Gasoline Direct Injection (GDi) Systems

- Product Information

- Product Resources

- Enquire

- Related Products

Raising the bar with OE technology

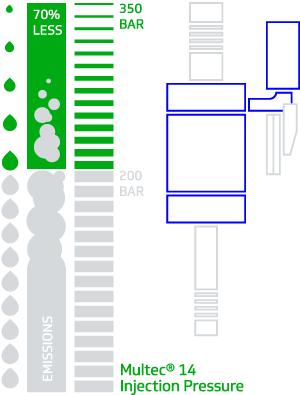

Our industry-first Multec® 14 (M14) 350-bar pressure injection system raises the bar, taking injection pressure from 200 to 350 bar. By injecting smaller droplets into the combustion chamber faster, the latest generation system delivers fewer hydrocarbons and particulate emissions – up to 70 percent - and increased fuel savings. And if that’s not enough, we’re already working on a 500 bar solution.

OE expertise in the aftermarket

We bring our OE expertise to the aftermarket too. Our GDi service programme features our award winning Multec® GDi multi-hole fuel injectors for optimised fuel delivery and combustion, low noise GDi high pressure fuel pumps and service kits, giving you access to OE parts for a high-quality, competitive service. Understand more about the common service issues with GDi.

More than parts

We also offer a comprehensive electronic and hydraulic diagnostic solution including our proven on-board DS diagnostic tool, a high-pressure diagnostic kit, HD3000, allowing technicians to safely set and electronically control any pressure test point up to 3000 bar and a wide-ranging low-pressure tester, LP35.

Training from the OE experts

Want to learn more about GDi servicing? Our range of one day specialist training courses combines theory with practical, on-vehicle exercises and cover key topics such as component operation, common systems and faults, using high pressure gasoline and more. Giving you the skills and know-how to service the latest GDi equipped vehicles.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

The removal and replacement of GDI injectors from a diesel engine is a fairly straightforward task. But the injectors’ role in compressing and injecting fuel makes it exceptionally important to get the replacement right, for safety reasons as well as ensuring the correct performance.

Watch the video guide from one of our expert Delphi technicians as they walk you through the steps involved in refitting GDI safely, including some advice on:

Why GDI systems can pose a safety risk

How to stop tip seals tearing when refitting

How to check for leaks.

How often do I change GDI injectors?

GDI systems are typically inspected when a fault is detected, when the driver notices a loss in engine performance, or when the driver is experiencing poor fuel economy.

Is direct fuel injection the same as GDI?

GDI stands for gasoline direct injection, which is a kind of direct fuel injection. Unlike multipoint injection systems, GDI uses high pressure fuel injection to fire directly into the combustion chamber.

What is the pressure for GDI injectors?

A GDI system operates between 50 and 500 bar. That’s approximately 725 to 7250 psi. At these high pressures, technicians must take extra care when handling components and refitting a GDI system.

What are some common issues with GDI injectors?

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Fuel Injection System product range

Find out where to buy Delphi parts