HK1400 Expert

Affordable yet full of features, the HK1400 is highly accurate, robust, flexible and user friendly. The essential choice for any diesel workshop wanting to increase their EUI and EUP diagnostic capability. An application kit is also available to allow testing of Cummins HPi®.

- Product Information

- Product Resources

- Enquire

- Related Products

HK1400 Universal Test Bench

The HK1400 is designed to bridge the gap between OEM approved EUI/EUP repair workshops and the general diesel EUI/EUP repair market.

The HK1400 has been engineered so that there is no compromise on accuracy and repeatability of test results, yet the solution has to be affordable for all progressive diesel workshops worldwide. By utilizing and adapting our existing magmah software and keeping development costs to a minimum, it has enabled us to focus on the engineering of the hardware to ensure you get the best there is.

Contact your local Central Distributor for purchase details.

Hartridge Test Plan Database

Test plan database includes coverage for Denso®, Delphi®, Cummins®, and more….

All the testplans, where applicable, include response time limits and they have all been extensively validated to ensure accuracy and to enable workshops to test EUI/EUP to the highest possible standards.

Key EUI/EUP Test Functionality

- Response time measurement

- Electrical resistance

- Fully configurable pulse widths

- Injected quantity shot count

- Automatic test limits generator

- Printable test results and analysis

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

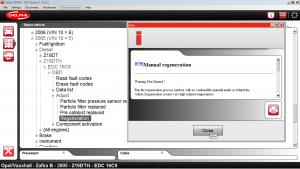

In this article you will find a step by step how to guide for DPF filter regeneration.

Make | Models | System |

Opel | Astra H, Corsa D (Z13DTH and Z13DTJ), Signum, Vectra C, Zafira B | Diesel Systems |

Condensers:

This function is used to burn off the soot particles in the particle filter. It is particularly useful for cleaning the DPF when the vehicle is always driven in an urban environment.

Step By Step

1. | ResolutionFor 2005-2006 models, use the following procedure for the Z19DT and Z19DTH engines:

Regeneration burns the soot particles trapped in the particle filter and the process takes about ten minutes. Place the gear selection lever in the P position (or in neutral for manual transmission). Make sure the parking brake is engaged. Start the engine. Wait until the coolant temperature reaches normal running temperature (80°) before attempting to start the regeneration procedure or the process will not start. Do not touch any of the controls during the process. The engine speed will rise (3500 RPM) and the injection will be retarded to greatly increase the exhaust temperature. White smoke may be produced by the regeneration process. Do not click on the OK button for "Operation finished" (see illustration 1). Wait until the process stops automatically (engine speed will drop to idle automatically) and leave the engine idling for at least 10 minutes before switching off. |

2. | ResolutionIllustration 1If the cycle is interrupted (by accidentally pressing a pedal for example), it is possible to restart the process at the next key on.  |

3. | ResolutionBlower MotorSoot particle burning (regeneration) must be carried out in the open air. The filter particle will reach extremely high temperatures. The vehicle must be parked on a non-flammable surface. To avoid consequent damage, only run the regeneration procedure once! The combustion process can take up to 40 minutes. Test conditions

Procedure1. Click on "OK" to start the operation. 2. A dialogue box will display the coolant temperature. Wait until the temperature reaches the correct value. See test conditions. 3. Click on "OK" to start the regeneration. 4. A dialogue box will display the regeneration status. If the combustion must be cancelled, select "Cancel" and switch the ignition off once the engine speed has stabilized. 5. Regeneration takes around 40 minutes. 6. A dialogue box will display: "Combustion finished" when the process has reached a successful conclusion. In case of failure or cancellation, check the test conditions and replace the particle filter as necessary. |

4. | ResolutionCompressors

|

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Hartridge product range

Find out where to buy Delphi parts