Brake Discs

- Product Information

- Product Resources

- Enquire

- Related Products

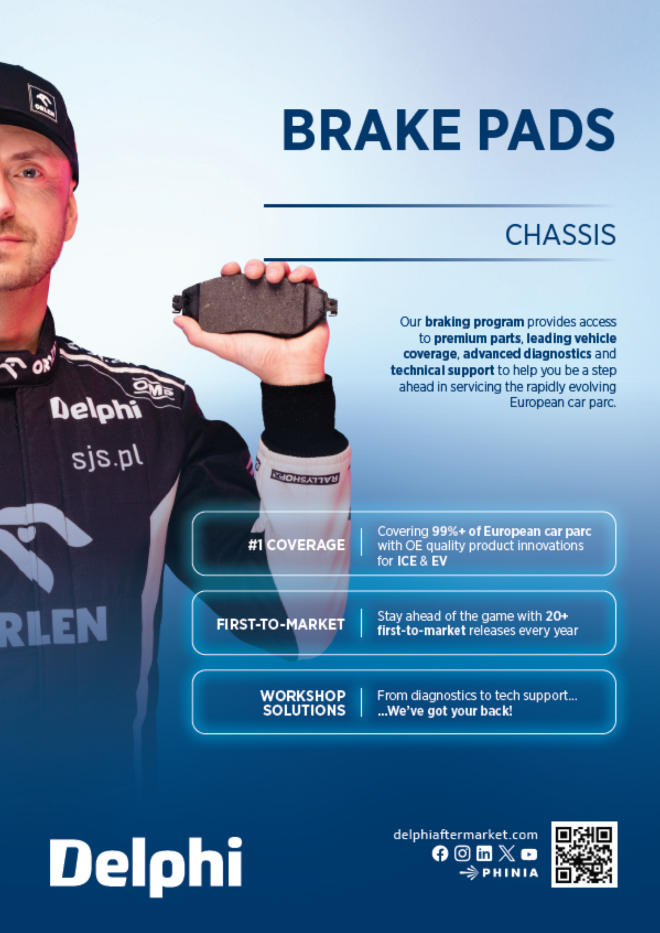

ECE R90 certified brake discs

It should come as no surprise that our brake discs for new vehicles launched post 1 st November 2016 are R90 certified, alongside a range for popular older applications. After all, we’ve been meeting these quality standards for many years. The only difference today: our discs now undergo official ECE R90 testing schedules including performance, dynamic friction comparison, high load integrity and thermal fatigue analysis to certify that they perform to a prescribed tolerance of the OE part.

Learn more about Delphi’s R90 certified brake discs and why it matters.

Fully coated brake discs

Thanks to a special zinc-flake, silver Geomet coating, our coated brake discs offer greater and longer-lasting corrosion protection compared with many oil-dipped or partially painted and coated equivalents, whilst also being more cosmetically appealing. And because they have no oil to clean off, they save valuable labour and service time. All this makes for a better protected disc that’s easier to install, easier to dismount as well as being easy on the eye too.

High-carbon brake discs

The added carbon content in our high-carbon discs helps to both reduce the risk of thermal cracking under high-temperature loads, and allows the discs to operate at a cooler temperature, for a more consistent braking performance. It also increases their resistance to distortion or warping for added durability, while delivering noise and judder free braking.

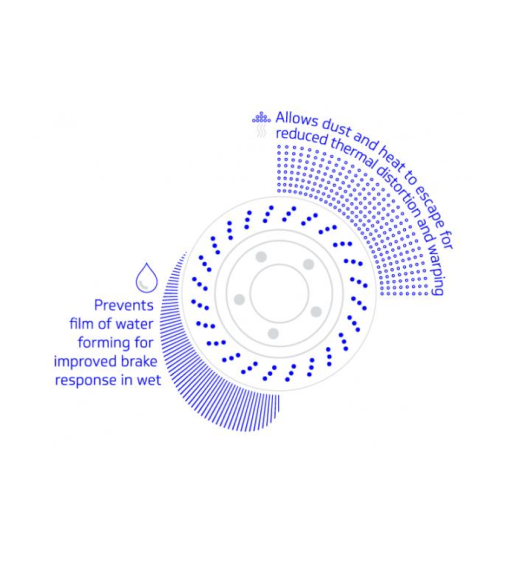

Cross-drilled brake discs

As well as looking cool from behind your wheels, our cross-drilled discs will keep your brakes feeling the same way – cool. The cross-drilled holes dissipate heat, brake dust and gases, helping to keep the pad surface cool and clean and reducing the risk of thermal distortion and warping. These same holes also prevent a film of water forming during wet conditions for improved braked response.

