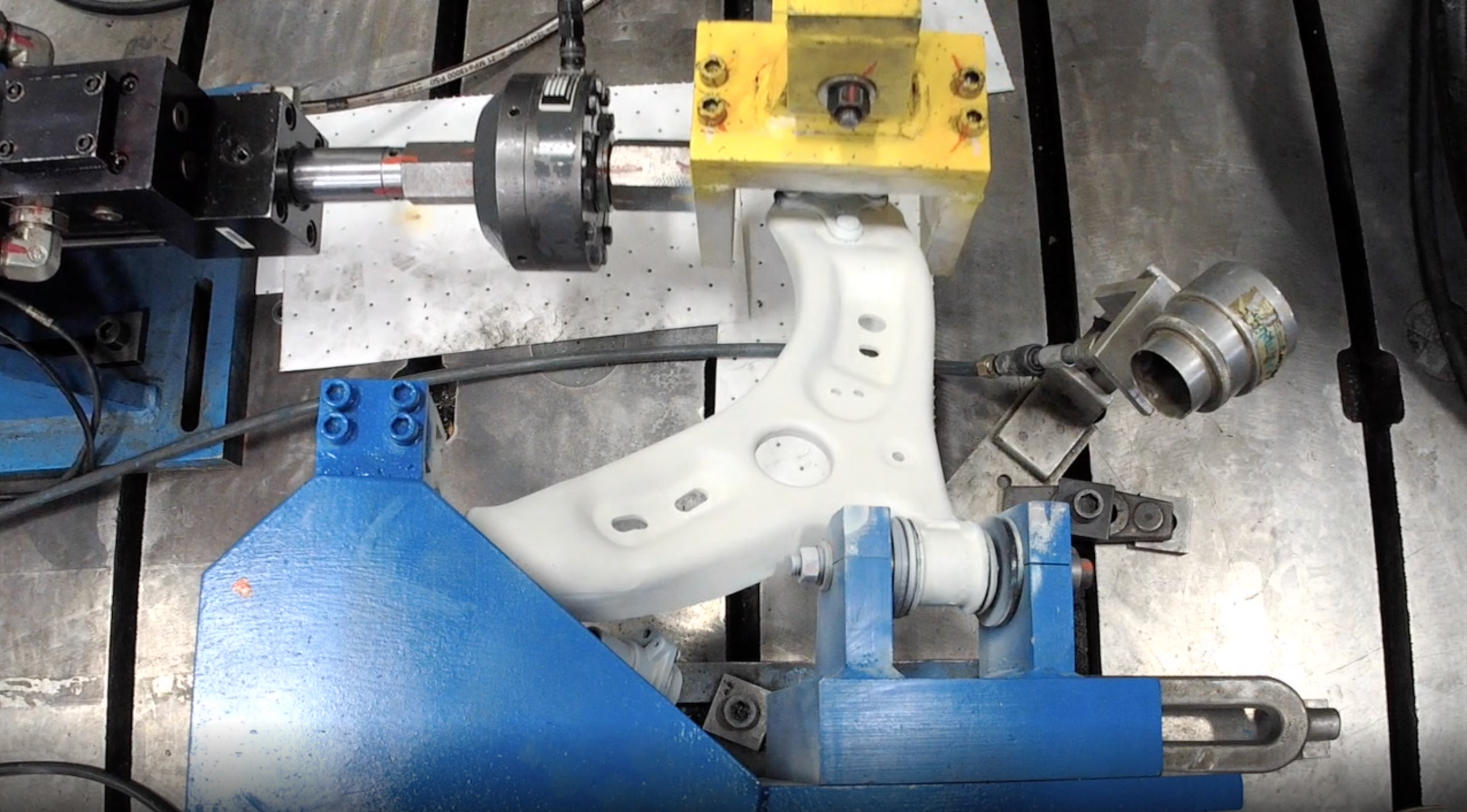

Tested at every turn

We test our parts to the extreme, from every angle. All our control arms undergo rigorous dimensional, material, durability and performance tests, designed to replicate the very same stresses the part will experience on the road. For example, every part is tested on our three axis test rig so all three forces can be analyzed simultaneously; braking force, cornering force and suspension travel movement. And up to 250,000 cycles. Watch this video to see the stresses our control arms withstand in three-axis testing.

We also test their resilience to extreme environmental conditions and corrosive materials. Our purpose-built environmental chamber tests to temperatures as low -40°F and up to 248°F. And our control arms are exposed to 720 hours of salt spray, to evaluate the effect of salt on bushings adhesion. So, you can choose a Delphi control arm with confidence, knowing they’ll perform, even under the harshest conditions.

Cataphoretic coating

Traditional phosphate coatings, applied by dipping or spraying have proven to be ineffective. That’s why our water-based cataphoretic coating uses electrical currents to apply the paint. The environmentally friendly procedure offers increased corrosion protection from salt, dirt and water. And is longer lasting too, providing up to 10 years’ protection.

Why does my control arm look different on this car?

Below is an example of the Double Wishbone Suspension System.

Rear left lower forward? Front right upper rearward?

Naming conventions of control arm positions can be complicated, especially when some modern vehicles can have more than a dozen different control arms, like those with a multilink system, above. Make sure you get the right part the first time. The Delphi Auto Parts App has a simple tool to figure out the location on the vehicle of the part you are replacing and what its position name is. Then, just visit our catalog to find out the Delphi part number for your application.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Chassis product range

Contact Us

Visit our Contact hub to find a range of enquiry types suited to help you find the exact support you are looking for.