Resource Highlights

In this article, you will find out about the Automotive Diagnostic Tools. Here we examine why and how, with the support of Delphi, you can gear-up and take advantage of this rapidly growing, profitable opportunity.

You don’t need a crystal ball to see that automotive diagnostic tools will become increasingly pivotal to a garage’s long term future. Thanks to the digitization of a vehicle’s components, it has evolved from the reserve of the specialist workshop, to a key component for any garage wanting to offer a comprehensive range of services to their customers. Here we examine why and how, with the support of Delphi, you can gear-up and take advantage of this rapidly growing, profitable opportunity.

You only need to look back to the early 2000s to see just how far automotive technology has come in recent years. The majority of systems on the vehicle were still largely mechanical. The professionals who serviced them were called mechanics for good reason after all. Their go-to toolkit hosted wrenches, ratchets, & screw drivers. Working knowledge and visual checks were enough for most tasks.

Fast forward to today and that just won’t cut it anymore. Today’s vehicle can have up to 50 computers embedded beneath their skin, all communicating with tens of millions of lines of code.

A variety of systems from fuel & braking, to air conditioning & parking sensors are monitored & controlled through electronic systems. Even a basic service requires digital resetting to inform the ECU to detect new filters & for correct service life monitoring. As new technologies such as hybridization & active safety systems become more established, the number of components that rely on electrification will only continue to increase.

Take Advanced Driver Assistance Systems (ADAS) as an example. Parking sensors, pedestrian detection, and cameras are now fitted as standard in most modern vehicles and are used daily by the driver for comfort and safety.

A technician will need to perform static or dynamic calibrations as a result of a range of service and repair tasks to ensure these critical systems function as they should. And you guessed it; they’ll need a diagnostic tool to do that. Having the right vehicle diagnostic tool has therefore become a must for any workshop. As well as enabling technicians to quickly, safely, & accurately pinpoint a repair, for many it’s the key to ensuring they can retain the work in-house and increase the profitability of each repair.

Advanced diagnostic solutions... at the touch of a button

Who better to provide this than Delphi, global pioneer in propulsion technologies, services, and solutions at the leading edge of engineering advances.

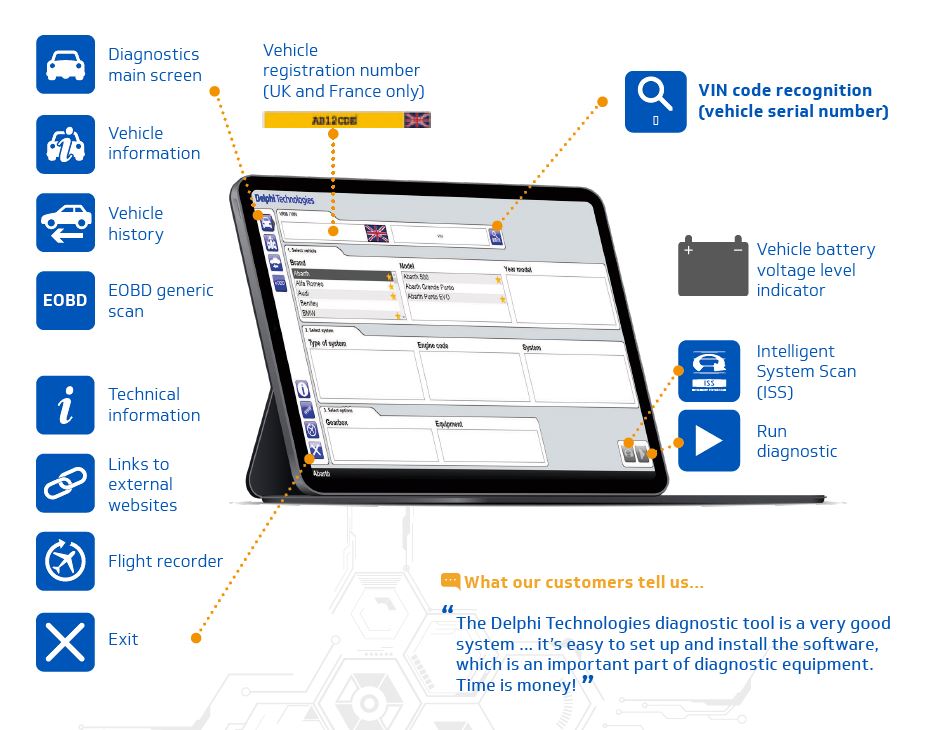

That’s why we’ve developed a range of innovative, holistic diagnostic solutions which are built around the needs of our customers. Our advanced DS diagnostic solution gives you the capability to read fault codes, view live data, perform specific functions across a wide range of vehicle makes and models.

This comprehensive multi sector coverage makes it an invaluable tool for specialist and multi-brand garages alike. With growing demand on minimizing vehicle downtime, it also offers a number of time and money saving features for quick, easy & accurate diagnostics and repair, such as VRM look-up, help files, and reporting function.

And if this isn’t enough, simply hook up to the vehicle technical information integrated into the device, or as a standalone package, to gain in-depth maintenance and repair data that will guide a technician through the process step by step.

So, with in-built OE expertise at your fingertips, you won’t have to turn to the mysteries of a fortune teller to diagnose your future. Far from it! Together with the expert training and technical support that come with all our diagnostic tools, you’ll have everything you need to meet the needs of the increasingly complex market and set yourself up for future success.

Want to know more? Click here to have a look at our diagnostics frequently asked questions

Learn more about our diagnostic training and how it could help develop your workshop capabilities!

Unlock your full Business Potential. Read our Diagnostic Brochure to learn more about our solution!

Delphi takes pride in delivering high quality, reliable and accurate diagnostic solutions. But, sometimes the best solutions are copied with inferior, low quality, counterfeit products. Always buy official Delphi solutions with confidence.

SIGN UP TO FIND MORE

Fill up your details to hear more from our experts and get the latest updates from Delphi.