Vented brake discs

Our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock.

Brake discs with bearings

To avoid damage to the bearing during removal, and ensure the correct pressing in into the new, we offer a range of discs with these safety critical components already pre-mounted. They also include both toothed and magnetic ABS sensor rings, as per the OE, and the relevant fixing accessories. All for quick and accurate installation.

One-piece cast iron brake discs

Our one-piece cast iron discs offer an aftermarket alternative to BMW’s patented two-piece bi-metallic composite disc. Engineered from a single piece of cast iron, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but at a fraction of the price. And to top it off, they come with fixing screws for quicker and easier fitting.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Resource Highlights

Like every good performer, we have our own collection of top selling discs. From cross drilled to vented, and high-carbon to coated. We think of it as our own ‘discography’…but for cars instead of your ears.

Since every car is different, and every driver is different, what is right for one, might not work quite as well for the other. And vice versa. That’s why our engineers consider many variables when developing a new brake disc, based on the application, its intended use, driver preference and a plethora of other technical requirements. The result; a range of different disc castings and/or configurations, each with their own characteristics and, critically, each designed to perform just like the OE...

Vented discs: Since brake discs absorb significant amounts of thermal energy, it’s critical that this heat is controlled effectively. Whereas solid discs rely on ambient air to do this, our vented discs feature special internal cooling passages to maximise airflow. By continually moving air across the disc’s surface or through the disc itself, they allow more heat to be dissipated, improving both cooling capacity and resistance to cracking from thermal shock. Unlike some other aftermarket brands, the venting vanes in discs are constructed exactly as the OE with the parting line in centre. Whilst this is more complicated and costly to cast, it provides much better braking balance and resistance to cracking.

Cross-drilled discs: In wet conditions, water acts as a cushion between the pad and disc, reducing friction and in turn stopping power. For this reason, our cross drilled discs feature additional axial holes on the friction plate. These holes help prevent a film of water forming for improved braking response in the wet. They also help to dissipate heat and any brake dust or gases that are generated when the pads come into contact with the discs. This helps to keep the pad surface both cool and clean and reduce thermal distortion, warping and brake fade.

High-carbon discs: By optimizing both carbon and silicon content, our high-carbon discs offer improved thermal behaviour, reducing the risk of thermal cracking under high-temperature loads, and allowing the discs to operate at a cooler temperature. Improved heat dissipation has the added benefit of also reducing distortion or warping, and in turn judder. And thanks to their high damping coefficient, they help reduce noise too.

Coated discs: Thanks to a special zinc-flake, silver Geomet coating across the entire surface, our coated brake discs offer both greater corrosion protection, compared with their oil-dipped or partially painted/coated equivalents, as well as improved aesthetics. The coating also stays in place longer, with salt spray resistance of up to 240 hours, versus less than 100 hours for many partially painted discs. And because they have no oil to clean off, they are easier and quicker to fit, saving valuable labour time and cost.

One-piece cast iron discs: Our one-piece cast iron discs offer an aftermarket alternative to the popular two-piece bi-metallic equivalent. Engineered from a single piece of high-carbon cast iron, instead of an aluminum hat and cast iron friction surface joined by metal rivets, they deliver the same standards of consistency, longevity and braking performance as the two-piece disc, but importantly are more cost-effective.

Discs with bearings: Some rear wheel applications use brake discs with an integrated wheel hub and bearings. Since these are inherently difficult to replace, we offer a range with these safety critical components already pre-mounted. This avoids damage to the bearing whilst removing it from the old disc, and the correct pressing in into the new. They also come with both toothed and magnetic ABS sensor rings integrated into the disc bearing, where fitted as OE, and the relevant fixing accessories. All for quick and accurate installation.

We like to think of this as our own discography; a range of finely-tuned, chart-topping discs, each with their own unique features and benefits, and each designed to perform like the OE. So, whether it’s coated, cross drilled or any combination of the above, you can install Delphi brake discs with complete confidence.

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi product range

Find out where to buy Delphi parts