Brake Discs

- Product Information

- Product Resources

- Enquire

- Related Products

ECE R90 certified brake discs

It should come as no surprise that our brake discs for new vehicles launched post 1 st November 2016 are R90 certified, alongside a range for popular older applications. After all, we’ve been meeting these quality standards for many years. The only difference today: our discs now undergo official ECE R90 testing schedules including performance, dynamic friction comparison, high load integrity and thermal fatigue analysis to certify that they perform to a prescribed tolerance of the OE part.

Learn more about Delphi’s R90 certified brake discs and why it matters.

Fully coated brake discs

Thanks to a special zinc-flake, silver Geomet coating, our coated brake discs offer greater and longer-lasting corrosion protection compared with many oil-dipped or partially painted and coated equivalents, whilst also being more cosmetically appealing. And because they have no oil to clean off, they save valuable labour and service time. All this makes for a better protected disc that’s easier to install, easier to dismount as well as being easy on the eye too.

High-carbon brake discs

The added carbon content in our high-carbon discs helps to both reduce the risk of thermal cracking under high-temperature loads, and allows the discs to operate at a cooler temperature, for a more consistent braking performance. It also increases their resistance to distortion or warping for added durability, while delivering noise and judder free braking.

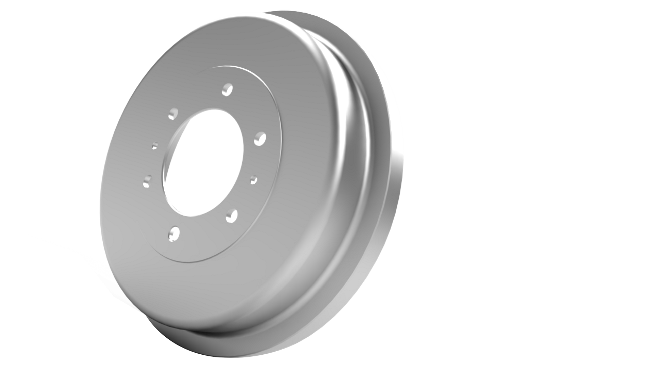

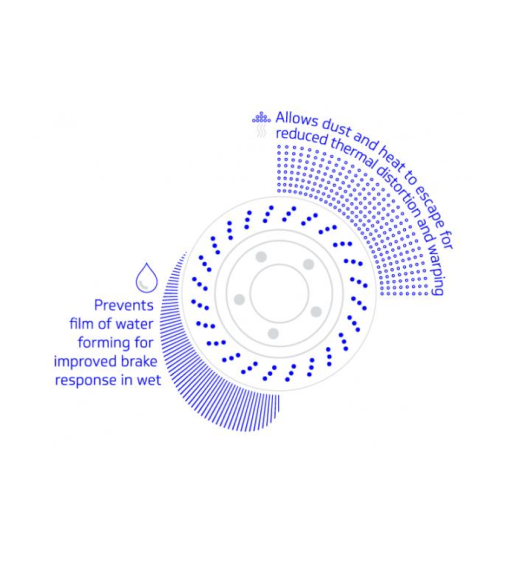

Cross-drilled brake discs

As well as looking cool from behind your wheels, our cross-drilled discs will keep your brakes feeling the same way – cool. The cross-drilled holes dissipate heat, brake dust and gases, helping to keep the pad surface cool and clean and reducing the risk of thermal distortion and warping. These same holes also prevent a film of water forming during wet conditions for improved braked response.

Vented brake discs

Our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock.

Brake discs with bearings

To avoid damage to the bearing during removal, and ensure the correct pressing in into the new, we offer a range of discs with these safety critical components already pre-mounted. They also include both toothed and magnetic ABS sensor rings, as per the OE, and the relevant fixing accessories. All for quick and accurate installation.

One-piece cast iron brake discs

Our one-piece cast iron discs offer an aftermarket alternative to BMW’s patented two-piece bi-metallic composite disc. Engineered from a single piece of cast iron, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but at a fraction of the price. And to top it off, they come with fixing screws for quicker and easier fitting.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article you will find out about Brake Pads. When it comes to stopping, every meter counts. Unlike some of our competition we do not trade off shorter stopping distances for noise, quietness, or increased wear. Our brake pads perform exceptionally well in dry or wet conditions.

