Featured News

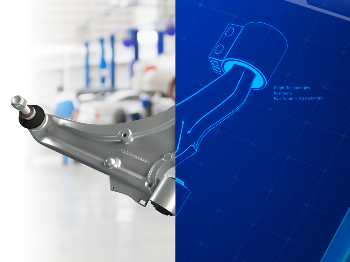

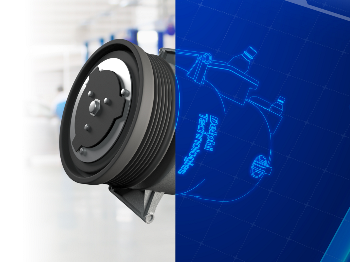

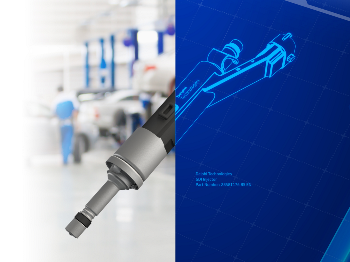

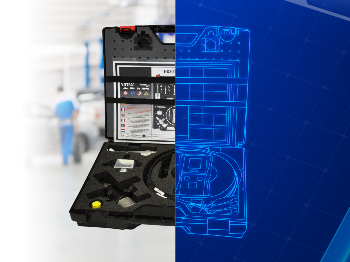

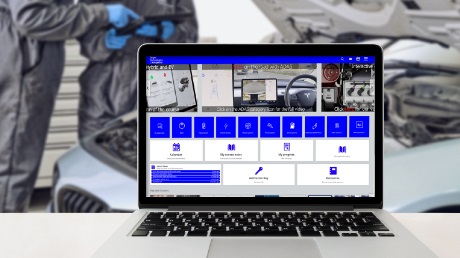

Precision And Performance With Delphi's Expanding S&S Range

Vehicle stability, control, and safety hinge on superior steering and suspension (S&S) systems. That’s why we are relentless in our pursuit to deliver top-quality products and continuous innovation.

Precision And Performance With Delphi's Expanding S&S Range: Read more"Precision And Performance With Delphi's Expanding S&S Range"