Brake Discs

ECE R90 certified brake discs

It should come as no surprise that our brake discs for new vehicles launched post 1 st November 2016 are R90 certified, alongside a range for popular older applications. After all, we’ve been meeting these quality standards for many years. The only difference today: our discs now undergo official ECE R90 testing schedules including performance, dynamic friction comparison, high load integrity and thermal fatigue analysis to certify that they perform to a prescribed tolerance of the OE part.

Learn more about Delphi’s R90 certified brake discs and why it matters.

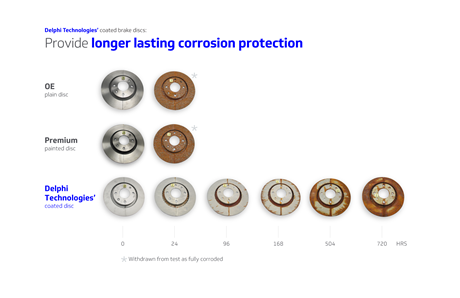

Fully coated brake discs

Thanks to a special zinc-flake, silver Geomet coating, our coated brake discs offer greater and longer-lasting corrosion protection compared with many oil-dipped or partially painted and coated equivalents, whilst also being more cosmetically appealing. And because they have no oil to clean off, they save valuable labour and service time. All this makes for a better protected disc that’s easier to install, easier to dismount as well as being easy on the eye too.

High-carbon brake discs

The added carbon content in our high-carbon discs helps to both reduce the risk of thermal cracking under high-temperature loads, and allows the discs to operate at a cooler temperature, for a more consistent braking performance. It also increases their resistance to distortion or warping for added durability, while delivering noise and judder free braking.

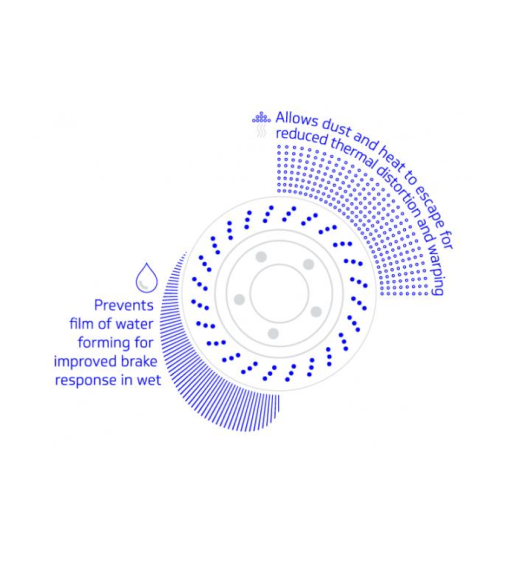

Cross-drilled brake discs

As well as looking cool from behind your wheels, our cross-drilled discs will keep your brakes feeling the same way – cool. The cross-drilled holes dissipate heat, brake dust and gases, helping to keep the pad surface cool and clean and reducing the risk of thermal distortion and warping. These same holes also prevent a film of water forming during wet conditions for improved braked response.

Vented brake discs

Our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock.

Brake discs with bearings

To avoid damage to the bearing during removal, and ensure the correct pressing in into the new, we offer a range of discs with these safety critical components already pre-mounted. They also include both toothed and magnetic ABS sensor rings, as per the OE, and the relevant fixing accessories. All for quick and accurate installation.

One-piece cast iron brake discs

Our one-piece cast iron discs offer an aftermarket alternative to BMW’s patented two-piece bi-metallic composite disc. Engineered from a single piece of cast iron, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but at a fraction of the price. And to top it off, they come with fixing screws for quicker and easier fitting.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we take a closer look at brake noise, what causes it and how, in a number of steps, you can resolve it.

You know that annoying sound you get when you pull up at the lights? Could be a high pitch squeal, screech, groan or rattle? Well that’s brake noise and it can be one of the first signs that something is wrong with your brakes. It’s also one of the biggest sources of customer comebacks for any garage. Yet, unfortunately is often one of the most difficult issues to solve. Here we take a closer look at brake noise, what causes it and how, in a number of steps, you can resolve it.

What is Brake Noise?

Let’s get back to basics. In simple terms, sound is vibration. Whether it’s a bird tweeting, an acoustic guitar or a clap of thunder, its vibrations sets the air around it in motion, creating a sound wave. Its pitch is determined by the speed of vibration.

