Brake Discs

- Product Information

- Product Resources

- Enquire

- Related Products

ECE R90 certified brake discs

It should come as no surprise that our brake discs for new vehicles launched post 1 st November 2016 are R90 certified, alongside a range for popular older applications. After all, we’ve been meeting these quality standards for many years. The only difference today: our discs now undergo official ECE R90 testing schedules including performance, dynamic friction comparison, high load integrity and thermal fatigue analysis to certify that they perform to a prescribed tolerance of the OE part.

Learn more about Delphi’s R90 certified brake discs and why it matters.

Fully coated brake discs

Thanks to a special zinc-flake, silver Geomet coating, our coated brake discs offer greater and longer-lasting corrosion protection compared with many oil-dipped or partially painted and coated equivalents, whilst also being more cosmetically appealing. And because they have no oil to clean off, they save valuable labour and service time. All this makes for a better protected disc that’s easier to install, easier to dismount as well as being easy on the eye too.

High-carbon brake discs

The added carbon content in our high-carbon discs helps to both reduce the risk of thermal cracking under high-temperature loads, and allows the discs to operate at a cooler temperature, for a more consistent braking performance. It also increases their resistance to distortion or warping for added durability, while delivering noise and judder free braking.

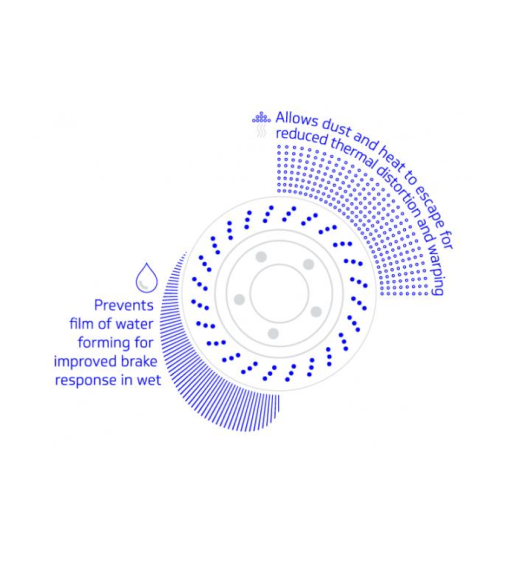

Cross-drilled brake discs

As well as looking cool from behind your wheels, our cross-drilled discs will keep your brakes feeling the same way – cool. The cross-drilled holes dissipate heat, brake dust and gases, helping to keep the pad surface cool and clean and reducing the risk of thermal distortion and warping. These same holes also prevent a film of water forming during wet conditions for improved braked response.

Vented brake discs

Our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock.

Brake discs with bearings

To avoid damage to the bearing during removal, and ensure the correct pressing in into the new, we offer a range of discs with these safety critical components already pre-mounted. They also include both toothed and magnetic ABS sensor rings, as per the OE, and the relevant fixing accessories. All for quick and accurate installation.

One-piece cast iron brake discs

Our one-piece cast iron discs offer an aftermarket alternative to BMW’s patented two-piece bi-metallic composite disc. Engineered from a single piece of cast iron, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but at a fraction of the price. And to top it off, they come with fixing screws for quicker and easier fitting.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

In this article, we talk about some simple best practice procedures, you can ensure a noise and vibration-free brake job, significantly reducing the possibility of any braking comebacks.

The last thing you want when you’ve performed a straightforward brake job is the customer returning a short while later with a complaint. Yet unfortunately brakes are one of the biggest sources of customer comebacks for many garages. They needn’t be! Because whilst some issues are outside the technicians control, others can be avoided from the outset. By following some simple best practice procedures, you can ensure a noise and vibration-free brake job, significantly reducing the possibility of any braking comebacks.

Inspect: Before replacing any parts, conduct a thorough inspection of the braking system including the condition of the pads, discs, calipers, mounting hardware and parking brake cables etc. Pay particular attention to how components such as the brake pads have worn as this can help to identify possible causes. It also pays to inspect the rest of the vehicle, as certain complaints such as brake noise, can be accentuated, mimicked and even caused by other systems. Missing vital and often simple clues at this stage could result in a comeback.

