Brake Discs

- Product Information

- Product Resources

- Enquire

- Related Products

ECE R90 certified brake discs

It should come as no surprise that our brake discs for new vehicles launched post 1 st November 2016 are R90 certified, alongside a range for popular older applications. After all, we’ve been meeting these quality standards for many years. The only difference today: our discs now undergo official ECE R90 testing schedules including performance, dynamic friction comparison, high load integrity and thermal fatigue analysis to certify that they perform to a prescribed tolerance of the OE part.

Learn more about Delphi’s R90 certified brake discs and why it matters.

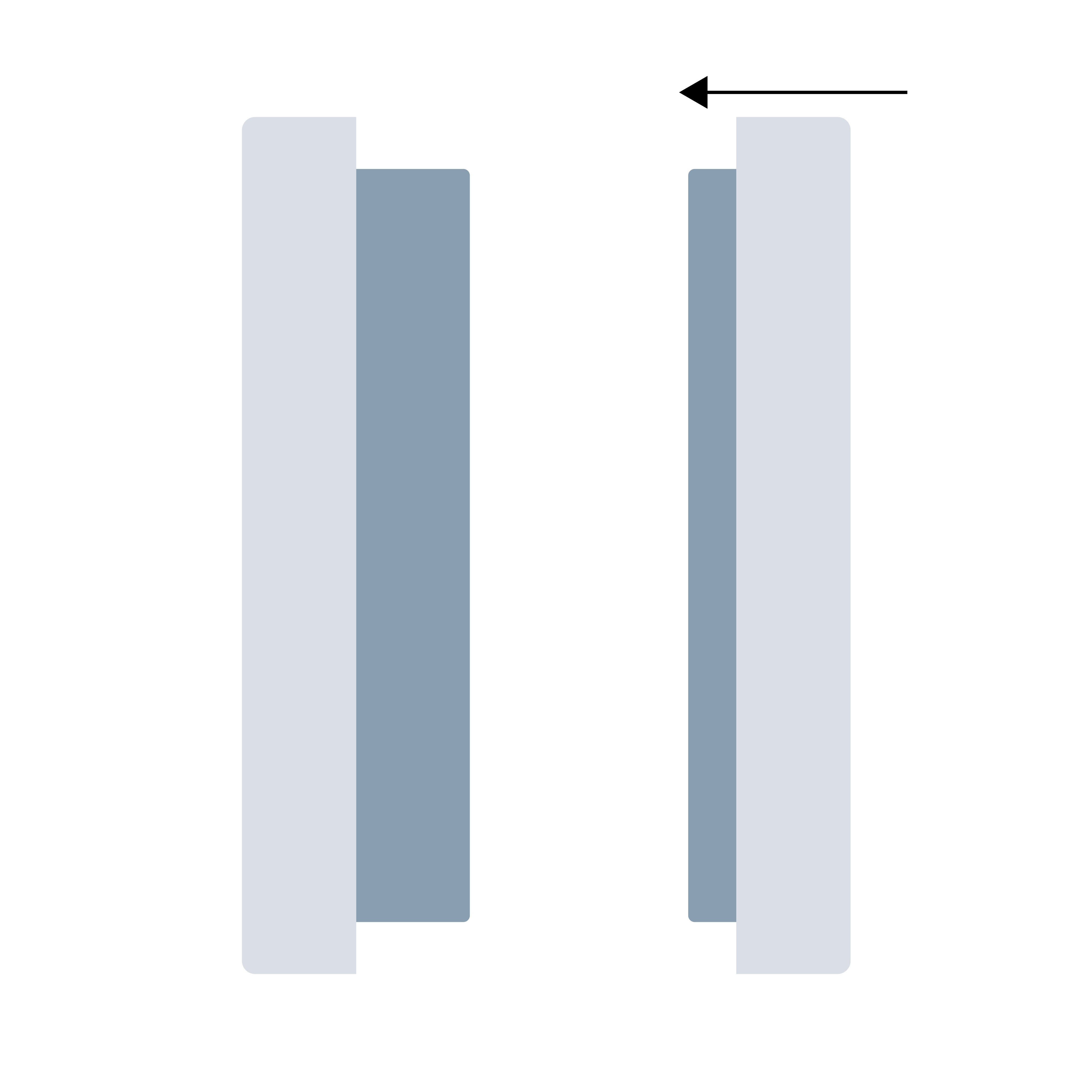

Fully coated brake discs

Thanks to a special zinc-flake, silver Geomet coating, our coated brake discs offer greater and longer-lasting corrosion protection compared with many oil-dipped or partially painted and coated equivalents, whilst also being more cosmetically appealing. And because they have no oil to clean off, they save valuable labour and service time. All this makes for a better protected disc that’s easier to install, easier to dismount as well as being easy on the eye too.