The same is true when it comes to brake noise. All braking components vibrate to some extent, creating noise. For the most part this noise is not detectable by the human ear. However when this vibration increases in intensity, or induces a secondary vibration in another part, the brake disc acts like a speaker, amplifying the noise and making the vibration audible. The result? Brake noise.

What causes brake noise?

Brake noise can be caused by a variety of component and installation issues. Excessive corrosion, seized or bent location pins, partially seized calipers, built up dirt and brake dust, excessive runout, disc thickness variation (DTV) or worn brake discs can all cause vibration between the disc and the brake pad creating brake noise. Whilst the brake system is the most common cause, noise can also be created when the motion in braking creates movement in another part, typically steering components and motor and transmission mounts.

Types of brake noise.

Yes it’s true! There are different types of brake noise, all determined by the frequency of the vibration. For example, a slow vibration can sound like a groan, whereas a faster vibration is more like a squeal. The common types of brake noise can be summarised as:

- Judder: low frequency vibrations - below 300hz. Causes include poor fitment of the disc brake onto the hub, damage to the disc, excessive disc thickness variation and runout.

- Squeal: medium frequency vibrations - 300 to 5kHz. Causes include a sticky caliper piston or slider pins, incorrect pad installation, heavily worn discs and friction material scoring.

- Squeak: high frequency vibrations - over 5kHz. Normally caused by a vibration with the friction material during application to the disc.

- Ultrasound: very high frequency vibrations - over 12kHZ (exceeds human hearing).

Aside from the above, other noises may include grinding, usually caused by a lack of friction material so the pads and discs are metal to metal, and scraping which may mean a foreign body is lodged between the pad and disc.

What to look out for.

It’s a good idea to carefully check the entire system, especially the pads, as they’re normally a good indication that something’s not right. For example tapered wear on the pads could suggest a faulty caliper. A damaged back plate implies excessive force used during installation. Similarly thickness variation on the disc is a sure sign of judder. Other signals to look out for include uneven pad wear, brake fluid leaks, piston damage and sticky caliper sliders.

Best practice fitting advice.

To minimise brake noise related issues, it’s important to follow some best practice advice.

- Ensure that all corrosion, built up dirt and brake dust is removed from the caliper.

- Always clean exposed caliper piston surfaces before retracting the pistons. Ease piston retraction by opening the bleed nipple. Retract piston(s) with a suitable tool. Never lever against the disc friction face.

- Thoroughly clean pad contact points in the caliper.

- Check pistons, seals, boots and sliding elements on the caliper to ensure that they are free from damage and corrosion and able to slide.

- Replace all anti-rattle clips, springs and pins, which can lose their spring tempering due to the high brake heat.

- Always check the disc for minimum thickness, DTV and runout when fitting new pads.

- Always check that the correct pads are fitted and that they’re positioned correctly in the caliper. They should fit freely in the brackets to avoid ongoing contact with the discs.

- Never use clamps on brake hoses. Hoses contain multiple layers of braiding which give them their structural strength. The hose may become damaged or crushed, leading to hydraulic issues such as blockage or fluid leaks.

- Never use mineral oil based lubricants on parts with rubber seals. This will cause the seals to swell.

- In some instances, you’ll need to replace the discs and/or pads. For step-by-step instructions on how to do this, watch Delphi’s installation video on our YouTube channel.

Noise Fixes from Delphi

Of course, one of the best ways to prevent brake noise is by only using OE quality brake pads – poor quality pads are one of the biggest contributors to noise. In recent years, demands for higher performance and reduced weight in modern vehicles have led to material changes, resulting in increased use of supplementary processes to counteract vibrations.

Unlike other aftermarket manufacturers, every Delphi brake pad incorporates OE underlayer technology. The 3mm layer of modified noise-absorbing friction material provides 83 percent less noise occurrences above 70db, as well as acting as a thermal insulator and ensuring a stronger pad.

Delphi pads also feature OE-configured, OE quality chamfers and shims. Fitted as per the OE, Delphi shims are multi-layered with differing grades of dampening materials. These layers are finely tuned by engineers to bring out the very best qualities. The material is carefully selected and either mechanically attached, clipped and/or hot bonded for improved noise dampening.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi product range

Find out where to buy Delphi parts