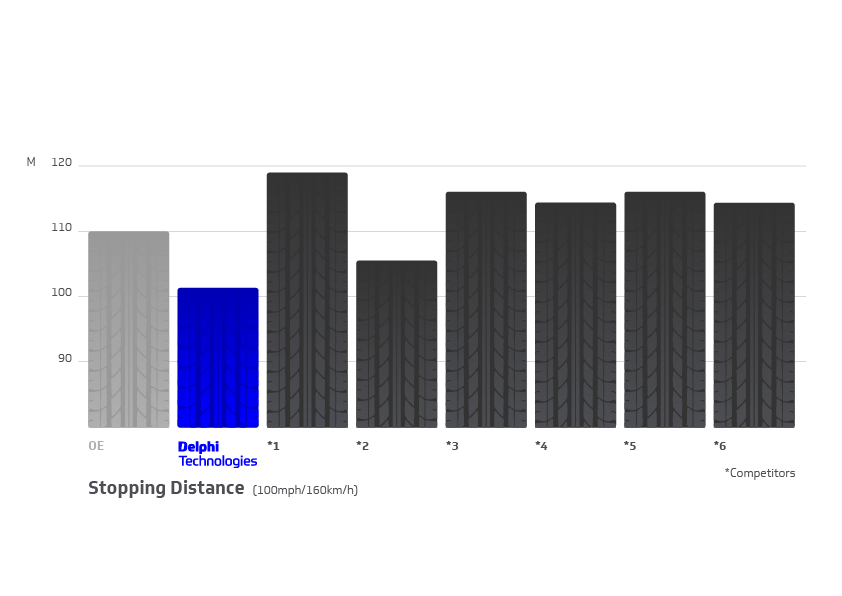

That's right! Unlike some of our competitors we don't trade off shorter stopping distances for noise. Or quietness for increased wear. Or any other performance measure, come to that. Far from it! In recent tests our pads fitted to a VW Passat 2.0 TSI excelled in all key areas: they stopped quicker, quieter and lasted longer than the OE and six other leading aftermarket brands.