High-carbon brake discs

The added carbon content in our high-carbon discs helps to both reduce the risk of thermal cracking under high-temperature loads, and allows the discs to operate at a cooler temperature, for a more consistent braking performance. It also increases their resistance to distortion or warping for added durability, while delivering noise and judder free braking.

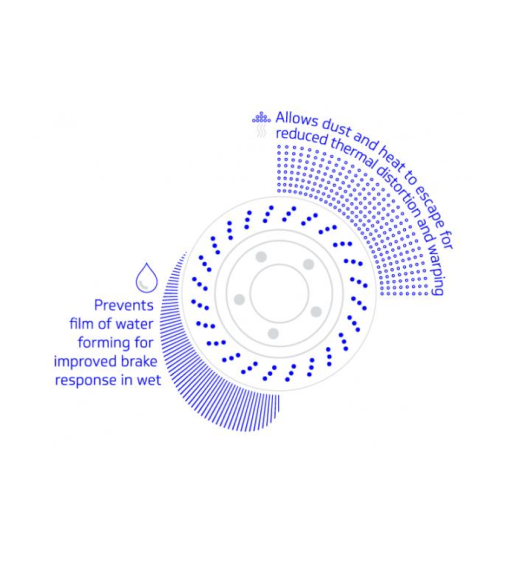

Cross-drilled brake discs

As well as looking cool from behind your wheels, our cross-drilled discs will keep your brakes feeling the same way – cool. The cross-drilled holes dissipate heat, brake dust and gases, helping to keep the pad surface cool and clean and reducing the risk of thermal distortion and warping. These same holes also prevent a film of water forming during wet conditions for improved braked response.

Vented brake discs

Our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock.

Brake discs with bearings

To avoid damage to the bearing during removal, and ensure the correct pressing in into the new, we offer a range of discs with these safety critical components already pre-mounted. They also include both toothed and magnetic ABS sensor rings, as per the OE, and the relevant fixing accessories. All for quick and accurate installation.

One-piece cast iron brake discs

Our one-piece cast iron discs offer an aftermarket alternative to BMW’s patented two-piece bi-metallic composite disc. Engineered from a single piece of cast iron, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but at a fraction of the price. And to top it off, they come with fixing screws for quicker and easier fitting.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, leading braking manufacturer, Delphi, provides a useful guide to the types of wear, causes, basic remedial actions and more in-depth installation advice.

The ability to distinguish between different types of brake pad wear is an important skill for any technician. It will help pinpoint possible causes and streamline diagnosis, saving you and your customer time and money, and ensuring a more accurate repair. Here, leading braking manufacturer, Delphi, provides a useful guide to the types of wear, causes, basic remedial actions and more in-depth installation advice.