Clean: Before the disc is installed it’s important to ensure that the hub and disc mounting faces are scrupulously clean and free from any rust, dirt or grease that could affect the runout of the assembly. Any contaminants remaining on the disc’s mounting surface could also transfer to the pads, reducing their friction coefficient. Yet unfortunately this process is all too often ignored. Use a cloth and appropriate solvent to clean the disc, and a wire brush for the hub. Also, wear clean latex gloves during installation to avoid further contamination.

In addition to disc cleanliness, examine the caliper and its mounting hardware, ensuring that all corrosion, built up dirt and brake dust is removed, as this can easily affect caliper fit and movement. Again, use a wire brush to remove any rust or dirt from the caliper brackets/guides, clean or replace the hardware, and clean all pad contact points. Failure to do this during brake servicing can result in seized/sticking pads, brake noise and premature wear.

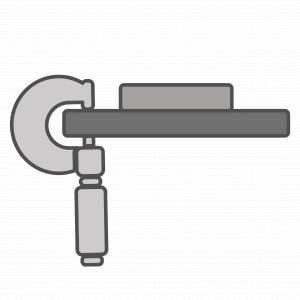

Measure: Before refitting, check the disc for any variations in thickness. Using a brake disc micrometer measure the disc’s thickness, at six to eight equidistant points around its perimeter – never from a single spot - and 10mm from the edge. Compare the results to specification. If it’s outside the manufacturer’s tolerances then it cannot be serviced and must be replaced; as a rule of thumb, the maximum allowable thickness variation is around 0.015mm.

Once fitted, use a dial indicator to check the disc’s lateral runout. The disc must be securely fitted and evenly bolted up on the hub and the dial test indicator securely anchored to a non-moving fixture such as a control arm. Position the plunge tip about 10mm inside the rotor edge at a 90° angle, zero the gauge and slowly rotate the disc through 360°, recording maximum and minimum runout as well as the disc’s location on the hub. Whilst tolerances will vary from make to model, less than 0.05 to 0.10mm is a good target for maximum runout limit. If runout is out of tolerance recheck the disc fitment onto the hub, if this is correct remove the disc and measure run out on the wheel bearing/hub unit too. Disc runout may or may not be caused by disc thickness variation. So, if there’s no evidence of disc thickness variation, then the disc may be rotating of its true axis as a result of other damage or hub face contamination. Either way, excessive run out will eventually lead to disc thickness variation and a vibrating/pulsating brake pedal. The root cause must therefore be identified and fixed.

Lubricate: Apply a high-performance brake grease to all metal-to-metal contact points between the brake pad and caliper. Never coat the friction material, the disc’s surface or rubber parts/shims.

Replace hardware: Always replace pad-to-caliper hardware i.e. anti-rattle clips, adjustment springs and pins when installing new pads. These are exposed to the same heat, moisture and corrosion as the pads and discs and will gradually lose their tension, allowing unwanted vibration and movement between the pads and caliper that can create and amplify noise. Pad hardware is cheap, but failure to replace it with new could cause a noise related comeback, and negatively impact braking performance and durability.

Use shims: Shims provide further insulation against both vibration and heat and should never be ignored. Quality brake pads, such as Delphi, come with OE shims either preinstalled or loose as per the OE. If loose, remember to position the shim correctly on the back of the pad before installing, otherwise it might create more noise than it absorbs. And as a rule, don’t reuse shims. They are exposed to significant force every time the brakes are applied and will lose their elasticity and ability to dampen over time. The only exception to this is stainless steel shims assuming they are both clean and not corroded or bent.

Torque: Brake components and wheels need to properly torqued on reassembly. Unevenly or over torqued wheels can lead to a warped disc hat, especially on thin-hat discs, whereas excessive torque on the discs positioning screws could distort the hub contact surface – both could cause pedal pulsation. Refer to the vehicle handbook for the correct specifications.

Road test: Last but not least, perform a full road test to properly bed-in in the pads and discs, with 10 stops at 60% braking effort, from 60mph to 20mph. During this procedure try to avoid heavy 100% braking or activating the ABS, and never leave your foot on the brake pedal. This will allow the two mating surfaces, the pad and disc, to transfer a layer of material to each other – pad to disc and disc to pad – in order to seat together and deliver optimal braking performance from the outset.

By following a few best practice procedures such as proper cleaning, measuring, lubing and importantly only installing quality parts, with new hardware, brake job comebacks can be easily avoided.

Watch below to see how to replace a brake pad and disc:

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi product range

Find out where to buy Delphi parts