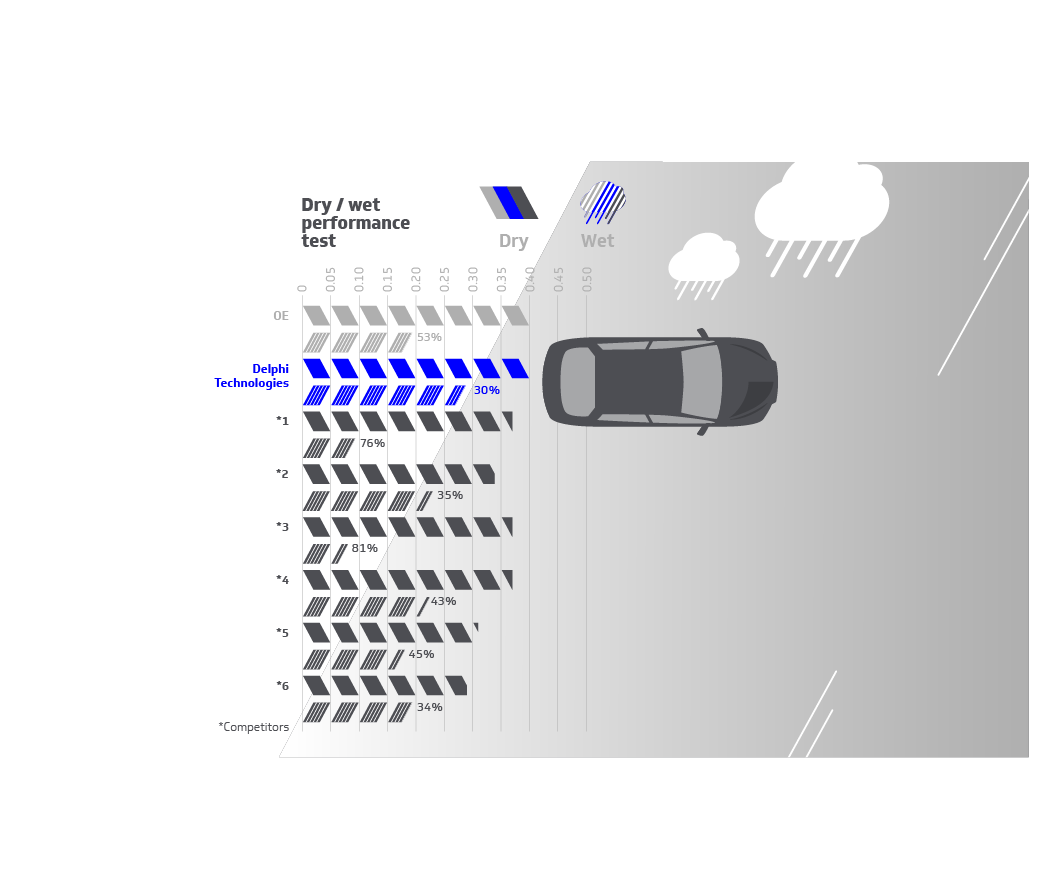

When it comes to stopping, every meter counts. Literally! It could mean the difference between a near collision and a nasty bump. And we know which one we'd choose in those circumstances. The good news - at ECE Regulation 90 speeds of 100 mph, our pads stopped the quickest and by some way. Four meters ahead of the next placed brand and over 17 meters ahead of the worst. Better still, and unlike some of our competitors, the vehicle fitted with Delphi pads stopped under control. In technical terms that means a stable friction coefficient that performs like the OE.

Our pads stopped equally well in the wet too. Whilst in an ideal world the vehicle would stop in the wet, exactly as it did in the dry – we know brakes are less effective in wet weather. Delphi provided the lowest reduction in friction levels from dry to wet conditions, with an average loss of 30 percent across the six stops, compared with 34 percent for the next best brand and 81 percent for the worst. So come rain or shine, our pads outperform the competition.

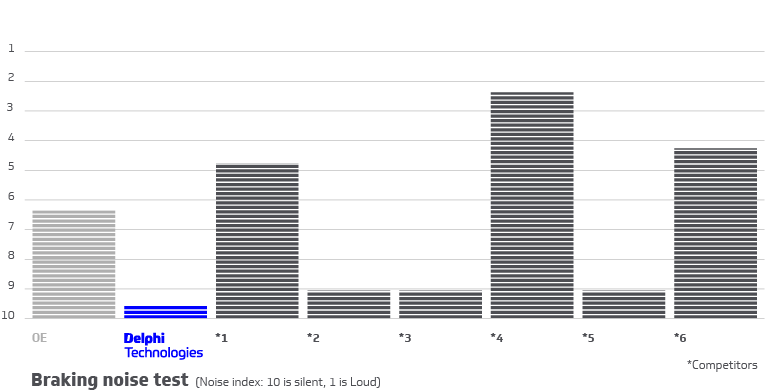

We know that noise is one of the biggest issues for both car drivers and technicians. Not with Delphi pads. That's because on the noise index they recorded a near silent 9.6. And on the odd occasion that they registered noise above the 70db threshold...well it's hardly worth mentioning because it occurred 0.1 percent of times – that’s only one out of every 1000, and well below most vehicle manufacturers noise limits of ten percent.

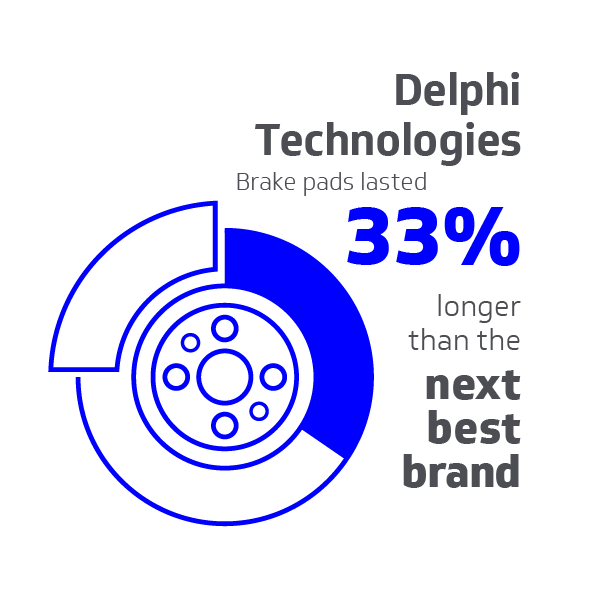

By now you won't be surprised to hear that our pads lasted the longest too. After 2140 stops, our front axle pad, where most of the braking is done, experienced the least wear with only 0.9 mm – lasting 33 percent longer than the next closest brand and providing exceptional value for money. Some say perfection doesn't exist. With these results, we like to think our brake pads are very nearly there.

Read on for more on stopping distances, noise, wear and wet braking.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi product range

Find out where to buy Delphi parts