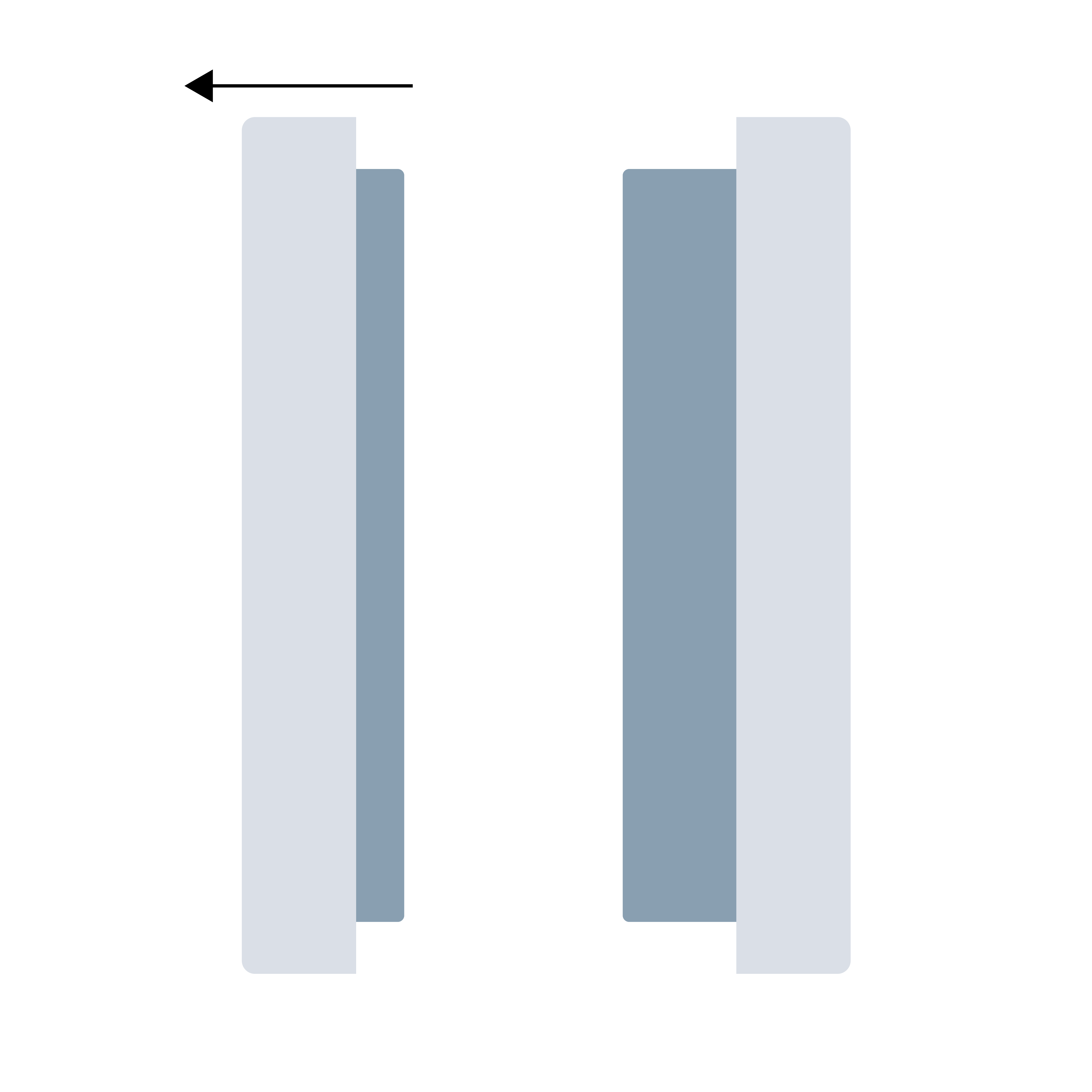

Even Wear: Although your customers might not agree, even wear across both the inside and outside pads on each wheel is positive – it shows that the brake system has been functioning correctly. In this instance, replace the pads and hardware and service the caliper guide pins and slides.

Outer Pad Wear: If the outside pad is worn more than the inside one, the mounting hardware is causing the caliper to seize. Consequently, the caliper will not be able to fully retract the pad from the disc, creating friction even when the brakes aren’t applied. This type of wear is typically caused by seized sliders, guide pins and dry bolts and can be corrected by servicing the mounting hardware, lubricating the sliders and replacing the pads.

Inner Pad Wear: If the inside pad is worn more than the outside one, it is likely that the caliper piston is hanging up and not returning to its rest position. This could be caused by damage or corrosion to the caliper or an issue with the master cylinder. To correct, service or replace the caliper hardware, inspect the caliper for damage to the guide pin hole or piston boot, replacing if needed, check the hydraulic brake system for any residual pressure and replace the pads.

Tapered Pad Wear: If the friction material is worn in a wedge pattern, horizontally or vertically, it’s a good indication that the pad has not been installed correctly. Worn guide pins and a seized caliper slider on one side of the pad can also cause this. To resolve it, service or replace the caliper hardware, lubricate the sliders and replace the brake pads. This can also happen on dual piston, 4 piston and 6 piston calipers where the internal drillings for pressure equalisation are blocked.

Glazed Wear or Cracked Pads: A glazed or cracked pad with lifted edges will shows signs of physical damage and/or thermal distress to the friction material and can signify several problems, usually brought about by excessive heat in the brake system. The most common causes are overuse, improper break-in of new pads, seized calipers, a faulty pad or a parking brake that is not fully retracted. To remedy, simply replace and bed-in the pad and adjust the parking brake if needed.

Overlapping Pad Wear: This happens when the top edge of the pad overlaps the top of the disc. Commons causes include installing the wrong pads or discs on the vehicle or excessive wear to the guide pins, caliper or caliper bracket. To prevent overlapping wear, fit the correct type of pads and discs.

Of course, one of the best ways to prevent excessive wear is by using a pad that is manufactured to the same standards of performance and longevity as the OE. Delphi pads use over 130 different friction ingredients and 20 unique formulations for the best match of pad to vehicle and feature OE noise-absorbing underlayer technology, chamfers and shims.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi product range

Find out where to buy Delphi parts