Brake Drums & Shoes

- Product Information

- Product Resources

- Enquire

- Related Products

Quality materials

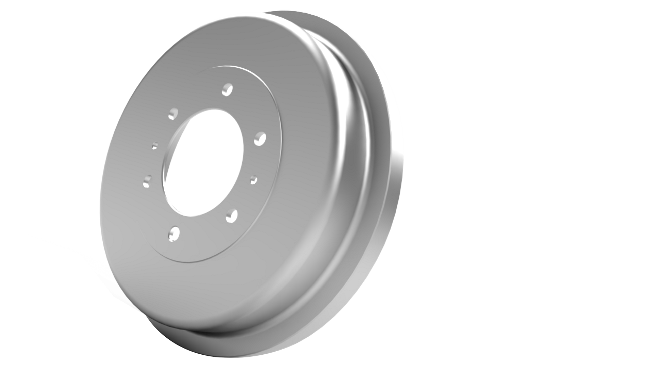

Delphi brake drums are precision manufactured on a digitally controlled production line, using only high-grade, heat-conductive cast iron. Since heat builds up within the brake drum under heavy braking, reducing its performance, choosing a drum with excellent thermal properties, such as Delphi’s, is essential.

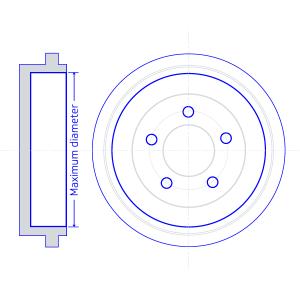

Easier servicing brake drums

As the brake shoes wear material from the drum’s surface, its diameter increases. For ease of servicing, and quick identification of parts that need replacing, all our drum brakes are marked with the maximum diameter, in addition to a traceability code.

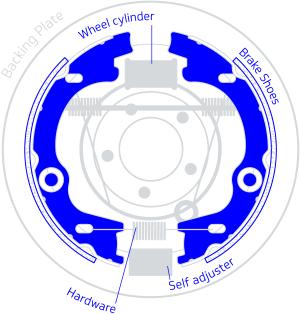

Best-practice drum repairs

For a quick and accurate repair, we also offer a range of drum and shoe kits in un-assembled, pre-assembled or pre-mounted formats. Including the key items needed for a professional and efficient service - shoes, adjustor bars (in pre-assembled and pre-mounted kits only), wheel cylinders and a fitting kit containing springs and clips (fitted to the back plate in pre-mounted kits), they help to ensure a best-practice repair, while offering significant labour and ramp savings.

The Delphi Difference

-

100 years of OE experience, supplier to the world’s top automakers

-

OE heritage and knowledge built into every aftermarket part

-

Comprehensive portfolio for a wide range of vehicles and model years

-

Streamlined SKUs for easy inventory management

-

Support through tools, tips and training

Related product resources and downloads

Visit our Technician Library for access to Documents and Downloads

Get in touch

The full Delphi Brake product range

Find out where to buy Delphi parts